3D printing is often championed as a method for creating customized one-offs and it doesn’t get much more customized than the European Southern Observatory’s Very Large Telescope in Chile. In astronomical optics, especially for a telescope of the VLT’s stature, complex one-off parts are necessary for an instrument’s operation, but can be very expensive to produce and take a great deal of time to receive. Thanks to a 3D printing and investment casting, however, the VLT was able to produce two essential components for a better price and much more quickly.

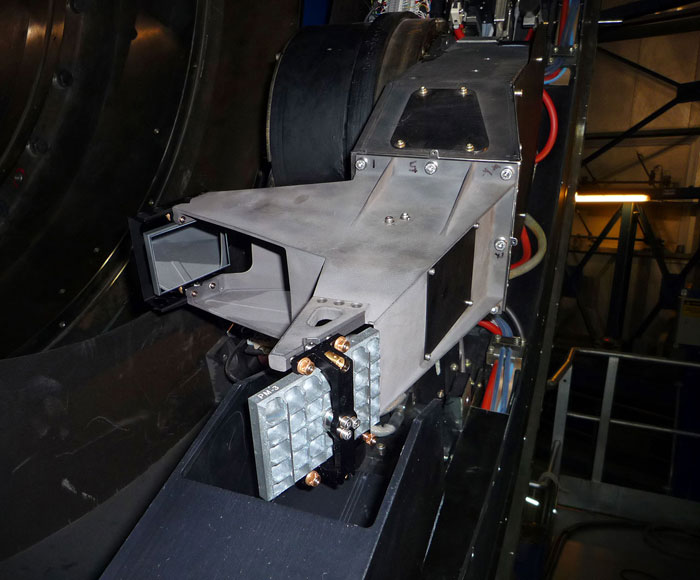

One of the components was a new sensor arm to be installed into the telescope in order to work with the ESO’s MUSE instrument — a panoramic integral-field spectrograph for studying galaxies — in addition to an optics module to be installed in 2015, called the GALACSI — meant to enhance the MUSE. The metal sensor arm holds three flat mirrors that direct light into sensors on the VLT, guiding it during observations.

To create the part, German large-scale 3D printer manufacturer voxeljet 3D printed a model of the part to be cast in a thermoplastic, polymethlmethacrylate. Then, wax is used to create a negative of this shape by pouring it into the plastic print. The wax mould is then coated in a heat-proof ceramic and melted out, resulting in a treated and hardened die from which to create the final metal cast. The new sensor arm was made from high grade aluminum to replace its highly toxic beryllium predecessor, which could not be modified safely after it was installed.

ESO’s second component will be a spacer for the VLT’s test camera, manufactured by German metal casting company, ACTech GmbH. While the spacer will be made via investment casting from ductile cast iron, the original model for its mould will be crafted from the selective laser sintering process.

Source: ESO