A European Union (EU) funded project, BARBARA (Biopolymers with Advanced functionalities foR Building and Automotive parts processed through Additive Manufacturing), has concluded four years of research into producing bio-based materials suitable for 3D printing prototypes in the automotive and construction sectors.

Included within the EU’s Horizon 2020 framework, BARBARA brought together 11 partners from Spain, Italy, Germany, Sweden, and Belgium, to develop the new 3D printable materials from food waste and agricultural by-products.

Aims of the project

Environmental and social concerns about the amount of food being thrown away and going to waste in the developed world have been steadily growing over the past decade. In fact, the EU alone produces around 110 million tonnes of food waste each year.

Four years ago, and armed with a €2.7 million budget, participants in the BARBARA project set out to find ways to reuse bio-waste for the production of bio-plastics with added-value industrial uses. The aim of the initiative was to use the newly-created bio-based materials to form concept prototypes, manufactured using a Fused Filament Fabrication (FFF) 3D printing process.

The project required the new materials to be based on food waste, such as vegetables, fruits, and nuts, or agricultural by-products such as corn. The materials also needed to have specific mechanical, thermal, and antimicrobial properties to be suitable for industrial use in components within the automotive and construction sectors.

The automotive sector was chosen for this project due to its often tailor-made approach to vehicle components, shape, and design, requiring a high degree of flexibility and innovation capabilities. Meanwhile, the construction sector was selected for its unique characteristics and requirements, involving parts that often need to be custom-made.

Project outcomes

During the course of the project, a total of eight new bio-based materials were successfully developed. The materials underwent high temperatures, water cooling treatments, and material binding and reinforcing to create filament spools suitable for the FFF process.

The materials contained polyester and polyamide polymers mixed with polysaccharides derived from corn and additives from pomegranate, lemon pigment and scent, and almond shell. Each of these additions gave the materials different textures, colors, and fragrances, as well as antimicrobial and antioxidant properties.

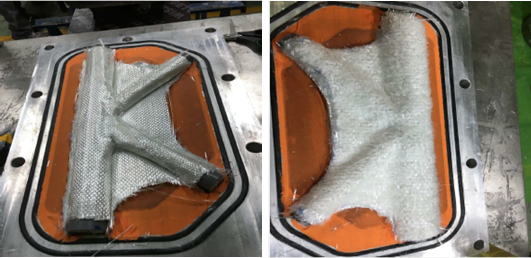

The teams produced demonstration prototypes such as car door trims, door handles, and dashboard fascias for the use in the automotive sector, and molds and tools for the creation of knots for beam trusses in the construction sector.

Reportedly, the next step for the project is to scale up the work that has been carried out so far to take the prototypes from the lab to a semi-industrial level.

3D printing biomaterials from food waste

Additive manufacturing of food waste is not a necessarily new phenomenon, in fact, 3D printing firms have been developing biomaterials from waste food and other matter for years. However, in an era where pressure is increasingly mounting over the sheer amount of food for human consumption that is wasted or lost each year (roughly 1.3 billion tonnes globally), this is an area that is being tapped into by those in the 3D printing sector more and more.

Back in 2015, Italian designer Marina Ceccolini began creating her own potential 3D printing material called AgriDust, inspired by dehydrated tangerine peel. Held together with potato starch, AgriDust was created from all manner of foods found in Ceccolini’s local landfill, including coffee grounds, peanut shells, orange and lemon peels, tomato skins, and bean pods.

Elsewhere, The Digital Matter Intelligent Construction Research Studio at the Institute of Advanced Architecture of Catalonia introduced a new type of bioplastic with the potential to replace traditional petroleum-based PET plastic, while student-founded start-up company Genecis combined biotechnology, machine learning, and microbial engineering to convert food waste into PHAs, a fully biodegradable form of plastic.

In a slightly different approach, Netherlands-based start-up Upprinting Food takes bread, fruit, and vegetables which have been thrown out due to being too ugly or ripe to be sold, but instead of turning the food waste into a bioplastic material, the firm blends together the different ingredients to create edible 3D printed snacks.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the BARBARA project has concluded four years of research into producing bio-based materials suitable for 3D printing prototypes. Image via BARBARA project.