Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

Is 3D printing sustainable? Not everyone agrees.

3D Printing Industry visited AM Summit 2023, Scandinavia’s largest additive manufacturing conference, to hear from additive manufacturing industry experts on core topics – including sustainability and 3D printing.

The Copenhagen-based event saw debate surrounding what sustainability means in additive manufacturing, and whether 3D printing is actually sustainable at all.

“I’ve heard so much sustainable this and that here, and nobody has a clue whether it’s actually sustainable or just more sustainable than something else, and this is exactly the problem” argued Michael Hauschild (PhD), Head of DTU Centre for Absolute Sustainability.

This year’s event hosted a range of panel discussions. Of particular interest was an evaluation of Danish AM Hub’s new CO2e carbon emissions calculator, and insights into digital distributed manufacturing.

Read more insights from AM Summit Denmark 2023

Danish AM Hub’s CO2e calculator

During AM Summit 2023, Marie Langer, CEO of 3D printer manufacturer EOS, highlighted the benefits of the company’s 3D printing Cost and Carbon Calculator. However, EOS is not the only organization to develop a CO2 calculator for the additive manufacturing process.

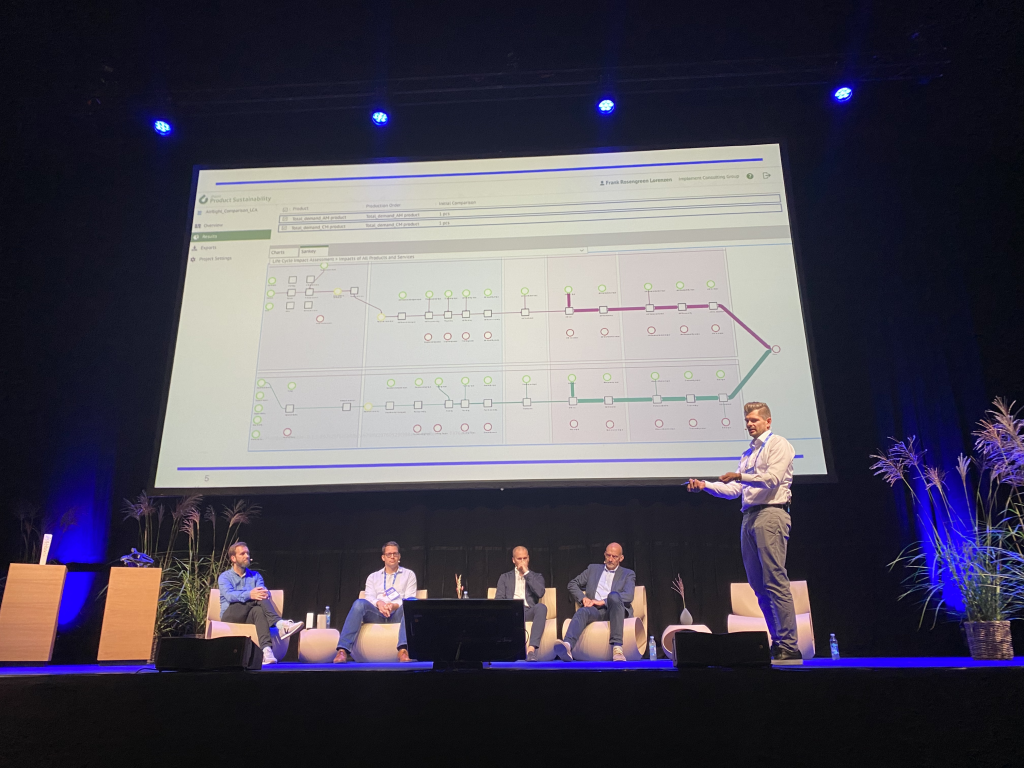

Danish AM Hub has developed its own tool, the CO2e calculator. This seeks to visualize the sustainability benefits of 3D printing compared to traditional manufacturing methods.

During this year’s conference, a panel discussed the utility of the tool, highlighting a number of case studies showing the CO2e calculator in action. The discussion also outlined the challenges associated with accurately defining and calculating sustainability in additive manufacturing.

“It’s a really groundbreaking initiative for us,” commented AM Hub CEO Frank Rosengreen Lorenzen.

