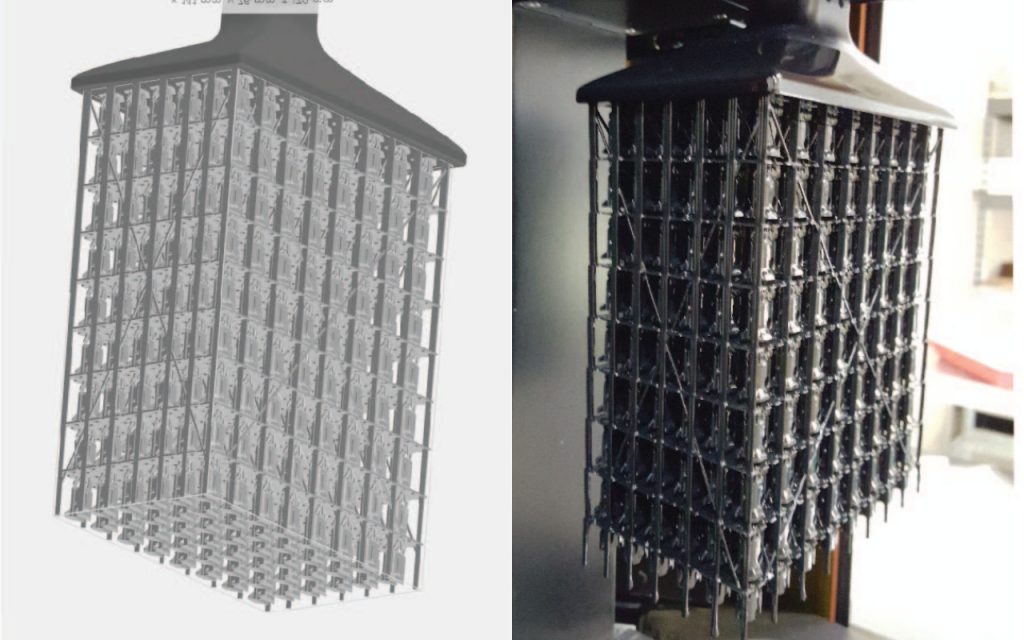

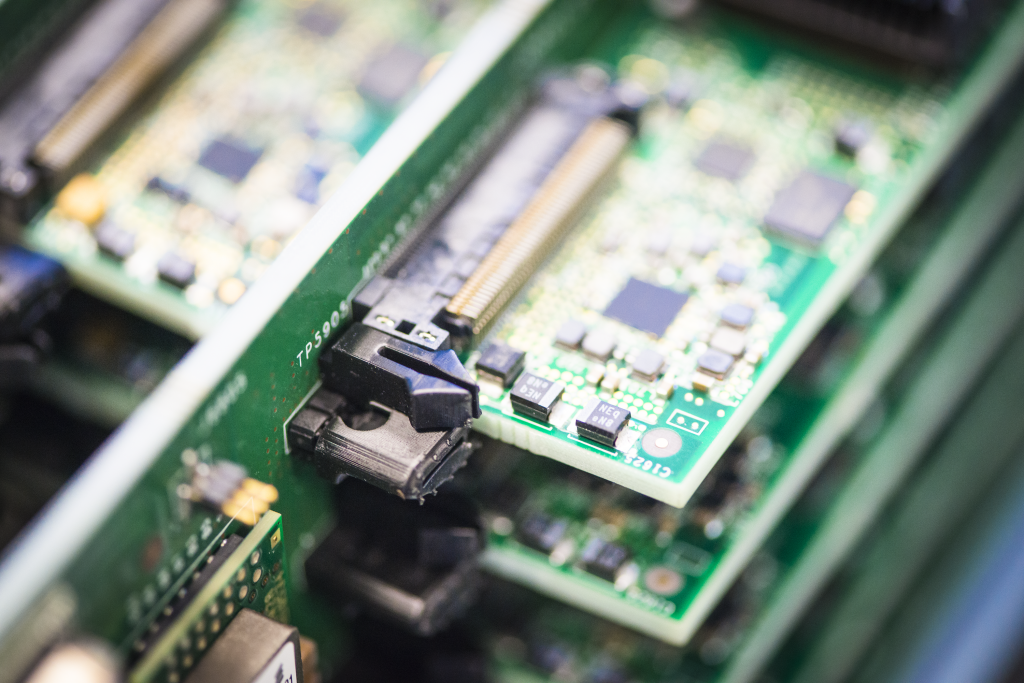

Oracle Labs, the research and development branch of multinational computer technology corporation Oracle (NYSE:ORCL), has used Carbon CLIP technology to 3D print a series of end-use brackets for use in its micro servers. 10,000 of the parts were needed to align circuit boards in the systems, and production was turned around within days instead of months.

Going beyond 3D printed prototypes

At first, Oracle planned on a component design reliant upon injection molding to hold the circuit boards. This method proved to be ineffective at producing such small parts within the required time frame, and the method didn’t support multiple design iterations. Speaking to Carbon in a case study of the project Craig Stephen, Senior Vice President Research & Development at Oracle Labs, explains,

Our R&D team had designs we needed to produce at scale. Working with Carbon extended our prototyping into production quantities and qualities. We received structural parts when we needed them and in volumes to get the job done.

Serial production in 3D printing

As previously reported on 3D Printing Industry, Carbon partnered with Oracle to integrate its cloud based services into its operational infrastructure. The company has also launched its SpeedCell system to streamline the workflow of industrial CLIP 3D printing.

To fully explore the variety of applications open to 3D printing technologies, other companies are also looking towards a means of enabling serial production. Premium AEROTEC, EOS and Daimler are working together toward such ends in the Next Generation Additive Manufacturing project. With a conveyor belt operated 3D printer BigRep and TNO researchers are looking at serial production and mass customization. 3D modeling software is also working to follow suit.

For more of the latest news on 3D printing for serial production sign up to the 3D Printing Industry newsletter, and follow our active social media sites.

Don’t forget to vote in the first annual 3D Printing Industry Awards.

Tickets for the 3D Printing Industry Awards are also now available here.

Featured image shows two of the ten thousand 3D printed Oracle server mounts. Photo via Carbon