In a heartwarming display of charity, Autodesk, Enable Community Foundation (ECF) and Voodoo Manufacturing, have partnered up to bring us the world’s first global hand-drive for manufacturing and assembling 3D-printed prosthesis. The drive comes out of Autodesk’s Global Month of Impact, which calls for 28 offices from around the world to put together 750 prosthetic hands for children in need of upper-limb prosthetics.

Team work makes the dream work

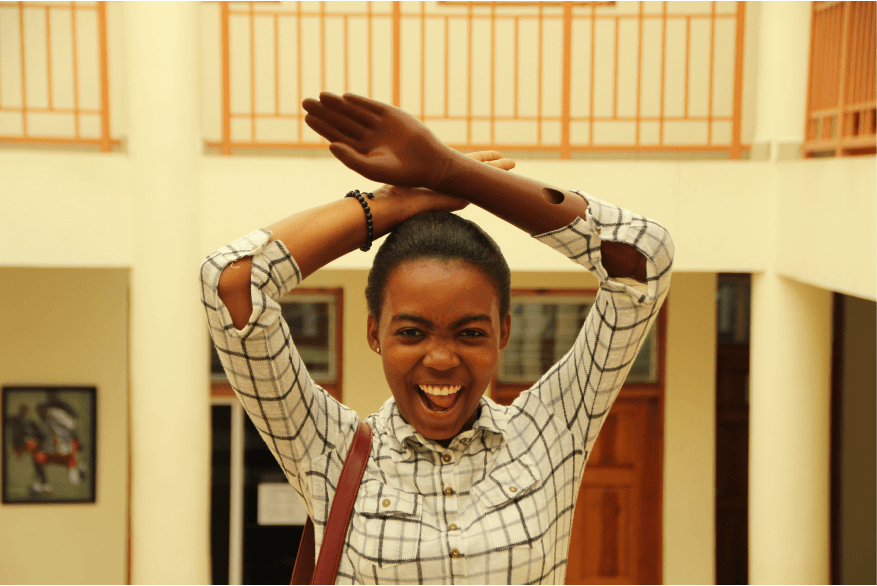

As an Autodesk Foundation grantee, ECF has been dedicated to creating low-cost prothesis for those in need. As a result, they have already provided nearly 1,400 prosthetic hands and are continually expanding upon that number. Together with Voodoo Manufacturing – a digital 3D printing factory based in Brooklyn – they’ve printed 22,500 parts that make up the 750 prosthetic hands. Amazingly, each hand took about 10 hours to print and in total, Autodesk’s team put in 6,000 combined volunteer hours.

Tackling the big problems

According to the Autodesk team, the prosthetics industry previously faced several large problems:

“In the United States alone, close to 200,000 amputations are performed each year and each prosthetic costs thousands of dollars. Traditionally, the process of getting a prosthetic limb can take anywhere from several weeks to months, and since prosthetics are such personal items, each one has to be custom made or fit to the needs of the individual, and children can quickly outgrow a device.”

To combat this, the three partners have banded together for this drive. As an onslaught of innovative 3D printed prothesis emerge for the 2016 Paralympics, Autodesk, ECF and Voodoo Manufacturing aren’t forgetting about the little guys who aren’t just yet prepared for professional games. Fortunately, however, they’ll be well on their way thanks to this latest donation.