Essentium, the OEM behind the High Speed Extrusion (HSE) 3D printing technology, and NUBURU, a specialist in industrial lasers, have partnered to develop a new blue laser-based metal 3D printer.

Designed to enable industrial-grade metal parts with high resolutions and throughput, the upcoming printer will reportedly be developed under a ‘multi-year, multi-million-dollar’ deal. According to the partners, the system will be suitable for a wide variety of critical industries such as automotive, aerospace, and defense.

The machine will integrate NUBURU’s proprietary blue laser technology and be capable of processing materials in wire feed form, so we can deduce that it’ll operate on a variant of directed energy deposition (DED) technology. In fact, NUBURU will go so far as licensing its 3D printing application patents to Essentium as part of the contract.

“We are excited to work closely with the Essentium team and combine the powers of our existing technologies to develop and manufacture a new transformative platform for additive manufacturing,” said Mark Zediker Ph.D., co-founder, CEO, and President at NUBURU. “Our high power, high brightness blue laser technology, along with our 3D printing IP will help Essentium build a powerful metal 3D printer with a wide range of applications.”

Going beyond HSE 3D printing

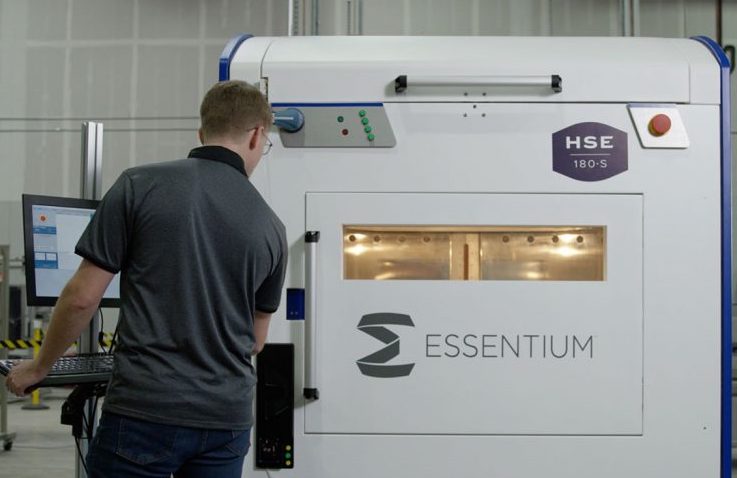

Until now, Essentium’s main business has revolved around its HSE technology, a form of high-speed, high-temperature FFF suitable for engineering filaments. As such, the launch of the upcoming blue laser 3D printer will mark Essentium’s debut in the metal 3D printing space.

Backed by eight patents to date, the firm’s existing product portfolio is currently three-strong and includes the original HSE 180-S 3D printer. Available in three different versions, the 180-S is aimed at firms seeking high-volume polymer and composite production. It features a build volume measuring 690 x 500 x 600mm and the machine is well-suited for everything from high-strength jigs and fixtures to prosthetic sockets and orthotic devices.

On the other hand, the 240 HT Dual Extruder 3D printer is designed to be small enough to house in compact factory spaces and university labs. The machine sports a build volume of 430 x 350 x 375mm.

Finally, the 280i HT system is characterized by its large build volume, rapid print speeds, and extensive material capabilities. Aimed at high-volume manufacturers in sectors such as aerospace, electronics, automotive, and consumer goods, the system is also described as a ‘true IDEX’ 3D printer, whereby the printheads are independent in both the X and Y-axes.

What’s the deal with blue lasers?

