A 40 year old woman in Singapore living with a congenital heart defect will have her heart 3D printed to aid her doctors with finding a safer and faster way to finally correct it. The heart model will be created from common CT scans and will allow the woman’s doctors to pre-plan the surgery. Pre-surgical planning enables them to complete the procedure much quicker, lessening the chances of complications and speeding up the recovery process.

As the 3D printing industry matures, applications only dreamed about are starting to become commonplace. Less than a year ago I sat in on a talk at the 3D Printer World Expo in Los Angeles while a well-respected doctor explained how 3D printing could help plan out surgeries before they started and detailed the extensive list of benefits of it. There had been a few cases at the time proving how valuable it was, but it was still incredibly rare. Not only due to the fact that most hospitals didn’t have access to 3D printing facilities, but CT scans are incredibly large files and converting them into 3D models was prohibitively expensive and time consuming.

But in that short span of time we’ve seen dozens of cases where 3D printing aided in surgeries and life-saving procedures. There are now several new types of software that can convert the large DICOM files into 3D models almost effortlessly. While the process is hardly commonplace, it’s common enough that it’s well on it’s way to being so. And in the case of the woman in Singapore it’s going to completely change her life.

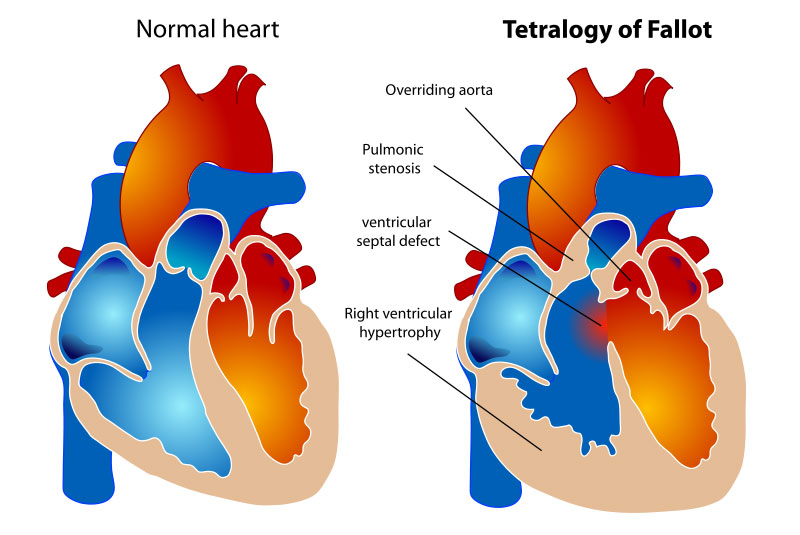

She suffers from a condition called Tetralogy of Fallot, a congenital heart defect comprised of four separate but distinct defects that ultimately result in a low level of oxygen in the blood. There have been palliative surgical procedures that could alleviate the symptoms since the 1940’s, but there was not a corrective surgery that was considered safe until the 1980’s. But the corrective procedure still requires full open heart surgery, and regardless of how far advanced we’ve become that is always highly dangerous. Especially if the patient is in poor health.

The patient is having the replica of her heart 3D printed by a local company called Creatz3d. The 3D printing company had Materialise convert the files into an STL format and segmented it for printing. The heart will then be 3D printed and delivered to the patients doctor for the pre-planning process. Complicated heart surgeries are always dangerous, and having a model of the affected heart will greatly increase the chances of the heart being repaired quickly and without complications.

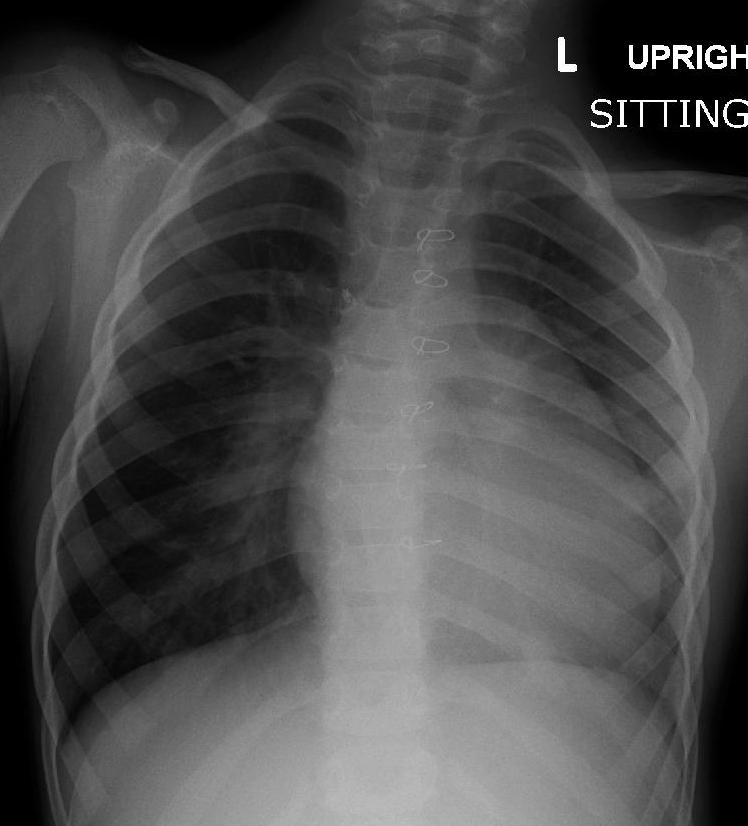

While CT or MRI scan data provides doctors with plenty of information about the defects, a lack of spacial dimensions makes it difficult to visualize what they will see when they open up the heart. This means surgeons need to open the chest, inspect the heart, locate the flaws and then plan out how to successfully correct them on the fly. Not only is the time required for this dangerous for the patient, but the longer a surgery takes the higher the risk of the surgeon becoming fatigued becomes.

Pre-surgical planning with the use of 3D printed models and surgical guides dramatically reduces the time required to perform the surgery. By allowing doctors to know exactly where the corrections need to be made, they don’t need to come up with a plan for repair on the fly. This leads to less time under anesthesia, reduces the amount of blood lost during the procedure, reduces the number of incisions that need to heal, lessons time spent in the hospital and encourages a faster recovery.

3D printing has been around for twenty five years now, but when it was invented it was simply treated as an industrial process. No one could have ever imagined some of the wonderful uses that would be found for the technology. But when the patents expired a few years ago and the maker community started to change the way that we looked at the process that all changed. While 3D printing is still an industrial process for the most part, it’s also evolved into something bigger. It’s been infused with the philosophy of the maker.

There are no limits any longer. If we can’t do something, it isn’t that it’s impossible, we just haven’t found the way to do it yet. In the space of a year, a woman went from believing that she would live the rest of her life with a condition that could potentially kill her to having that condition corrected almost with ease. Not bad for a single year, I can’t wait to see what we can do next year.