As we had anticipated, CELLINK, the Swedish startup that has made headlines lately with its bioprinting consumable cartridges and the INKREDIBLE low-cost bioprinter, is partnering with RoosterBio, a producer of stem cells. Now, the terms of that partnership have become clearer, as the two companies will collaborate on producing and commercializing the industry’s first living cellular bioink kits.

“Innovation is no longer emerging from solo developments within one single organization,” CELLINK Co-Founder, Erik Gatenholm. “Modern innovation and the future of the medical industry is driven by collaborative efforts made by multiple players thinking outside the box. As biomaterial and Bioink experts we must therefore surround ourselves with other experts, such as RoosterBio, to complement and expand our product offerings and synchronize our efforts towards the ultimate vision: to one day reduce the shortage of supply in the organ donor market with 3D Bioprinting technologies. This revolutionary, cost effective, and elegantly simple-to-use Bioprinting Kit is exactly what innovators and early adopters worldwide need to propel their research in the tissue-engineering field. By offering a complete package of the right bioink together with the right cells we can finally establish the first standard in the bioprinting industry.”

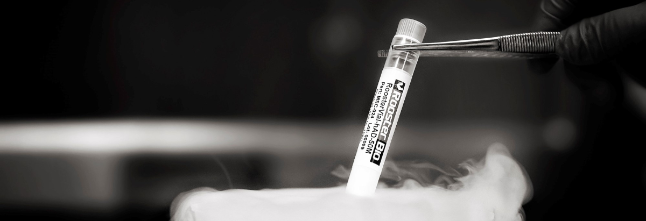

These kits combine RoosterBio’s industry-leading adult human mesenchymal stem cell (hMSC) systems and CELLINK’s universal bioinks with simple protocols for high-fidelity mixing and printing of living cellular constructs. These kits already have a number of possible uses: from creating human tissues for research, drug development and testing, to, ultimately, the replacement of tissues and organs for patients in critical need of a transplant.

Just as 3D printing is disrupting industrial manufacturing, 3D bioprinting is accelerating the field of bioengineering and biotechnology by enabling the digital manufacturing of these living cellular products with high fidelity and viability. And just as with 3D printing, 3D bioprinting also requires a diverse set of technical skills and infrastructure, including 3D printing hardware, CAD software, and – most importantly – feasible and standardized materials. In the case of bioprinting, this means cell-friendly biomaterials and the ability to generate large quantities of highly potent stem cells.

RoosterBio and CELLINK are collaborating to enable customers to begin bioprinting living cellular constructs immediately through the introduction of living Cellular Bioink Kits containing highly standardized hMSCs and polymeric hydrogels, in ready-to-use formats, that are suitable for a variety of technical applications. These products are designed for streamlining the cellular bioprinting workflow, thus accelerating the path to discovery, clinical translation and commercialization of tissue engineered constructs for organ repair and regeneration.

“It has long been appreciated that technological revolutions are driven by the availability of easy to use and inexpensive kits,” commented RoosterBio’s CEO, Jon Rowley. “RoosterBio’s partnership with CELLINK underscores this ethos and solves multiple challenges in the emerging bioprinting marketplace. Our combined technologies will help democratize tissue engineering and 3D bioprinting technology – enabling a much larger audience to gain access to know-how that has typically taken years to establish. We are very excited for our initial products, and future products to come.”

The Cellular Bioink Kits were unveiled at the Tissue Engineering and Regenerative Medicine International Society (TERMIS) World Congress in Boston, which saw a number of announcements, presentations and exhibitors in bioprinting. Now, the next appointment for those interested in this amazing new segment of additive manufacturing is the Biofabrication 2015 conference in Utrecht. 3DPI will be there.