Global standards developer ASTM International has announced its first round of funding to support the development of standards for the additive manufacturing industry.

NASA, the UK’s Manufacturing Technology Center (MTC), EWI, Auburn University and the National Institute for Aviation Research (NIAR) at Wichita State University will all benefit from the fund, with each body responsible for a different focus area.

Additive manufacturing standards

The development of appropriate standards is a key driver for industry-wide adoption of additive manufacturing. ASTM’s history with the technology formally dates back to 2009, when the organization established the F42 Committee on Additive Manufacturing Technologies. In 2016, the International Standards Organization (ISO) joined ASTM in its efforts and, this year, the organization published guidelines for powder bed fusion (PBF) technology.

Reinforcing its commitment to the industry, in August 2018, ASTM launched the Additive Manufacturing Center of Excellence program. This first round of funding, an investment of $300,000 and in-kind contributions, has been contributed to help members of the excellence program with ongoing research projects.

Materials, process qualification, post-processing, and testing

The MTC, which has been developing a skills competency framework for additive manufacturing throughout this year, will use the ASTM grant to develop standards for feedstock-characterization. Focusing on metal powders, the center will produce a guide to help evaluate quality and recyclability.

At NASA, researchers will develop standards and requirements to help qualify laser-PBF machines and processes.

North American engineering and technology organization EWI will be taking care of post-processing. Studying surface finishing techniques and the impact performance of 3D printed components this project will, according to ASTM, “will help standardize surface quality and measurement metrics.”

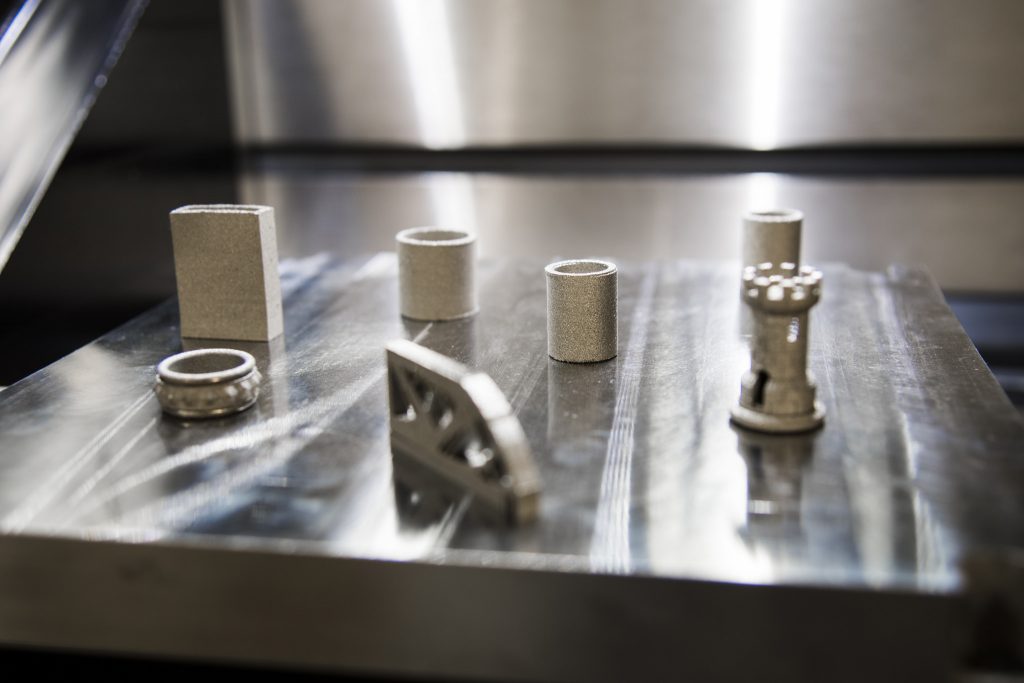

Auburn University‘s Additive Manufacturing Center of Excellence, within the Samuel Ginn College of Engineering in Alabama, is responsible for researching mechanical testing issues in metal 3D printing. One of the outcomes of this project is to create guidance for designing test coupons that “are most representative of additively-manufactured components.”

And finally, strategic partner NIAR will investigate mechanical testing issues of polymers.

Driving standards from Singapore

ASTM announced the grant and beneficiary projects at the F42 Committee meeting on 18th September 2018. The meeting was held in conjunction the Singapore Standards Council, the Singapore Manufacturing Federation, Standards Development Organization, and Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC).

Matthew Donovan, principal engineer and Swiss technology company Oerlikon and chair of ASTM International’s additive manufacturing research and innovation group, comments:

“We are very fortunate to work with such renowned organizations to leverage their expertise towards standardization in additive manufacturing.”

For 3D printing research updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking the next step in your career? Sign up to 3D Printing Jobs here.

Featured image shows a metal 3D printed sample component. Photo via Auburn University