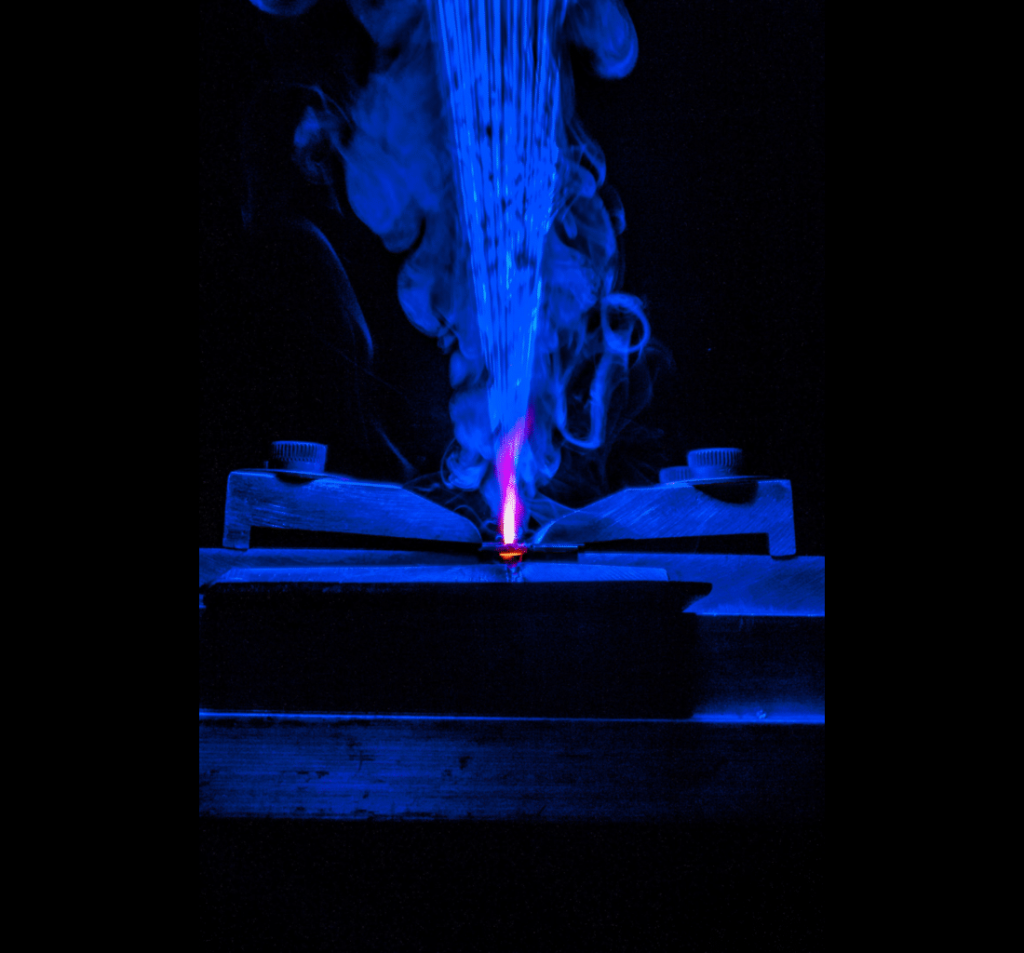

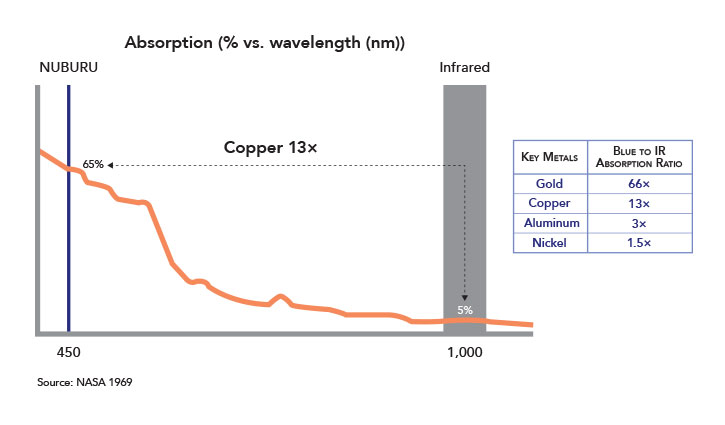

So what’s so special about NUBURU’s blue lasers? Alloy metals such as copper, stainless steel, and aluminum are known to reflect a large portion of the energy from infrared waves and other colors of light. As such, the use of traditional laser diodes can result in poorer print quality as well as lower print speeds, as energy isn’t transferred as efficiently.

On the other hand, metals like copper absorb blue light much better than the other wavelengths so the use of a blue laser can melt these materials much faster. As a result, NUBURU claims its blue laser technology can enable 3D printing speeds up to ten times faster than competitors, all while granting the ability to print with a very high metal density.

According to Essentium, the new 3D printer will produce parts similar to traditional castings and forgings and require ‘minimal post-processing’.

“NUBURU is the leader in blue laser technology, and their expertise will help enable gains in speed and power within our new platform,” said Elisa Teipel, Chief Development Officer and co-founder of Essentium. “We are looking forward to working with their team and leveraging their technology, enabling Essentium to commercialize a new metal 3D printing platform.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a NUBURU blue laser. Photo via NUBURU.