Peter Troxler is one of the contributors to a collaboration of writing on 3D printing collected in The Decentralized and Networked Future of Value Creation. The collection, edited by Jan-Peter Ferdinand, Ulrich Petschow and Sascha Dickel aims to grasp the current rise of 3D printing and discuss the technology’s impact on the future of value creation. This article is part of a series where we will focus on each chapter of the book. So lets dive in!

Fabrication Laboratories (Fab Labs)

Troxler’s contribution, titled Fabrication Laboratories (Fab Labs), explores the rise and impact of publicly accessible workshops on 3D printing and the community surrounding it.

“Fabrication Laboratories (Fab Labs) are publicly accessible workshops offering digital manufacturing technology and electronics tools to anyone. Fab Labs continue a tradition of places for do-it-yourself (DIY) with technology for tinkering and inventing. They stand at the beginning of what has become known as the ‘Maker Movement’. Fab Labs aim to be the places where digital manufacturing know how is shared among their users. Particularly in Europe the Fab Lab concept has inspired grass-roots communities to set up such workshops. Fab Labs have been instrumental in promoting 3D printing, since these were the places where 3D printers were available to the public. Some Fab Labs were also involved in iconic 3D printing projects and developing and improving 3D printers. However, most of the current activities in Fab Labs remain recreational or educational. Meanwhile new models for collaborative production are slowly developing. Some technical, economic and social challenges have to be resolved. And Fab Labs will have to work actively on becoming economically, socially and ecologically sustainable.”

The history and origin of Fab Labs

The history of Fab Labs is pretty interesting. They first emerged from a research programme at MIT which explored the boundary between computer science and physical science and studies how to turn data into things, and things into data. Initially, only a handful of field Fab Labs were planned to be set up, but once the concept of a public space where one could make almost anything came out, the overwhelming appeal drove the creation of hundreds of labs around the world (there are currently 672 Fab Labs worldwide). The general purpose of a Fab Lab is to inspire and empower people to design and make what they cannot buy in stores.

The network approach of Fab Labs and the requirement to share designs and processes set them apart from similar workshops like MakerSpaces and the Techshop chain, as Fab Labs are one of the rare real world examples of decentralised and networked value creation that operate on a global scale and in the physical realm.

Digital manufacturing technology has not yet reached the home in the way PC’s have, says Troxler. Fab Labs are essential in providing a space and resources for hobbyists and entrepreneurs to utilise 3D printers and other manufacturing equipment without having to invest in potentially expensive hardware and education.

Troxler attributes the successful growth of the Fab Lab community to “the revival of publicly accessible DIY workshop spaces, the rise of the maker movement and an emerging awareness for value creation in communities.”

The evolution of DIY can be attributed to the capabilities of technology. Humans are generally hardwired to want to create, and when new technology comes along, we want to appropriate it for our own needs. Cooking, knitting, home improvement; the concept of DIY is not a new thing. With the introduction of Fab Labs, more technologically diverse projects can be tapped into by the general public for their own needs and interests.

The maker movement is also an important point to consider. The rise of shared information and resources encourages collaboration on projects, and Fab Labs helped fill a demand for physical spaces in which to do this. The maker movement is also said to be part of a bigger, socio-economical development towards a collaborative, sharing, peer-to-peer economy: Troxler likens Fab Labs to enterprises such as Uber and Airbnb.

The sharing of knowledge and ideas for this technology typically needs to take place in a physical space: much more can be conveyed and taught in person rather than online.

“The idea of physical peer-to-peer production—manufacturing that takes place in communities rather than factories, that treats manufacturing knowledge as a commons rather than a production factor—is not necessarily inherent in the maker movement. It is rather a projection or extrapolation of developments that have taken place in other industries—open source software or Wikipedia are commonly known examples. Peer-production of software and encyclopaedic content is thriving on an infrastructure of networked personal computers and on people engaging in social and collaborative endeavours. In analogy to personal computing, 3D printing is enabling personal manufacturing. Fab Labs and makerspaces stimulate social and collaborative endeavours, at least on a local basis.”

The importance of spaces like Fab Labs lie in the physicality of the project being undertaken or the object being made. Bringing people together in a physical space allows a better environment for commons-based manufacturing and the development and exchange of relevant knowledge and experience.

By the people for the people

Between 2001 and 2004, the global network of Fab Labs being set up were initiated by the Center of Bits and Atoms in collaboration with some other host institutions. They were fairly central in how they were run, and adhered to certain recommendations regarding equipment and operating principles. Troxler goes on to explain how Fab Labs also became community-based and community-run places that work towards the liberation of technological knowledge and related practices.

“It was only in 2010 when Fab Lab Amersfoort was founded that this grass-roots mode of setting up and running a space was for the first time adopted in the Fab Lab network. Under the title “The Grassroots Fab Lab Instructable or how to set up a Fab Lab in 7 days with 4 people and about €5000” they published their 116 P. Troxler approach which they called “extreme bottom up”. By making active use of an existing group of enthusiastic artists, inventors and tinkerers they were able to skip at least a year of preparation.”

