As one of the most impressive feats of civil engineering, bridges have become the ultimate goal of a number of projects in architectural 3D printing.

Last year, the 3D printing industry saw the construction of a reinforced concrete bridge made by the Institute for Advanced Architecture of Catalonia (IaaC). This year, TU Eindhoven have also risen to the challenge with a bicycle bridge.

Continuing with the trend, a team at Tongji University, China, has 3D printed two bridges as part of the 7th edition DigitalFUTURE Shanghai Workshop and Conference. This time though, the structures are made from plastic.

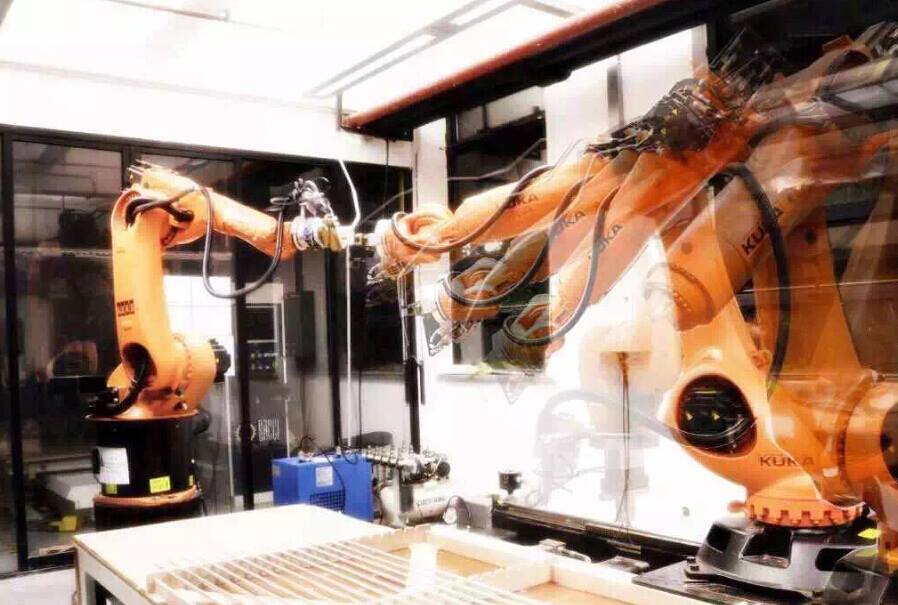

3D printed with robots

Both bridges were made by a team of students from the School of Architecture and Urban Planning at Tongji University. Professor Yuan Feng and Associate Meng Gang oversaw the project, alongside Zhang Lian from the FabUnion space in Shanghai.

The brief given by DigitalFUTURE Shanghai was “Visualization vs Materialization”. To fit this concept, the bridges were created digitally and 3D printed using a robotic arm – potentially making them a product of FabUnion’s 18-axes KUKA robot setup.

Strength engineered

The larger bridge is 11 meters long and capable of supporting the weight of up to 5 adults. The smaller version at 4 meters can support even more weight, as seen in the photo below.

Material used to make the structures is described as ‘modified plastic’.

Vaulting the competion

ETH Zurich and Zaha Hadid Architects also held a workshop at DigitalFUTURE Shanghai. Using the Rhino VAULT plugin, the collaborative challenged students to design an arched structure using 3D printed clay.

More of the printed and non-printed projects at DigitalFUTURE Shanghai can be found here.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Looking for more 3D printing near you? Check out our events calendar now.

Featured image: one of the 3D printed bridges and Tongji University. Photo courtesy Tongji University School of Architecture and Urban Planning.