Solid-state metal 3D printing specialist Fabrisonic has utilized its compact SonicLayer 1200 3D printer to create better value satellite heat exchangers for NASA’s Jet Propulsion Lab (JPL).

Instead of using its standard SonicLayer 7200 to produce the thermal regulators and their complex internal geometries, Fabrisonic opted to deploy its smaller, more efficient machine. The resulting components proved not only to be more cost-effective, but their seals have passed the JPL’s stringent testing, including a simulated Atlas V rocket launch.

Fabrisonic’s ongoing NASA partnership

Founded in 2011, Fabrisonic is a metal 3D printing service provider that fulfills orders using its proprietary Ultrasonic Additive Manufacturing (UAM) process. The hybrid manufacturing technique essentially involves ultrasonically welding metal tapes into layers, and once the object takes shape, using CNC machining gives it more complex features.

Given that the technology operates at low temperatures, it’s sometimes utilized to 3D print integrated electronics, and the company recently experimented with fabricating larger hybrid structures. More commonly, though, the process is deployed within aerospace applications, and Fabrisonic has partnered with NASA on several occasions.

Working with Luna Innovations, for instance, the company managed to 3D print sensors directly onto a NASA fuel pipe, while in a separate SBIR project, it’s currently developing UAM corrosion-resistant cladding. Now, as part of its most recent NASA collaboration, Fabrisonic has leveraged its UAM process to create yet another end-use spacefaring component.

Creating the heat regulating devices

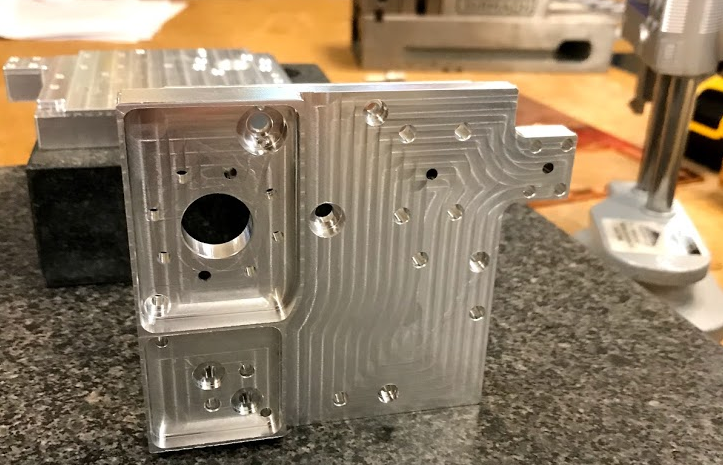

In its latest NASA project, Fabrisonic was commissioned via Utah State University’s (USU) College of Engineering to develop two unique parts for a thermal satellite system. Although fully-hermetic components have previously been realized using Fabrisonic’s SonicLayer 7200 3D printer, this time, the firm’s engineers opted to use the 1200 machine, and its more cost-efficient 10 x 10 x 10-inch build volume instead.

During production, the team deployed a combined additive and subtractive approach, using CNC machining to create the parts’ complex fluidic channels, filling them with supporting material. Once in place, these supports effectively prevented any excess metal from being extruded into the devices’ cavities while they were being printed.

After post-processing, in which the support material was washed out, the parts were machined into their final shape, leaving exchangers with smooth, accurate fluidic passages. To test that the devices were hermetically-sealed and leak-proof (something that’s essential to its end-use application), they were then subjected to rigorous JPL testing.

Ultimately, the parts conquered a series of tests, including being submerged underwater, subjected to 50 psi of pressure and a simulation of the vibrations experienced onboard the Atlas V. Having passed initial evaluations, the devices are now on their way to USU for final testing, where a helium leak detector will be used to simulate the vacuum of space.

Rise of the 3D printed heat exchanger

3D printing has been used to produce many different heat exchangers over the years, with applications ranging from automotive to clean energy generation.

In October 2017, French chemical firm Air Liquide won an award from the European Federation of Chemical Engineering (EFCE) for its 3D printed heat exchanger. By steam reforming natural gas, the additive manufactured reactor was reportedly able to increase the efficiency of its hydrogen production process.

Similarly, GE Research, the R&D wing of American conglomerate GE, has used 3D printing to produce an ultra-low-emission heat exchanger for power generation applications. The advanced additive device was created as part of a two-year project, that aims to make power plants both cleaner and more efficient.

Other 3D printing industry enterprises including Farsoon have also experimented with optimizing heat regulation devices, and the Chinese company 3D printed a copper proof-of-concept in 2019. By fabricating the complex spiral-shaped device as a single part, Farsoon was able to reduce its total cost by around 35%.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the heated exchanger, produced using a Fabrisonic 3D printer. Photo via Fabrisonic.