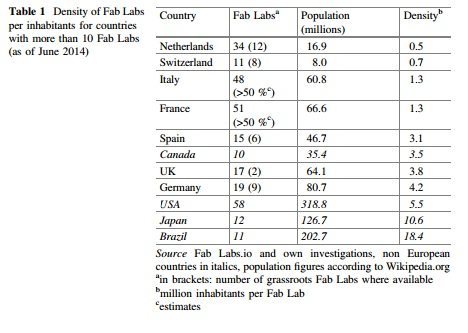

The “Grassroots Fab Lab Instructable” had a major impact on the adoption and development of Fab Labs, particularly in Europe. A recent study conducted by Troxler showed that almost half of all Fab Labs in Europe now are grass-roots operations, community labs that have been started and are run by their users, not by a pre-existing institution. The grass-roots approach also accelerated the rate of adoption in countries such as France, Italy and Switzerland.

Troxler also explains that while the grass-roots concept wasn’t initially part of the plan by the Center of Bits and Atoms, it works well in tandem with CBA’s approach.

Introduction of 3D printing to Fab Labs

The technical capabilities of Fab Labs evolved over time, beginning with things like laser cutting, vinyl sheet cutting, precision three-dimensional milling and electronics, Troxler says. The rise in interest in 3D printing meant it was adopted by Fab Labs, but only became an official part of its inventory recently (around 2013).

Troxler then goes on to explain how important public spaces like Fab Labs and hackerspaces were to early adopters of 3D printing, making a new technology much more accessible to the masses. You didn’t need to be rich or an expert to begin to experiment with 3D printing. Fab Labs have played a major role in the development and diffusion of low-cost and low-resolution 3D printing.

Public and media perception

Troxler spends some time talking about how the public and media perceived 3D printing between 2008 and 2014, the prime time when Fab Labs came into being, and how it was mostly smaller written pieces based on human interest stories. Subjects like printing food in space and prosthetics for children helped capture the imagination of the public and raise interest in 3D printing, but facts were often mixed up and enthusiasts working with the technology were labelled as experts in the field.

This is an interesting section, and it is good to note how far the technology has come in terms of media perception in just a few short years.

Scope of applications in Fab Labs

In this segment, Troxler concludes that at this point in time 3D printing activities in Fab Labs are mainly recreational and educational. Commercial use appears to be exploratory rather directly business oriented. The value of Fab Labs for businesses is not access to the equipment—as it is for hobbyists—but to access other inventors and innovators and participation in an environment that stimulates creative exchange and co-creation of solutions.

He goes on to say that:

“Different studies find that a large proportion of Fab Labs do not operate as financially independent organisations, depend largely on public funding or are not even financially sustainable at all. As such they appear to be mainly oriented towards locally sharing knowledge and educating their rather diverse clientele which includes students, hobbyists, free lancers, and firms. Financially self-sustainable, independent Fab Labs—i.e. labs that typically generate more than three quarters of their income from commercial income—cater primarily for hobbyists. A source confirms this as the three top sources of income are membership fees, workshops, and government subsidies, with contracts with corporations at the end of the list. These are interesting findings as a possible interpretation is that Fab Labs currently do not sustainably support commercial activities carried out by people who would identify themselves as freelancers or representing firms or that would be supported by commercial contracts. The high rate of public funding supports this interpretation when one assumes that public funding would mainly be applied to activities that cannot be commercially supported.”

Sharing, limitations and implications for sustainability

Troxler spends the rest of his chapter talking about the concept of sharing and collaboration in Fab Labs, both in the physical space and online. He also discusses the limitations of the widespread adoption of 3D printing. As far as he can see, the 3D printing technology used in Fab Labs is still pretty basic. The 3D printers used have limited build volume, build speed and accuracy. Because of the nature of the spaces, the machines used need to be accessible to hobbyists. This limits the level of complexity they are able to offer with their printers, software and printing materials. Money is also a factor, as Fab Labs aren’t generally designed to create revenue. Independent self sustaining Fab Labs rely heavily on hobbyists that will spend money for access to technology and resources they wouldn’t otherwise have.

Troxler concludes his piece on Fab Labs by delving into the implications for sustainability – economically, socially and ecologically. It’s an interesting section that raises questions of the future and evolution of 3D printing and Fab Labs.

He goes on to say that for Fab Labs to contribute to economic sustainability there needs to be a development away from depending on public subsidies and towards developing value propositions that allow labs to become economically self-sufficient.

In terms of contributing to social sustainability, they need to pursue their path of individual empowerment. They need to actively pursue social innovation in conjunction with gaining economic stability. The industry needs to move away from a user society to a maker society, to be able to utilise the full potential of Fab Labs and the related community.

Ecological sustainability is a tricky one, with there being limits to materials that are environmentally friendly. Troxler says that research on sustainability in Fab Labs has only recently started and the conclusion so far is that it remains to be seen if Fab Labs are able to transform themselves into a platform for participatory ecological innovation.

Future potential of Fab Labs

“Fab Labs, initially set up as places where ordinary people could access cutting edge technology to become inventors and innovators have a potential that goes beyond providing technology to all. They are already becoming places where people share their inventiveness and engage in co-creation practices. Beyond developing technical fabrication skills, the Fab Lab public (its users, clients, participants, members?) develops skills for social fabrication which include “Do It With Others” (DIWO) and co-creation, but also more subtle forms of informally advising others on their inventions—and asking others for advice.”

This chapter by Peter Troxler brings together the idea of shared information and the implementation of this knowledge in an accessible public space for all, and is an excellent read in its entirety.