Formed by a couple of young designer with extensive experience in 3D printing, St3p3D is a small studio based in Glasgow that offers corporate services for 3D printed marketing and merchandising as well as an online service with price quotations for 3D printing STL files.

Euan Quigley and Dickon Walker, the two founders also use the expertise they have acquired using 3D printing to blog about what they do and give tips that can be useful to new 3D printing adopters as well as to their potential customers. In one recent interesting entry, Euan illustrated a few simple (and a few less simple) ways to strengthen a 3D printed part.

St3p3D’s bases its study on the premise of another study that supported the idea that desktop 3D printed parts can be as tough as industrially 3D printed ones, it is just a matter of taking a few careful steps in the various phases of the home manufacturing process: design, 3D printing and finishing.

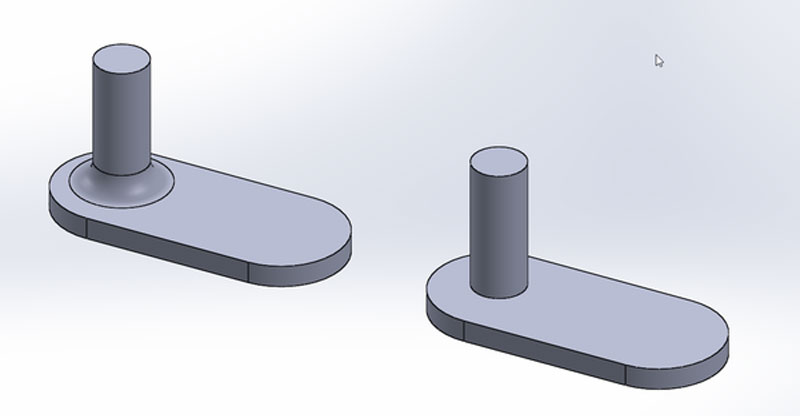

Quigley divides the process into four main areas. The first i model geometry and here the main concept is that if you want you piece to be stronger, generally you can achieve that by thickening. Alternatively you can also digitally insert fillets and rounds to add create a sort of lead-in to a thin section.

The second step is still software based but it is more directly related to 3D printing. It includes how you position the part inside the print bed (sometimes the best orientation is slanted), regulation of layer height (not always bigger layers mean more solid parts) and Infill percentage (higher infill percentages can add to resistance but also affect exterior appearance). The choice of material is also an aspect to be carefully considered: in certain case PLA can work better than ABS, and nylon is an increasingly valid option.

The trickiest parts are those related to the finishing and require familiarity with materials such as epoxy or polyester based resins as well as carbon fiber. Both can be used to coat the part and add considerable resistance to impacts and pressure but they are not always suitable. Quigley even describes heat treatment (with a blowtorch) as a possibile way to create stronger inter-layer bonds admitting, though, that this method may endanger the part.

The final option to make a 3D printed part stronger is by… not 3D printing it. Plaster casting (lost wax casting) and other types of moulding can be used along with 3D printing to create extremely durable though digitally designed parts. This also means a lengthy post processing but in certain cases it may be worth the time spent.

It seems interesting to note that, although it is directed at a wider audience, most of the advice handed out requires 3D modeling, mechanical and technical knowledge. The fact that a growing number of non-professionals are developing such experiences through desktop 3D printing is one of the most fascinating aspects of this technological evolution.