With the goal of, one day, 3D printing sustainable homes for those in need, WASP has positioned themselves as pioneers in the process of ceramic 3D printing. And, though their Big Delta 3D printer will be the primary tool for producing these homes, the Italian company has also made smaller clay extruders available for desktop 3D printer owners. To demonstrate the potential and limitations of what they call LDM (Liquid Deposition Modeling), WASP teamed up with artist Francesco Pacelli.

Pacelli has become familiar with LDM through his work as an academic researcher at Politecnico di Milano’s 3D printing lab, LAB+. Due to the use of wet materials, LDM is limited in terms of geometries and may collapse, dry, and shrink during or after the printing process. For that reason, the material may be key to the technology and Pacelli has begun working with WASP to both widen the types of ceramics that can be printed, as well as determining the proper mixture and printing parameters for LDM.

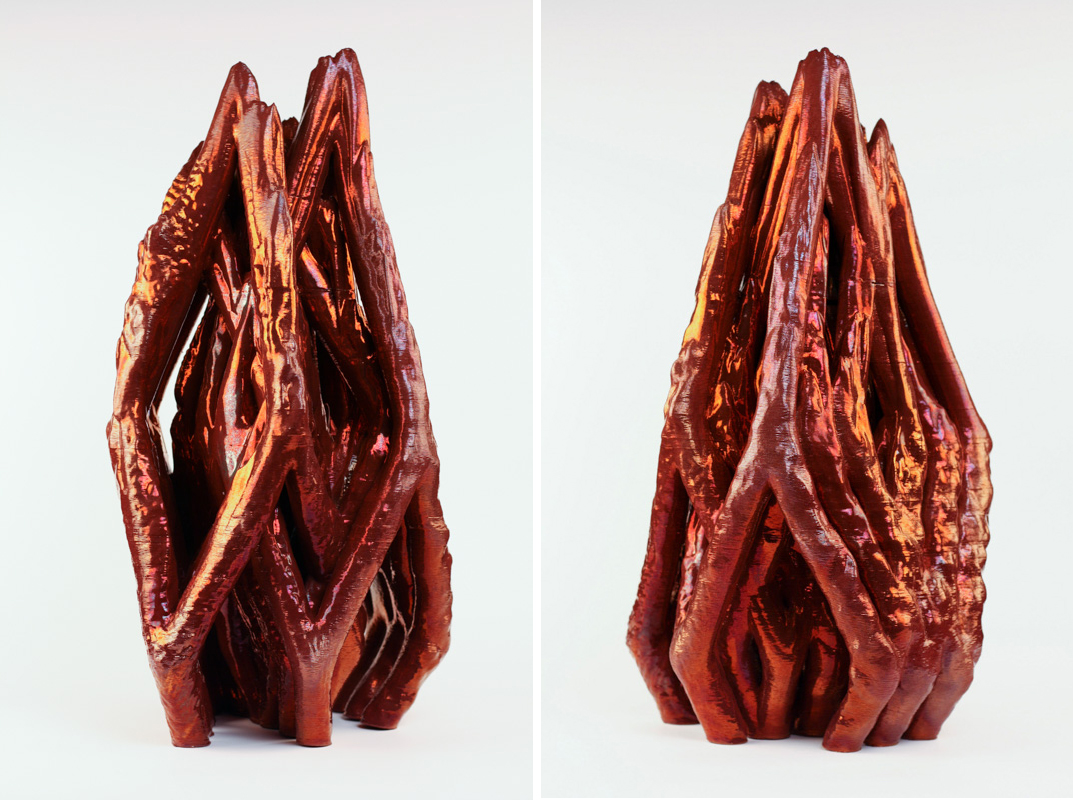

On his site, you’ll find a number of 3D printed objects created with this process. One important component to the technology’s success is a smart LDM extruder, developed by WASP, that uses a compressed air tank to feed the material to an endless screw, which maintains strict control over the flow process. But Pacelli outlines the specific parameters necessary to achieving a successful print, as well as the settings for a successful end product.

For instance, in the printing of a Limoges porcelain sculpture, the artist explains that the biscuit should be fired at 980°C and the glazed object fired at 1250°C. In another experiment, he recommends the use of plastic bags to cover extruded portions, in order to maintain humidity around maiolica clay and prevent cracking or delamination.

This is only the beginning for the partnership between Pacelli and WASP, as the artist will continue to research the proper process for LDM. And, while the artist uses WASP’s own LDM extruder, much of what he explores will surely be applicable to other viscous extrusion setups, as well. Though Pacelli has begun by demonstrating the use of LDM in creating sculptures, WASP acknowledges the potential of liquid 3D printing for a number of applications in engineering, fashion, and the biomedical field. The partners promise important updates in the upcoming weeks, including collaborations with ceramists in Faenza, an Italian city known for its ceramics.