Issues and Challenges in R&D

In my previous article I introduced the novel Voxel method of 3D printing, which is still very much in its infancy. As a result, the embryonic work in this area faces challenges that must be overcome and here in Part II in this series I aim to outline some of the specific obstacles we are facing to take this process to the next level.

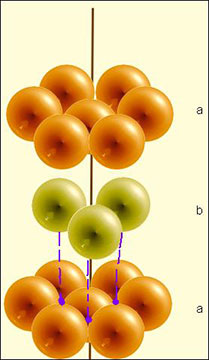

By far the biggest challenge with printing voxels (as opposed to layers) is alignment. It is important to remember that Voxels come in different shapes but are of repeatable nature. The easiest shapes to align are spheres, but even here it’s not as straightforward as it seems at first. Furthermore, when it comes to more complex shaped voxels, such as diamonds or triangles, alignment issues can drastically reduce the speed of printing, negating one of the primary advantages the process offers.

For voxel 3D Printing, one of the experimental ways to control alignment is to charge the voxels with an electrostatic charge, while the build table is charged with an opposite charge. Simple solution? Not quite. After the first layer of a part has been built with the charged voxels, the electrostatic charge from the build table has to now shift to the first layer of voxels. This means that the voxels have to reverse their polarity, which can subsequently cause nonalignment between the voxels that have already been deposited. From this it can be seen that the voxel spheres, which we considered as the simplest voxel shape, are themselves not so easy to be aligned. And what about the ‘marbles in a jar’ solution? Shaking the voxels so that they align themselves? It would be disastrous here because in 3D Printing, the accuracy depends more on how firm the build table is and vibrations — as many will attest — are a problem. If the build table doesn’t come back to its precise location after every ‘shake’ then we are adding another layer of complexity to the alignment problem.

Let’s look at another type of voxel – pyramids. Common .STL files already bring out digital designs in triangles. These triangles can act as the guiding rule for voxel alignment of pyramids but because these files don’t have standard units or scale information, it throws up further challenges. A simple precursor rule can be that the entire digital design should be created with a predefined scale that matches the physical voxel size that will be used for printing. But unlike spheres, packing the pyramids is a challenge. Spheres have a tendency to hug each other – they sort of cuddle up. Pyramids like their own space. Electrostatic alignment is a challenge due to flux effects. More so if the voxels are hollow.

It’s fair to say that there is no easy solution but investigations continue.

Prototypes of voxel 3DP machines have been made in the past and are continuing to be researched. So far they are being termed as ‘rapid assemblers’ rather than printers. Binding of voxels is based on water-soluble glues so that supporting voxels (like support material) can be selectively removed later on. One technology that is being explored is similar to laser jet printers where a complete layer of voxels is deposited at once. In this case, each layer is first assembled separately before being lifted and placed on another layer. These developments are as intriguing as they are potentially ground-breaking, because successful outcomes of the research into voxel 3D printing would be the sure shot way of building embedded sensors into functional components.