Fabrisonic, an Ohio-based company specializing in metal 3D printing, has taken a step closer to Mars. Fabrisonic’s used its patented technology to additively manufacture heat exchanger devices. The metal 3D printed components have now passed NASA’s quality control tests and are ready for flight in space.

Fabrisonic used Ultrasonic Additive Manufacturing (UAM), an additive manufacturing and subtractive technique, to build a heat exchanger, a device designed to control and regulate the temperature of an interplanetary vehicle’s electronic system.

Traditional methods of building heat exchanger devices are labor-intensive and time-consuming. The manufacturing process can take up to nine months. With the UAM process, Fabrisonic 3D printed a heat exchanger that is 30% lighter.

NASA approval means that the Technology Readiness Level (TRL) of the device has increased from 3 to 6. TRL is a framework for measuring the technological maturity of a given technology.

Most of the research took place at NASA’s Jet Propulsion Laboratory (JPL) in California, dedicated to construction and operation of planetary robotic spacecraft, and Earth-orbit missions. The technical details of the research were published in the paper titled Space-grade 3D Metal Printed Heat Exchangers.

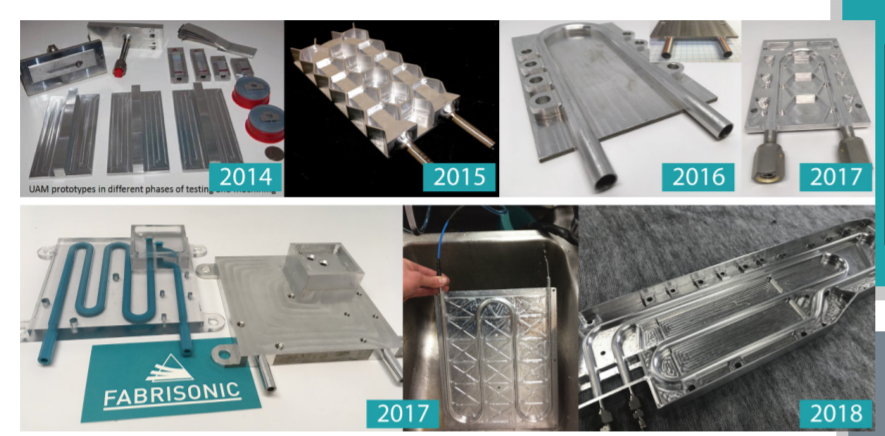

Fabrisonic UAM heat exchanger

Heat exchanger devices range from small (3 in. x 3 in.) to large (3 ft. x 3 ft.) structures. They are built using metal tubes glued and fastened to the outside of a vehicle such as a Mars rover. The purpose of this device is to protect the electronic system of the vehicle from extreme temperatures it will experience in space.

In 2014, Fabrisonic was awarded a JPL R&TD grant by NASA to design and build a heat exchanger using Fabrisonic’s UAM technology.

The UAM process uses ultrasonic welding to bond dissimilar metals, it is a unique additive manufacturing process in this regard. Computer numerical control (CNC) milling for subtracting the material after the additive process. Hence, the technology is a hybrid of additive and subtractive processes. The UAM process uses “high frequency ultrasonic vibrations to scrub metal foils together layer by layer.”

Ultrasonic additive manufacturing

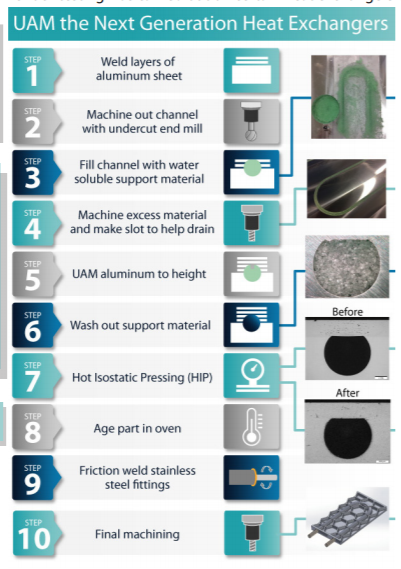

The process of making a heat exchanger with UAM begins with a metal substrate to which material is added. The material is then removed from the initial structure to make fluid passageways. At a later stage, the passageways are filled with a proprietary water-soluble solution for additional support. Finally, the structure is treated with heat, and CNC machining adds the final touches.

The UAM process is solid-state. It can work with most metals at a low temperature of 250 Fahrenheit. This allows bonding of varying materials like copper with aluminium. Within the same heat exchanger, copper can be used in specific places where temperatures are higher and aluminium could be used to keep the device lighter and in places where the heating temperature is lower.

The low-temperature solid-state UAM process also allows for sensors to be embedded in a heat exchanger since the process does not melt the metals.

NASA’s 3D printing projects

3D printing technology features frequently in NASA’s projects. Earlier this year, NASA awarded a grant to the American-based company Made in Space, a microgravity 3D printer developer. The purpose of the project is to develop additive manufacturing solutions to sustain human spaceflight. NASA’s Jet Propulsion Laboratory also began a project to use 3D printed testing equipment to improve the health of Astronauts’ in space. Last month, NASA announced Phase 3 winners of its 3D printed Mars habitat challenge. A program to develop self-building and self-sustaining 3D printed habitats on Mars.

Please subscribe to our newsletter to stay on top of news related to 3D printing. You can also follow us on Facebook and Twitter.

Visit our 3D printing job site to start a new career.

Featured image shows a Fabrisonic heat exchanger device. Photo via Fabrisonic.