Eliud Kipchoge, the world’s fastest marathon runner, is hoping to win the 2018 London Marathon this Sunday, April 22, wearing 3D printed “Flyprint” shoes from Nike, inc.. Kipchoge, wearing Nike running shoes, has previously come tantalizingly close to running a marathon in less than two hours, with a time of 2:00:25, the fastest marathon ever run.

The shoe’s upper portion is entirely 3D printed. “We’ve been using 3D printing for a variety of things at Nike for around a decade, but most heavily in prototyping. This is the first upper that will be more mass applicable,” said Nike senior director for global running footwear, Bret Schoolmeester speaking to WIRED.

Shoes for record-breakers, in 30 minutes

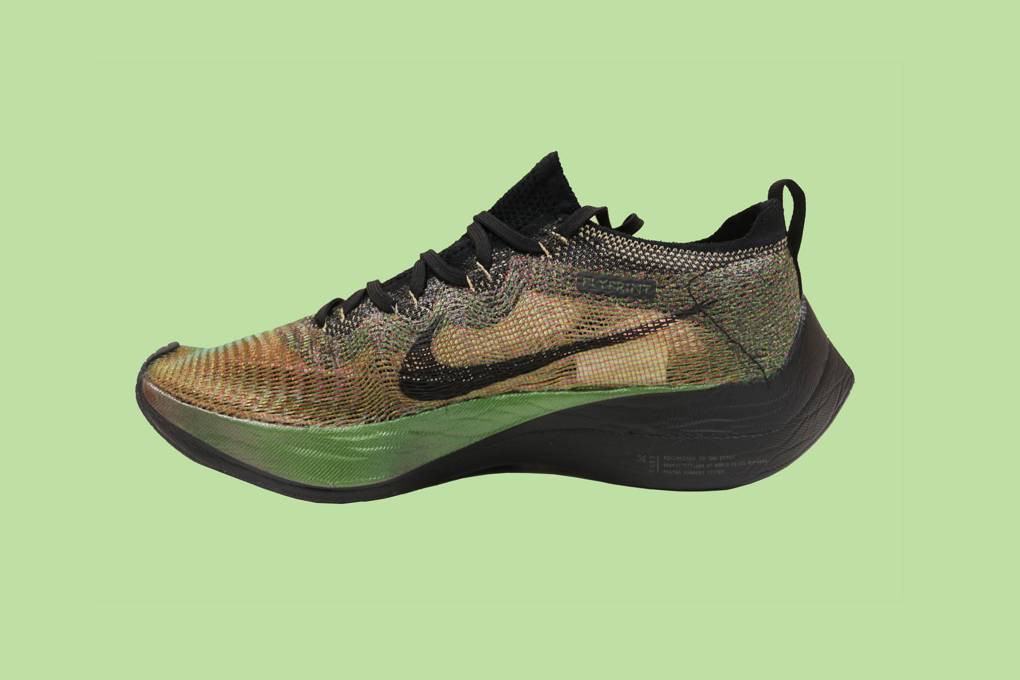

The top portion of the shoes are made from 3D printed threads of polyurethane that Nike calls “Flyprint” fabric. Each thread, printed with solid deposit modeling, is less than a millimeter thick and spans the entire length of the shoe.

Roger Cheng, a 3D printing specialist working at Nike says that the shoes can be printed in 30 minutes with precise control over the positioning of threads “We can get down into the specific thread level and control everything: length, curvature, diameter.”

Customised shoes for elite runners

Nike has developed other pairs of 3D printed shoes for elite long-distance runners, each personalized, and six percent, approximately 11 grams, lighter than Nike’s previous shoe designed for marathon runners, the Zoom Vaporfly Elite.

Working with Kipchoge, Nike’s designers implemented the wave pattern on the trainers that you can see below. Using pressure data and 3D scans of Kipchoge’s foot, the waves are specifically formed to the runner’s feet, allowing for a greater degree of movement. Nike was able to apply the modifications, print, assemble and ship the shoes from the U.S. to Kenya, where Kipchoge resides, within nine days.

Limited numbers of the Flyprint shoes will be available before the London Marathon, priced at £499.

“I can go in and manipulate every single thread and how it is going through the entire upper. The level of the precision that a designer has now is amazing” said Cheng.

3D printed footwear contenders

Reebok has released a shoe with 3D printed “laces”, the Liquid Floatride Run shoes. The production process uses “3D drawing” technology, where a single layer of material is deposited, which dried to form the shoe’s laces.

The shoe store ECCO is offering in-store 3D scans for custom 3D printed insoles in their Amsterdam concept store.

Next season, players from 32 NFL teams will receive custom 3D printed cleat shoes from HP. The shoes will be 3D printed using 3D scans and body data from players.

For the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Advance your career in 3D Printing, or post a vacancy. The 3D Printing Jobs board is live.

Vote in the 2018 3D Printing Industry Awards before it closes.

Featured image shows Eliud Kipchoge’s attempt at running a marathon in less than two hours. Photo via The Drum.