Engineers at the Ecole Polytechnique Fédérale de Lausanne (EPFL) have successfully printed an opaque resin on their volumetric 3D printing system for the very first time.

Developed at the EPFL Laboratory of Applied Photonic Devices (LAPD), the volumetric 3D printer has only been compatible with homogeneous and relatively transparent resins to date. Using computational methods, they’ve now programmed the printer to be able to compensate for light-ray distortions mid-build, which has long been an issue with opaque resin materials.

With the latest breakthrough, the researchers will be able to fabricate complex objects made of opaque resins in a matter of seconds. They expect the work to have major implications for applications in bioprinting, including cell-laden constructs such as artificial organ models.

The speed of volumetric 3D printing

Conventional resin-based 3D printers operate on the classical layer-by-layer approach, whereby horizontal layers are printed and stacked onto each other to form 3D parts. Although this tried-and-tested method is reliable, it still suffers from relatively slow print speeds thanks to the curing times of each layer.

Volumetric 3D printing, on the other hand, takes a fundamentally different approach. Rather than depositing materials in layers, volumetric systems simply print directly into the resin vat from multiple angles at the same time, curing the entire 3D object at the intersections between the various light sources.

Christophe Moser, a professor at LAPD, explains, “We pour the resin into a container and spin it. Then we shine light on the container at different angles, causing the resin to solidify wherever the accumulated energy in the resin exceeds a given level. It’s a very precise method and can produce objects at the same resolution as existing 3D printing techniques.”

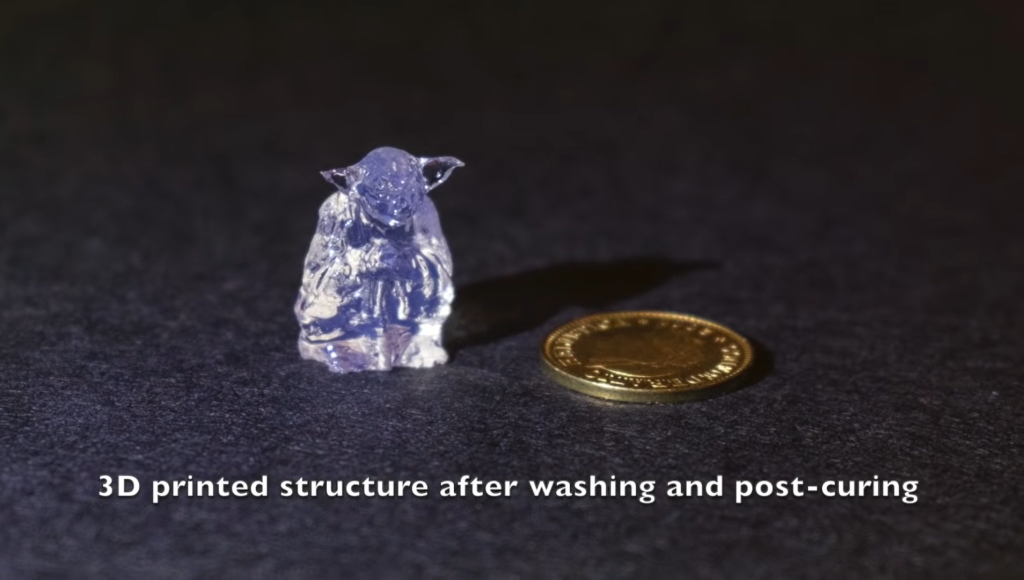

To get a sense of how fast volumetric 3D printing is, the EPFL engineers have already 3D printed a tiny Yoda model in just 30 seconds. Using a standard SLA machine, the same build would’ve required around ten minutes.

