Ever since colorFabb signed its high profile partnership with Eastman Plastics, a giant that produces dozens of high-level polymers, especially copolyesters, the number of new, materials that the company is able to launch is limited only by the time necessary to test and produce them.

Now, the time has come for nGen, a filament based on Eastman’s Amphora AM3300 3D polymer, part of the Eastman Amphora range of copolyesters, developed specifically with 3D printing in mind. It is a low-odor, styrene-free material specifically targeted at new generation 3D printing enthusiasts, particularly those who need the flexibility to print within a wide processing temperature range.

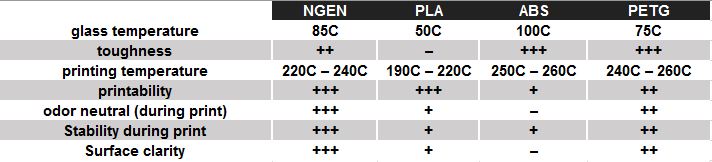

With a glass temperature of over 85ºC, nGen it has over double the heat resistance of PLA and, thus, offers superior mechanical properties without sacrificing exterior appearance or printability. In fact, colorFabb assures that the filament will have good flow properties through the printer nozzle, even at lower temperatures than some other polymers require.

One of nGen’s most interesting features is its melt stability, meaning that, from pellet to filament to 3D Printed part, the mechanical properties of the material will hardly be affected, providing a great deal of printing stability and highly optimized repeatability.

ColorFabb will initially release 17 varieties (including 16 colors and one clear filament) in both 1.75 and 2.85 diameters. Colors range from “whiter than white” to metallic silver and include light blue and royal purple.

The R&D team at colorFabb has been extensively testing its nGen on a wide range of popular 3D printers, including the LulzBot Mini (see video below), Ultimaker Original, Ultimaker 2, Mass Portal Pharaoh ED, Stacker, Makerbot Replicator 2, Deltatower, Prusa i3 Hephestos, and Leapfrog HS.

ColorFabb has gathered that nGen proved to be an excellent material during testing for a wide range of applications, including home appliances, consumer electronics, toys, visual and functional prototyping, modelling and character design, lighting and medical prosthetics.

It might very well open up a new era of adoption for desktop 3D printing and that is no surprise. ColorFabb knew from the beginning that the key to 3D printing is advanced materials availability.