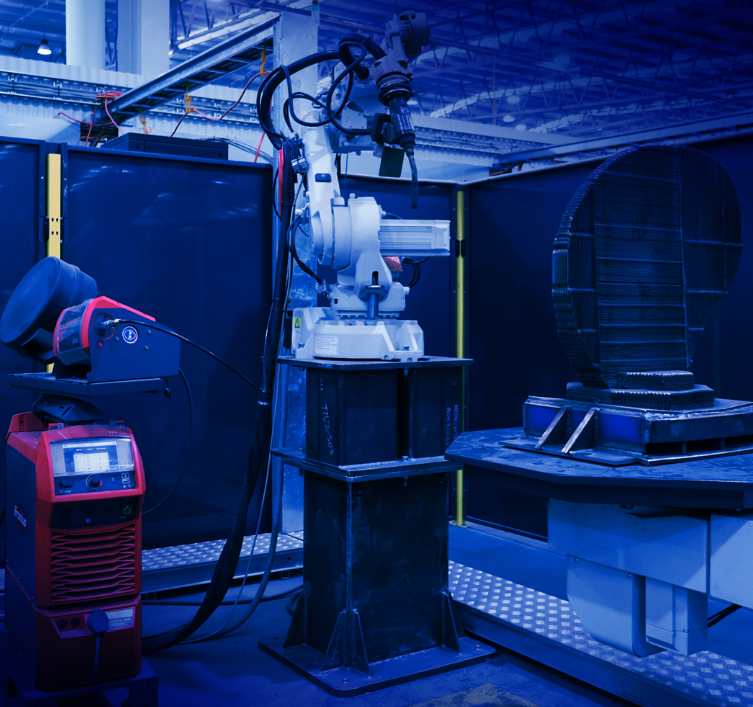

A large-scale ARCEMY ‘X-Edition 6700’ 3D printer from AML3D has been commissioned and is now fully operational at the US Navy’s Additive Manufacturing Center of Excellence (AM CoE) in Danville, Virginia.

Worth AUD$1.1 million, the Wire Arc Additive Manufacturing (WAAM) system adds to the Australian 3D printer manufacturer’s US ‘Scale-Up’ strategy, which delivered over AUD$12 million in orders last year.

This initiative seeks to address supply chain challenges within the US Department of Defense (DoD), especially the US Navy’s submarine industrial base.

This latest order was placed through Phillips Corporation, a reseller of AML3D technology. The payments of this deal were made in stages, corresponding to installation and delivery milestones. The successful commissioning of the 3D printer at the AM CoE has now triggered the final payment, worth 50% of the total order value.

“We are extremely pleased to have a fully operational ARCEMY ‘X’, our largest industrial metal 3D printing system, at the US Navy’s Danville Center of Excellence,” commented AML3D CEO Sean Ebert.

“The successful commissioning of this system is a clear demonstration of the effectiveness of our US ‘Scale-up’ strategy, the benefits of having Phillips Corporation as a reseller partner to complement our US sales force, and very much supports exploring opportunities to establish US facilities.”

AML3D securing the US Navy’s supply chain

Amid global geopolitical insecurities and attacks on shipping, the US DoD is actively adopting additive manufacturing technology to establish resilient, competitive, and sustainable domestic supply chains.

Through its ‘Scale-Up’ strategy, AML3D is working to become a point of need, additive manufacturing solution to support the US Navy’s industrial base. The company is confident that it will continue to pursue deals with the US DoD and supply more of its WAAM 3D printing technology in the future.

“The US Navy’s decision to install an ARCEMY X system at Danville demonstrates their confidence in AML3D’s advanced manufacturing technology and its ability to support the US Navy’s submarine industrial base,” added Ebert. “It is also a validation of AML3D’s strategic focus on delivering ARCEMY systems to the US maritime, federal and defense sectors.”

The past year has seen AML3D deliver several contracts to the US military. In November 2023 alone, the company received orders worth close to AUD$5 million from US Defense contractors Cogitic Corporation and Austal USA. Cogitic’s $2.5 million order outlines the delivery of ARCEMY metal 3D printed parts for US Navy submarines. Through the Austel USA order, worth $2.2 million, an ARCEMY WAAM 3D printer was installed at the company’s Virginia-based Advanced Manufacturing Centre.

2023 also saw AML3D announce an AUD$0.6 million prototype Nickel-Aluminium-Bronze (NAB) component order to support the US Navy’s submarine program. Here, a prototype part weighing around 1 tonne was 3D printed using an ARCEMY system over the space of 22-24 weeks.

Elsewhere, an ‘X-Edition 6700’ 3D printer was installed at the US Department of Energy’s Oak Ridge National Laboratory in February 2023. This large-scale WAAM system was acquired to assist the acceleration of advanced manufacturing techniques throughout the US defense industrial base.

Metal 3D printing adopted by US Navy

AML3D is not the only 3D printer manufacturer the US Navy has collaborated with to secure its supply of critical parts.

Earlier this month, it was announced that rocket engine manufacturer Ursa Major has signed a contract with the US Navy to design, 3D print and test a prototype solid rocket motor (SRM) for the Standard Missile (SM) program.

This collaboration will see the company leverage its Lynx metal 3D printing system to design and produce the next generation of SRMs which will power the SM-2, SM-3, and SM-6 missiles. Through the deal, it is hoped that 3D printing will scale up the production of these key missile components on US soil, addressing the high demand for SRMs.

2024 has also seen Velo3D’s fully integrated metal 3D printing system selected to support the US Naval Nuclear Propulsion Program. Incorporating the company’s Sapphire XC large format printer calibrated for stainless steel 415, this system will be operated as part of a Bechtel Plant Machinery Inc. (BPMI) contract. By leveraging Velo3D’s metal 3D printing technology, BPMI and materials company ATI hope to improve the part production process for the US Navy program.

Elsewhere, last year saw the US Navy install its first Phillips Corporation Additive Hybrid metal 3D printing solution on board one of its ships, the USS Bataan. This system incorporates a metal deposition head from metal 3D printer developer Meltio. Permanently implementing metal 3D printing capabilities on the ship has increased self-sufficiency and reduced supply-chain timeframes.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the ARCEMY ‘X-Edition 6700’ WAAM 3D printer by AML3D. Photo via AML3D.