Generative exoskeleton concepts are one of the most recognizable (and coolest) examples of the high level of personalization possible with 3D printing in the healthcare field. The new 3D printed orthoses developed by CRP Group and design studio MHOX take these concepts to another level, one that is closer to commercial reality.

Orthoses are not exoskeletons. They are braces used in orthopaedics to support, align, prevent or correct deformities or to improve function of movable parts of the body. Most often they are seen around the neck to treat injuries to the cervical spine. MHOX created one for hands, to aid rehabilitation after surgical operation and one for legs, for patients with peroneal muscles deficits and consequent troubles in their gait cycle (the walking cycle).

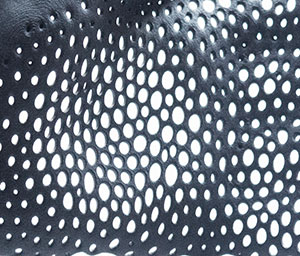

Both concepts were produced using CRP Group’s Windform GT material for laser sintering. The polyamide-based material integrates glass fibres: its elasticity, impermeability and durability make it an ideal choice for this type of medical application.

These very particular concepts were developed in collaboration with medical professionals. The entire process is based on three phases. First the patient gets his limb 3D scanned, then the 3D model of the orthosis is generate digitally using MHOX’s proprietary software, finally the orthosis is 3D printed by laser sintering using CRP’s materials and facilities.

The scan can be performed on location, right in the doctor’s studio or even in a surgery, using low cost and portable infrared based 3D scanning systems. The 3D scan allows the object to embrace both the leg and the foot, directly integrating a plantar. A specific joint, centered on the ankle, whose geometric characteristics vary parametrically from patient to patient, employs the flexibility of the material to provide active support and control in the gait cycle.

MHOX’s generative design techniques simulating biological phenomena make it possible to 3D print the bespoke orthosis to mimic the patient’s body to perfection, while optimizing and reducing costs, time and materials required.

Not to mention that the generative orthosis just looks awesome. The same method can and will be used for prosthetic fairings (such as the one’s by UNYQ) and reach extreme levels of personalization. In the future similar systems may be used to treat even more complex injuries and nerve or muscle related pathologies. Perhaps together with some 3D printed cartilage.