Italy’s DWS 3D printer company have launched the DFAB set of SLA 3D printers for use in dentistry. The Photoshade technology inside the 2 DFAB models allows dentists and prosthodontists to reproduce the natural appearance of a patient’s teeth using gradients of color.

The official launch of DFAB is being held by DWS at the 2017 International Dental Show in Cologne, Germany, from 21 – 25 March.

3D printed bridges in up to 20 minutes

The DFAB process to produce a dental bridge, ready for insertion into a patient’s mouth, follows five phases. As usual, an impression of the patient’s teeth is taken via an intra-oral scanner. This information is then imported into the dentist’s chosen CAD/CAM software to make an .stl file.

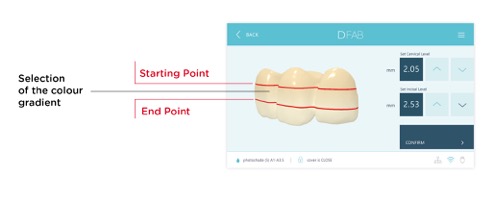

Once the .stl file is loaded into DFAB system, the intuitive software Nauta Photoshade takes the user through file editing. This includes the shading of the teeth, as explained by DWS,

The user sets the colours, choosing two gradients of maximum and minimum intensity, from the VITA*1 range between A1 and A3.5. The software Nauta Photoshade accurately reproduces the shades in order to obtain intermediate nuances for the most authentic result currently possible.

After this, the bridge is ready to 3D print, which typically completes in around 20 minutes. The supports are removed, and the bridge is finished – the teeth are ready for use.

The speed of DFAB means that dentists could provide a treatment completed within a single visit. It also cuts out the need for outsourcing to external dental labs, causing extended wait time.

40-micron accuracy

Teeth are 3D printed in DFAB using 40-micron laser spot (smaller than the width of a typical human hair). This ensures an accurate fitting, and correct occlusion of the teeth.

The material used for 3D printing is biocompatible Temporis. The mechanical strength of Temporis is comparable to existing resins used for this process, and comes in cartridges conceived with a sterilized workplace in mind. DWS explains,

Compared to the traditional systems, the disposable cartridge allows an easy material change and prevents unnecessary cleaning and maintenance of platform and resin tank.

Available as chairside and desktop versions, DFAB is also designed to fit with varied work styles for lab technicians and dentists alike. The systems will be available for sale from July 2017.

To stay up to date with the latest launches of 3D printers for dental use, sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

You can also vote now for the best 3D printers in the first annual 3D Printing Industry Awards.

Featured image shows the chairside and desktop versions of DWS’ DFAB. All images featured in this article are via DWS.