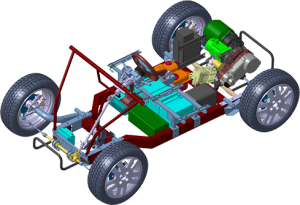

The goal is very ambitious: disrupt one of the capitalist world’s biggest industries and industrial growth providers. Last year OSVehicle set out on its mission to open up car manufacturing and development to all with its Tabby and Urban Tabby Projects. These are open source kits that make it possible to build a drivable car in less than one hour, choosing between combustion, electronic or hybrid propulsion systems.

For the OSVehicle team it was seen as an opportunity to truly delocalize and democratize car manufacturing, thus reducing costs, production times and environmental impact. Challenging the “Big Car,” makers however, is no easy task. Although technology is bringing about drastic, revolutionary and unstoppable changes in manufacturing, the process is not just going to happen overnight. 3D printing is going to play a big part in it, by making prototyping more affordable and accessible to smaller companies and even individuals.

That is why OSVehicle has recently introduced the possibility of downloading the Tabby as a 1:5 model. In other words it is now making it easier to prototype the cars for users to develop designs that could later be replicated on larger size models. At a 1:5 scale it is much more feasible to use 3D printing to build the outer parts of the car. By introducing open source electronic kits it would even be possible to turn the prototype into an OS RC 3D printed car.

Compared with the other popular open source/co-creative car project Local Motors, which focuses on collaborative prototyping with a specific focus on 3D printing, OSVehicle, as the name implies, was initially more focused on the open source aspect of the basic mechanical kit for its Tabby model, which, in a way, is similar to an open source 3D printer kit, meaning you can source and 3D print the parts yourself, or you can purchase the pre-sourced kit from OSVehicle and focus on its development and evolution.

“Our primary goal is to enable people to build the vehicle in the location where it will be sold and used – he told me – we are currently speaking with investors to start with full industrial production of our kit. Our goal is to create a community of small entrepreneurs, engineers, mechanics and makers who will collaborate on developing this project. Even in Italy years ago there were hundreds of small factories that produced small series of cars, then they were all replaced by the car manufacturing giants. It would be great to once again empower single people to build their own cars,” Carlo told me.

This is made possible by implementing an open source business model, which drastically reduces the costs for research & development each individual would have to undertake. 3D printing technologies will definitely come in handy to work on the scale models and on the smaller components and who knows, in the future even for the delocalized production of the final, functional Tabbys.