A 3D printed, shrunken Arc de Triomphe represents the result of the latest research undertaken by the Ke Functional Materials Group at Dartmouth College.

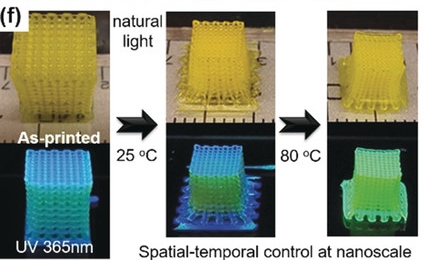

Focused on developing innovative materials for 3D and 4D printing applications, the Ke Group’s most recent ink makes objects that change size and color in reaction to external stimulus.

Though still far from producing an end-use article, the study lays important groundwork for scientists seeking to produce smart materials capable of self-assembly, and performing useful tasks in medical research, engineering and more.

Professor Chenfeng Ke, pricipal investigator of the Ke Group, comments, “While many 3D-printed structures are just shapes that don’t reflect the molecular properties of the material, these inks bring functional molecules to the 3D printing world,”

“This technique gives life to 3D-printed objects.”

Giving life to 3D printed objects

To make a shrinking, color changing Arc de Triomphe, the Ke Group uses a Direct Ink Writing method of 3D printing. Like FDM/FFF based techniques, an object is built up through the extrusion of successive layers, the main difference is the feedstock, and resulting operating temperature.

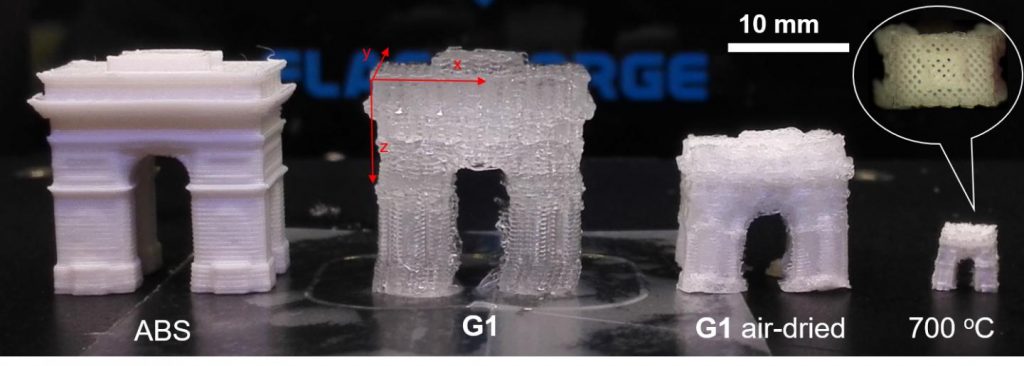

In the proof of concept experiment, a benchmark model of the Arc was FDM/FFF 3D printed in ABS and a second Arc, matching the scale of the ABS benchmark, was 3D printed in the lab’s specially developed G1 hydrogel ink.

As visible from the picture below, Direct Ink Writing produces a rough, yet discernible, structure of the Arc, at 300-micron resolution.

After air drying, and calcination (At a temperature of 700°C) the G1 Arc shrinks to 1 percent of its original size, with 10 times the resolution.

While rudimentary, the technique represents a step-changing possibility that could bring down the cost of industrial 3D printers. “This process can use a $1,000 printer to print what used to require a $100,000 printer,” explains Ke, adding that the “technique is scalable, widely adaptable and can dramatically reduce costs.”

The future of smart materials

In addition to shrinkage, models made using the G1 hydrogel ink can can be tuned to change color by adding fluorescent markers to the ink. The chameleon-like change is activated by shining a light on the surface.

“This is something we’ve never seen before,” adds Ke, “Not only can we 3D print objects, we can tell the molecules in those objects to rearrange themselves at a level that is viewable by the naked eye after printing,”

And, importantly,

“This development could unleash the great potential for the development of smart materials.”

Further reading

Previous research from the Ke Group at Dartmouth College includes the fabrication of an expanding hydrogel capable of lifting objects heavier than its own weight.

“Hierarchical Co-Assembly Enhanced Direct Ink Writing” is published online in Angewandte Chemie journal where it has been tipped as a VIP (Very Important Paper). The paper, as discussed in this article, is co-authored by Dr. Longyu Li, Dr. Pengfei Zhang, Dr. Zhiyun Zhang, Qianming Lin, Dr. Yuyang Wu, Alexander Cheng, Yunxiao Lin, Dr. Christina M. Thompson, Prof. Dr. Ronald A. Smaldone and Prof. Dr. Chenfeng Ke.

For more related research and news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking to get involved in a new project? Join 3D printing jobs for the latest vacancies in software, hardware and materials.

Vote now in the 2018 3D Printing Industry Awards for research/academic of the year and more.

Featured image shows A model of the Arc de Triomphe 3D printed in Dartmouth’s special hydrogel (right), and the same model after air drying (right). Image by Chenfeng Ke