According to Lorenzen, a key aim of this tool is to turn the discussion around in manufacturing. “Manufacturing is all about efficiency and it’s all about time. Why not also talk about sustainability?” Danish AM Hub also wanted to create a tool that conducts CO2 calculations before the manufacturing stage “because the planet doesn’t care about a life cycle analysis (LCA) if we don’t use it to change our behavior.”

The CO2e calculator itself is “really simple,” stated Lorenzo. Comparing a traditional manufacturing process, such as milling, with a 3D printing process, the calculator outputs one number – Highlighting the amount CO2 saved or gained by using additive manufacturing.

The CO2e calculator was Developed in collaboration with the Copenhagen-based Implement Consulting Group. Jan-Markus Rödger, Sustainability Strategy Partner at the group, explained that the tool assesses all phases of a products life cycle, “starting from the raw material, to the processing, to the transportation, to the actual product, the use phase and the end of life.”

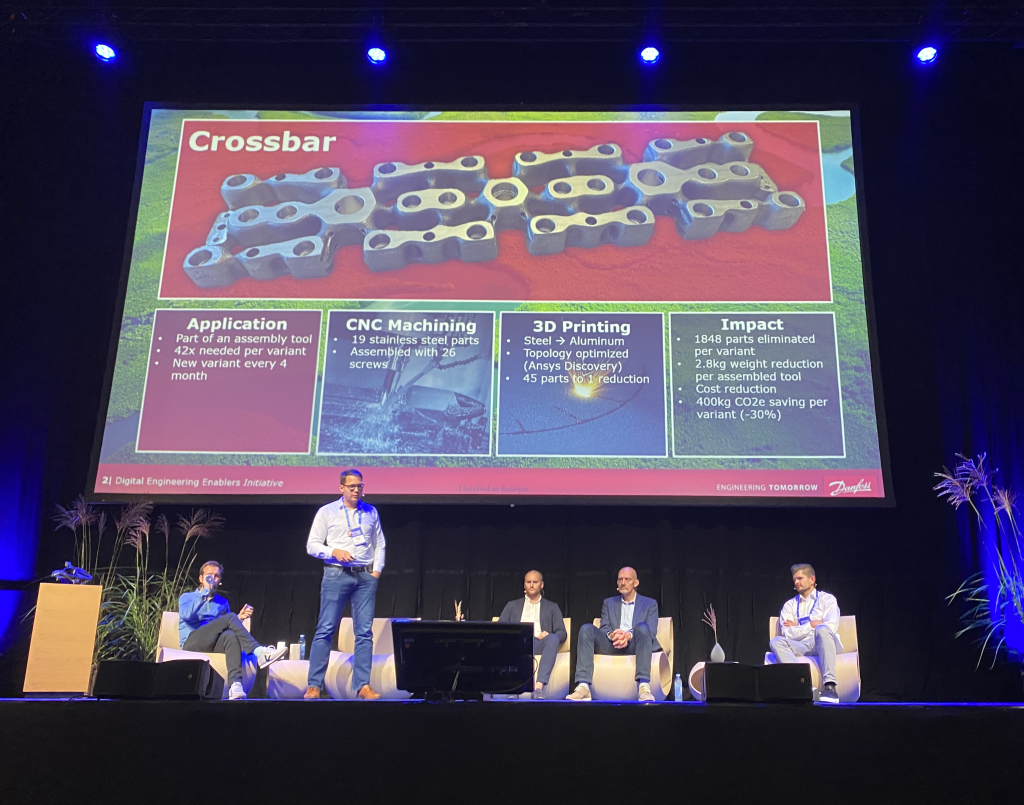

One use case of the calculator was outlined by Niklas Franke, Head of AM and Production Simulation at Danfoss. This Denmark-based manufacturer has a wide product portfolio which includes compressors, pumps, and heat exchangers. “The common theme is really that these products use energy, and we can create value for our customers by reducing this energy,” explained Franke.

As part of its mission to reduce energy and improve sustainability in production, Danfoss conducted a CO2 calculation on a metal crossbar component using Danish AM Hub’s tool. This component is part of an assembly tool in one of Danfoss’s factories. Franke explained that 42 of these tools are needed for a product variant, with a new variant needed approximately every four months.

Previously CNC machined out of steel, the company now 3D prints the part. According to Franke, 3D printing has allowed Danfoss to use aluminum rather than steel, and consolidate the number of manufactured parts from 45 to just one. As a result, the company has eliminated 1848 parts per variant, with a 2.8kg weight reduction per assembled tool.

