Robotic 3D printers are helping to advance the next generation of autonomous construction.

Recently, the 3D printing industry has seen houses 3D printed in 24 hours or less, and bridges materialising out of melted plastic.

BADGER is the latest of these projects attempting to bring 3D printing to construction.

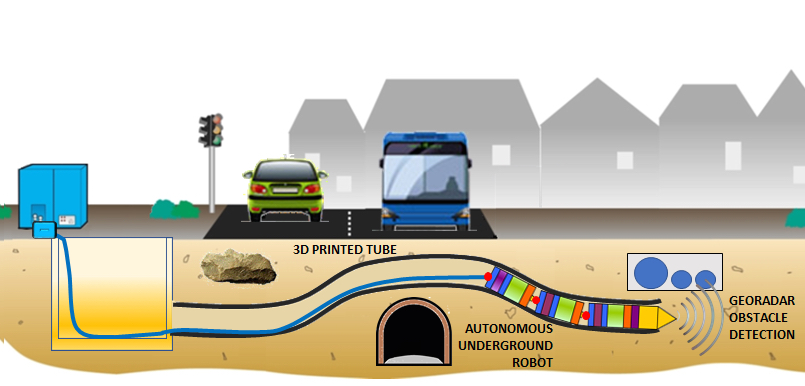

The Europe-wide enterprise brings together a group focused on building a robot capable of drilling and 3D printing tunnels for gas supply, telecoms cables and water pipes.

What is a BADGER?

BADGER is an acronym of the devised “roBot for Autonomous unDerGround trenchless opERations, mapping and navigation”.

Co-ordinated by the University Carlos III of Madrid, the project is supported by a consortium of seven companies and research institutions, including German ‘mole technology’ specialists Tracto Technik, and the University of Glasgow in the UK.

Horizon 2020

Development of the system started February 2017 after BADGER won one of eight places on the European Union’s Horizon 2020 Framework Programme for Research and Innovation.

Other projects to have won Horizon 2020 funding include a program for making customized eyewear, and Project BARABARA looking into the production of recycled 3D printer filaments.

As part of BADGER’s agreement, the EU granted the company €3.7 million (the equivalent of $4.38 million USD) in funding. This money will be spread over three-years.

Mole technology

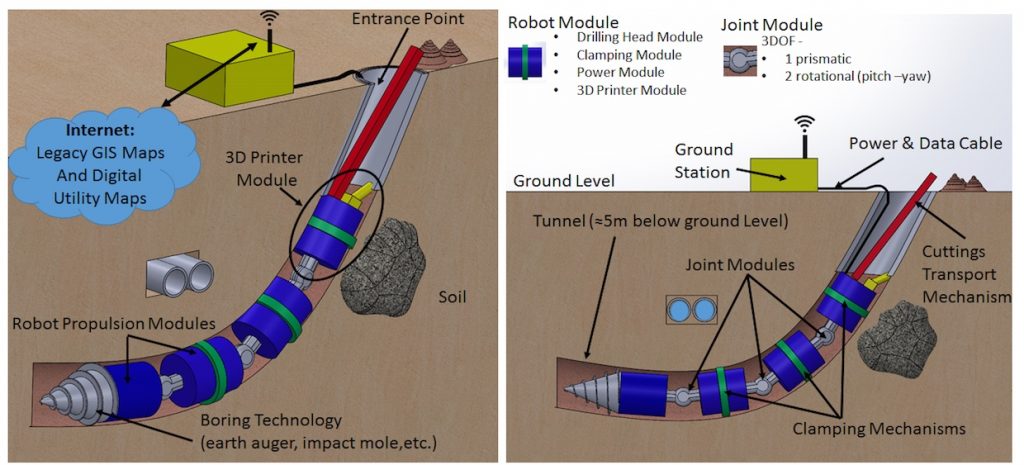

In current concept artwork, BADGER has four modules. At the head is a boring drill – a scaled-down version of the equipment used to make train tunnels.

In the center there are two clamping segments, designed to keep the drill in place as it bores though the earth.

The final segment is the 3D printer module. This module 3D prints walls in the BADGER’s wake.

On the project’s website, this module is defined as “a follower robot equipped with a printer head and a cylindrical manipulator” capable of constructing walls with “additive material (resin or other)”.

Underground navigation will be determined by an above ground substation, communicating with the drill using Ground Penetrating Radar (GPR).

The goal by the end of 2019 is to have a BADGER tunneling system that is autonomous, and ready-to-market.

To stay up to date with the latest Horizon 2020 3D printing projects and other industry news follow us on Twitter and like us on Facebook. The latest stories can also also be delivered direct to your inbox. Sign up to the most widely read newsletter in the industry here.

Looking for jobs in construction? Register on our 3D printing jobs site here.

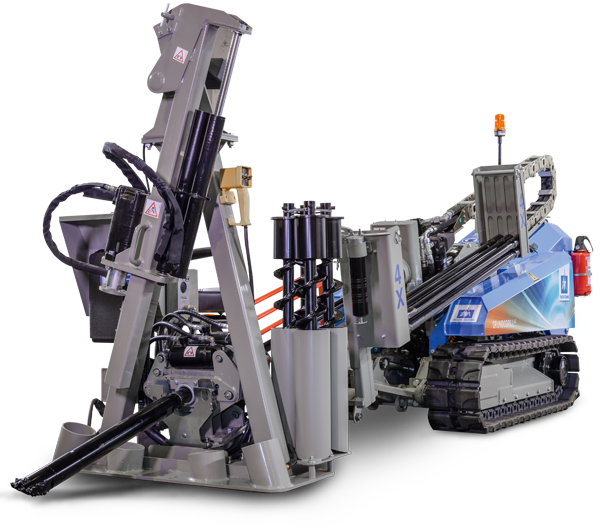

Featured image: The BADGER drill built for burrowing underground. Image via Badger Robotics