Dyndrite Corporation, a Seattle-based software company, has launched the Dyndrite Accelerated Geometry Kernel (AGK), a fully Graphics Processing Unit (GPU) native geometry engine for CAD/CAM for 3D printing at the 2019 AMUG conference.

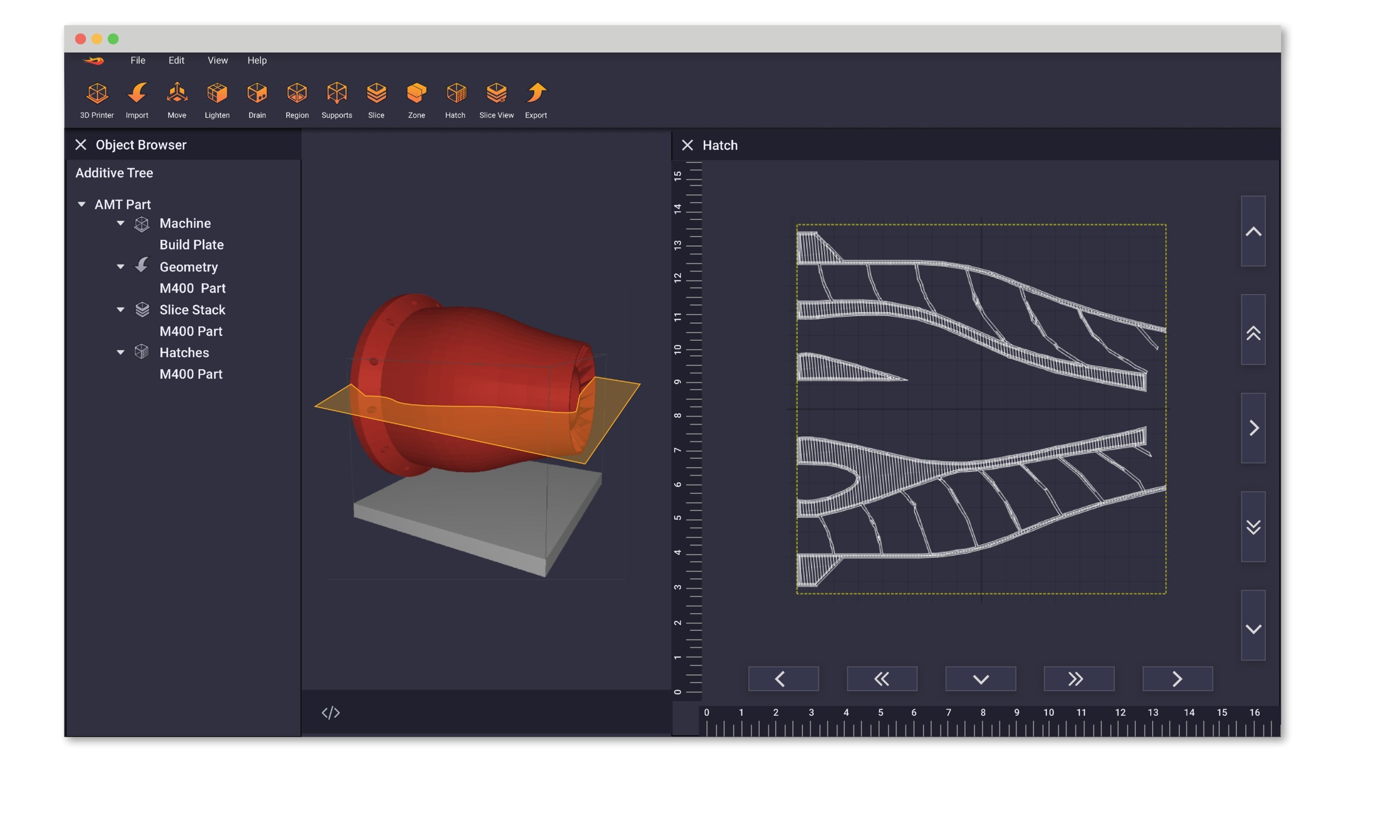

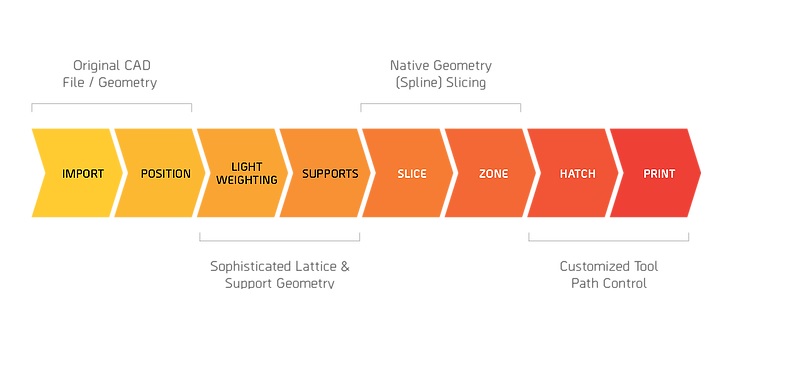

Built on the AGK is the Dyndrite Additive Toolkit, which enables a streamlined CAD-to-Print workflow for industrial additive manufacturing. The AGK is said to easily handle additive specific computations such as lattice, support, and slice generation, reducing design time.

“I’ve spent my career working on software built to enable designers, engineers, and technicians,” said Dr. Laura Lurati, Chief Scientist at Dyndrite.

“With the release of the Dyndrite platform, we dramatically improve the daily working lives of additive manufacturing users. I’m excited to see the innovative solutions our users create with these powerful new tools.”

The Dyndrite Accelerated Geometry Kernel

Following over three years of development, the team at Dyndrite has aimed to bring modern computing, language and capabilities to engineers in all industries with the AGK. This software is capable of representing all current geometry types, including non-uniform rational basis spline (NURBs) used in computer graphics for generating and representing curves and surfaces.

Furthermore, the AGK is naturally scalable with access to additional GPU nodes, locally and in the cloud. Through the Dyndrite Developer Program and Council, which includes Aconity3D, EOS, HP, NVIDIA, Plural Additive Manufacturing, and Renishaw, the company has established the AGK to advance the accessibility of the additive manufacturing.

“The Dyndrite Accelerated Geometry Kernel promises to do for 3D printing what Adobe and PostScript did for 2D printing in the 1980’s,” said Shawn Hopwood, Dyndrite’s Chief Marketing Officer and Head of Developer and OEM Relations.

“Laser printing technology powered by PostScript set off a revolution that forever changed how people communicate. In the new revolution, 3D printers powered by Dyndrite have the potential to change every aspect of the things we make, where we go, and how we live.”

Dyndrite AGK availability

Announced at AMUG 2019, the Dyndrite Accelerated Geometry Kernel is available to select developers and OEMs and will be available on a broader scale later this year.

Dr. Gregory Hayes, Director of Applications and Consulting for EOS added, “As EOS continues to break boundaries and push the frontier of additive manufacturing, we pride ourselves in forming collaborative relationships to be able to offer our customers the best and state-of-the-art technology.”

“We are excited to be working with Dyndrite, and looking forward to how their software can streamline and improve the design to part workflow.”

Vote now to decide this year’s winners of the 2019 3D Printing Industry Awards.

For all of the latest additive manufacturing news and updates, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image shows the Dyndrite Additive Toolkit within the AGK. Image via Dyndrite.