The CO2e calculator helped Danfoss determine whether the additive manufacturing process is more sustainable than the CNC alternative. “In this case, we can say yes, it is 30% more sustainable because we save 400kg of CO2 per variant,” explained Franke.

The CO2e calculator was also employed by hypercar manufacturer Zenvo Automotive A/S. The Danish company used the tool to determine the sustainability of its 3D printed suspension upright components for its TSR-S sports cars. According to Alberto Solera, Technical Director – TS Series at the company, the CO2e calculator broke new ground. Zenvo has “never really looked at the environmental impact until now with the calculator that you guys have provided.”

Danish AM Hub’s tool highlighted the weight savings offered by additive manufacturing. The SLS 3D printed parts save 800 grams compared to those produced with sand casting techniques.

“There’s four of these on each vehicle. So in our world, that is worth a substantial amount of money,” explained Solera. The CO2e calculator also highlighted additive manufacturing as reducing carbon emissions by 225% compared to the conventional method.

Calculating absolute sustainability in AM

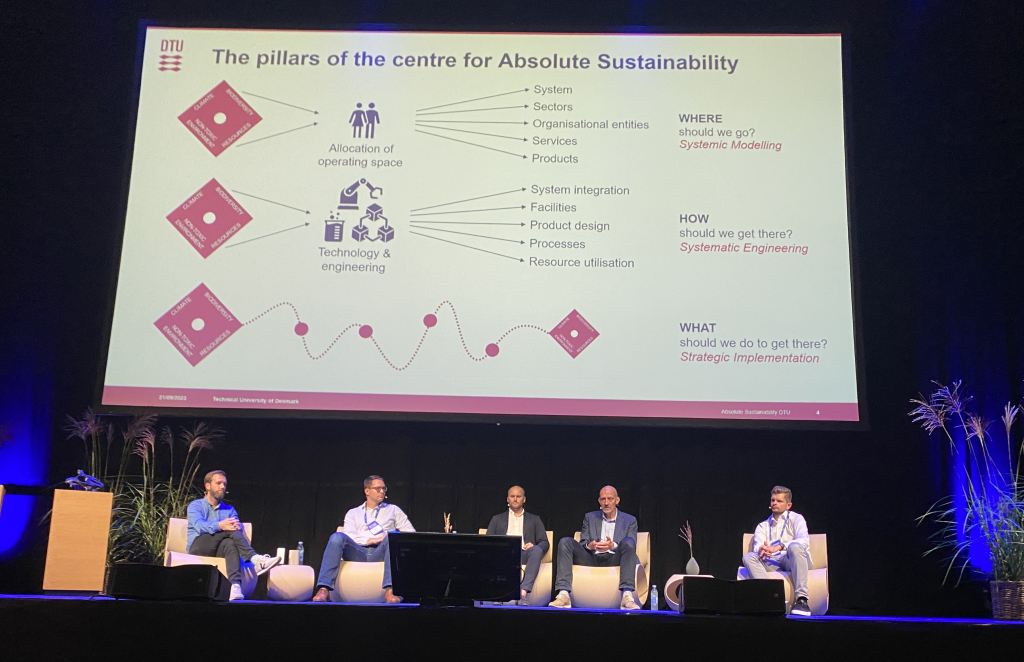

Whilst the benefits of 3D printing over conventional manufacturing can be clearly displayed with the calculator, Hauschild believes that the conversation around sustainability requires more clarity.

Whilst acknowledging the value of LCA’s for comparing 3D printing to alternative manufacturing methods, Hauschild’s focus at the DTU Centre for Absolute Sustainability revolves around whether “something is sustainable in absolute terms.”

According to Hauschild, a key limitation of the CO2e calculator is that it only indicates if one method is more sustainable than another, and “doesn’t tell us whether it’s sustainable.”

But how can absolute sustainability be measured in additive manufacturing? According to Hauschild, this can be achieved by framing the environmental impact of 3D printing within “biophysical boundaries.” For instance, the targets outlined by The Paris Agreement are highlighted as “absolute requirements” for sustainability.

These requirements include limiting global warming to 1.5℃ above pre-industrial levels, greenhouse gas emissions peaking by 2025, and achieving carbon neutrality by 2050. Therefore, Hauschild believes that the sustainability of additive manufacturing should be measured against specific benchmarks such as these.