Correcting light ray scattering

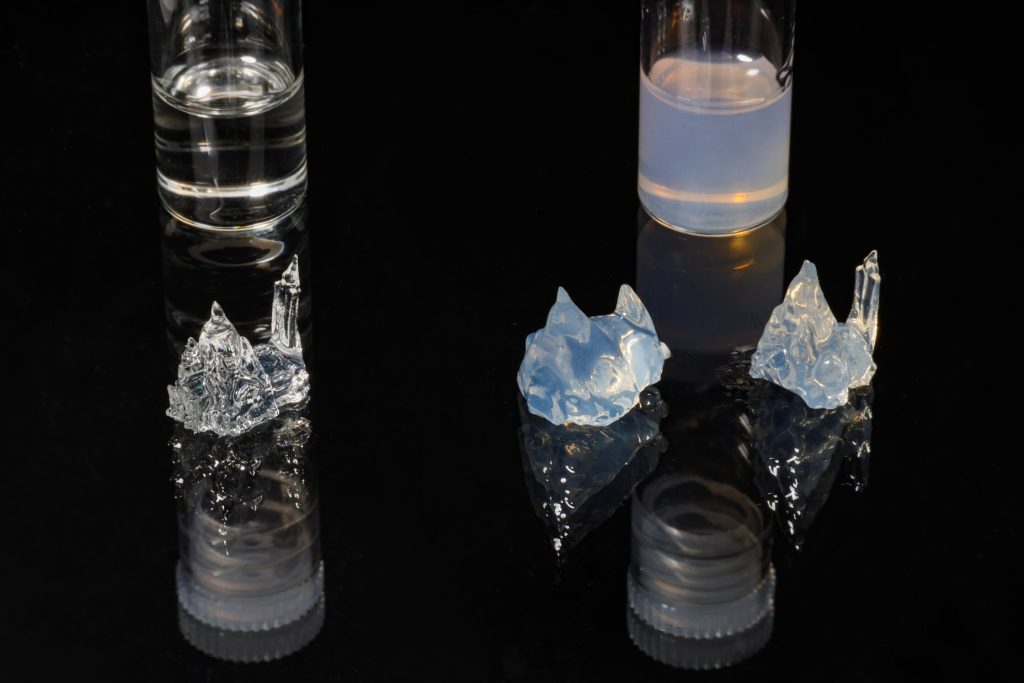

Since the resin-curing light rays need to interact with the photosensitive compounds in the material, volumetric methods like EPFL’s only work when the light passes through in a straight line without being deviated. In essence, they require transparent resins. The engineers have previously tested opaque resins but found that light propagation wasn’t clean, leading to insufficient photopolymerization.

“With opaque resin, we lost a lot of resolution in the printed object,” says Jorge Madrid-Wolff, a Ph.D. student at LAPD. “So we tried to come up with a solution that would let us fabricate objects in this resin but without losing the advantages of our 3D printer.”

To solve the issue of light ray distortions, the team used a camera to capture the trajectory of the printer’s light and developed algorithms to correct the scattering in-situ. They modified the printer to run these compensations with every build.

With the latest adjustments, the EPFL system can now ensure that sufficient photopolymerization energy reaches all of the necessary sections of the build chamber. The team can now use opaque resins and achieve almost the same part resolution as with transparent resins.

As far as future work goes, they intend to improve the technology’s resolution down to just a micron. There are also plans to one day implement multi-material 3D printing capabilities to enable even more applications.

Further details of the study can be found in the paper titled ‘Controlling Light in Scattering Materials for Volumetric Additive Manufacturing’.

Despite the unique capabilities of their 3D printer, the EPFL engineers aren’t the first to explore volumetric 3D printing. Last month, researchers from Stanford and Harvard University developed a new method of volumetric 3D printing capable of fabricating resin parts without the need for any support structures. The approach relies on a nanoparticle-laden resin material that only hardens when it’s blasted with a very focused laser spot.

Elsewhere, at Utrecht University, scientists recently fabricated working livers using a newly developed ultrafast volumetric 3D bioprinting method. Printed in less than 20 seconds, the liver units were able to perform key toxin elimination processes mimicking those that natural livers perform in our bodies, and could open new opportunities for regenerative medicine and personalized drug testing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the same part 3D printed in transparent resin (left), opaque resin without correction (mid), and opaque resin with correction (right). Photo via EPFL.