“If we want to talk about whether AM is sustainable in absolute terms, we need to see the way we use it, and whether it will enable us to meet the needs within these biophysical boundaries,” added Hauschild.

Hauschild also highlighted data quality as being one of the biggest challenges when it comes to conducting LCA’s and assessing sustainability.

“It’s really important to get the data right where it matters,” explained Hauschild. “If your processes or the specific material you are using are really driving the impact, then you need to look into how good the data actually is. If it’s not good enough, then you need to invest time to get better data.”

Decentralizing supply chains through Distributed Digital Manufacturing

Securing supply chains and decentralizing spare part production is currently a big theme within the 3D printing industry. Indeed, questions surrounding the future of 3D printing in the supply chain gained a lot of attention earlier this year at AM Forum in Berlin.

During AM Summit, a panel discussion highlighted how digital distributed manufacturing (DDM) can be used to create more resilient and sustainable decentralized supply chains.

“25% of Danish industry has adopted AM to some degree today. But what we hear when we talk to small and medium-sized businesses is that this is typically within the product changes category. We don’t see as much when we talk about the value chain within AM” explained Amalie Kaysen, Head of Product and Portfolio at Danish AM Hub. Kaysen noted that “there’s a big potential in looking at the value chain piece,” with DDM seen as key to optimizing value chains and supply chains.

“Additive manufacturing is a really important technology when we talk about digital distributed technology,” stated Stephen Howard, Account Manager at 3D printing software and services developer Materialise.

Howard pointed to the importance of software providers in “enabling digital collaboration between lots of different stakeholders in the manufacturing process, bringing together manufacturers, bringing together designers and engineers and allowing them to collaborate digitally and remotely.”

“We definitely see more companies shifting into or trying to take advantage of decentralized production,” added Howard. “I think it allows for a lot more flexibility, and they’re doing this as a result of global pressures and as a result of supply chain shortages.”

This sentiment was echoed by Pieter Ruijssenaars, CEO of 3D printing supply chain software provider DiManEx. Ruijssenaars argued that DDM is essential because “the world will suffer more from social political problems or natural disasters in the future, so you can’t rely on physical supply chains.”

Ruijssenaars also pointed to the importance of DDM in terms of sustainability, claiming that “AM and digitisation allows you to combine things like cost saving and contributing to a more sustainable world in your supply chain.”

Additive manufacturing and digitization is set to “play a key role in the new supply chains of the future to make them more resilient, more future proof or more sustainable in multiple ways,” Ruijssenaars added.

Intellectual Property (IP) and information security was another key theme touched upon during the panel discussion.

“When you’re working in a distributed manufacturing setup, you move around data all over the world. So you really need to take care of that,” commented Jesper Winther Andersen, CEO and Founder of custom in-ear product manufacturer Earfab.

Key to securing this data is software, according to Howard. “It’s a really key role that software providers play. You really need to take into consideration how software can play a role in IP.” For instance, Howard pointed to a collaboration between Materialise and San Francisco-based software developer Identify3D, with the two companies working to secure IP through blockchain and digital rights management.

Howard also highlighted the digital warehouse as being an area where IP plays a crucial role, especially with regard to the oil and gas and aerospace industries. “I think a lot of these companies are really scared of moving to distributed manufacturing because they’re really scared of the IP getting leaked out and these parts being manufactured elsewhere.”

In terms of scalability, software was again highlighted as being key to DDM. “Software is probably the crux to interconnectivity,” explained Jeremy Haight, Chief Principal Engineer – Additive Manufacturing & Advanced Concepts at global wind turbine manufacturer Vestas Wind Systems A/S. “If you want scalability, you have to have interconnectivity.”

Haight also pointed to the significance of modularity, and the importance of being able to adapt one technology to “do multiple things across the value chain, or produce multiple different types of components that are qualified.”

What is the future of DDM? Ruijssenaars expects two immediate developments. The first is that there will be more hybrid versions of DDM based on different business use cases, with more companies 3D printing locally. Secondly, Ruijssenaars believes that large language models, such as ChatGPT, will see more development and use in this space. These tools can “add to our analytics and make it more intelligent, accurate, and provide more insights.”

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the CO2e calculator discussion panellists. Photo by 3D Printing Industry.