The landscape of 3D printing has always been fraught with myths and misconceptions, often spurred on by market hype. However, there are individuals like Dr. Phil Reeves, a luminary in the additive manufacturing sector, who strives to expose these inaccuracies using their extensive experience and scientific rigor.

Reeves’ journey, from academic to consultant to industry expert, has made him an integral figure in the world of additive manufacturing. His consultation aided the implementation of 3D printing technology in some of the biggest businesses worldwide. His notable influence extends to Stratasys, a global leader in 3D printing, to which he sold his consultancy. Reeves is currently Managing Director at Reeves Insight.

During a keynote presentation on day one of TCT 3Sixty, Reeves addressed the burgeoning subject of sustainability in 3D printing. His objective? To dissect the hype and bring forth the raw, scientific truth about 3D printing’s green credentials, or lack thereof.

Despite being of monumental importance, Reeves asserted, sustainability can sometimes become a “bandwagon” that industries, including 3D printing, hitch onto without fully understanding or addressing the key issues. As per his observations, sustainability in 3D printing has been touted as a means to replace energy-intensive manufacturing processes, reduce raw materials in supply chains, minimize manufacturing waste, and localize manufacturing. Yet, these claims often sidestep the larger issues at play.

According to Reeves, the focus should be shifted towards pertinent environmental concerns, such as global warming, raw material consumption, water usage and wastage, landfill contribution, and hazardous waste production. He argued that truly sustainable additive manufacturing should address these aspects and not just promote convenient claims. As the talk progressed, it became evident that Reeves was preparing to critically dissect the sustainability narrative in the additive manufacturing industry, with his usual keen eye for hype and his scientific acumen at the ready.

How sustainable is 3D printing?

Reeves acknowledges that the 3D printing sector’s self-proclaimed eco-credentials have come under scrutiny. “Let’s address these claims that we make as a way of replacing energy-efficient manufacturing processes,” he states. Traditional manufacturing, especially involving metals, is often likened to ‘hell and brimstone,’ and its greenhouse gas emissions – or scope one emissions – are conspicuous. However, hidden away in the energy supply chain are the oft-ignored scope two emissions, “back at the power station,” which are just as significant.

The image of a sleek, modern AM polymer manufacturing facility was presented in stark contrast to a grimy injection molding plant. This image and the promise of making goods just-in-time, precisely where and when needed, with zero waste – fuels the ‘clean and green’ narrative. But is it the whole truth?

“When we look at greenhouse gas emissions, the vast majority, 25%, the biggest slice of the pie, comes from power generation,” says Reeves. While some countries can boast about their renewable energy prowess, others lag behind, leading to an uneven carbon footprint for localized manufacturing.

Dr. Reeves walks us through an exercise with a sample component, a simple widget – two inches square, made of aluminum, and weighing a quarter kilo – to compare the ’embedded carbon’ in different manufacturing processes, from selective laser melting and CNC machining to metal injection molding and die casting. The embedded carbon is the total amount of carbon emissions associated with producing a product, considering the energy input and its source. “Did that energy come from a Chinese power plant, Malta, Canada, or Norway?” he asks, stressing the importance of considering these factors in the calculation.

He concludes this portion with an important recap regarding energy: specifically, the energy required to boil a litre of water, “about 0.33 megajoules,” which equates to 0.09 of a kilowatt. He further elaborates, “0.09 Kw is about a kilowatt for 5 minutes. It will take your two-kilowatt kettle to boil water in about two minutes.” But how does this energy consumption compare to the energy required to process material using additive manufacturing? As we dive into the details, it becomes apparent that a whole new level of complexity awaits.

Calculating the energy costs of industrial 3D printing

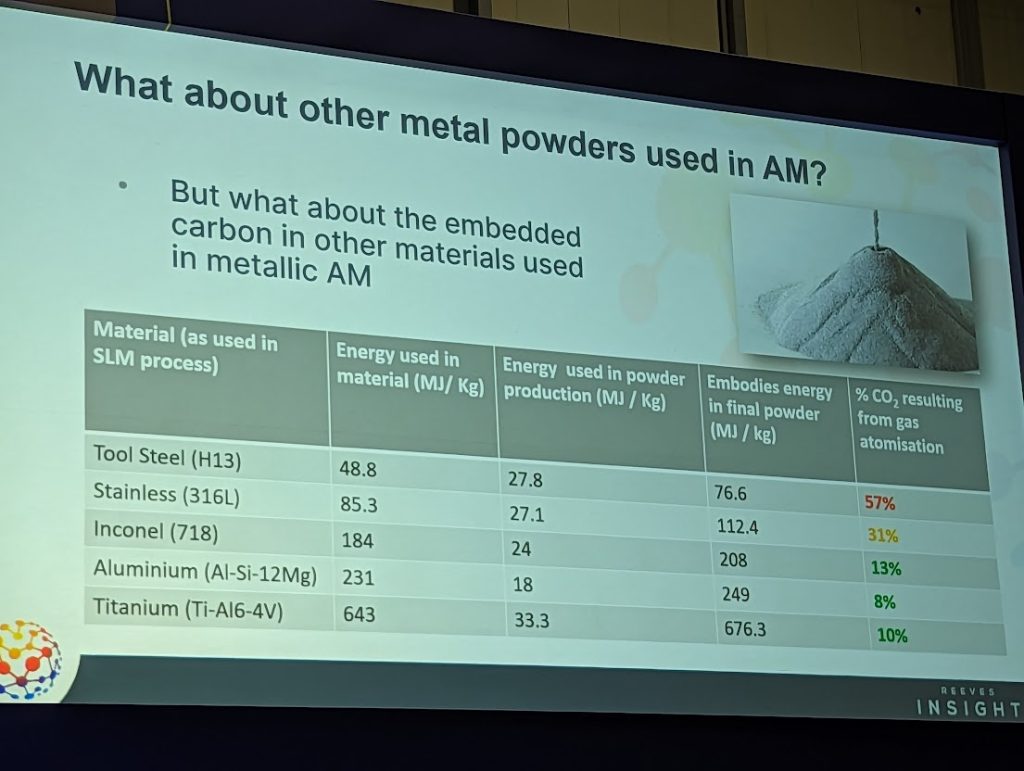

Taking a deep dive into the energy consumption of additive manufacturing processes, Reeves makes clear that the energy requirements of these methods are significantly higher than traditional methods. The energy equation becomes even more lopsided when you consider turning metal into powder for 3D printing.

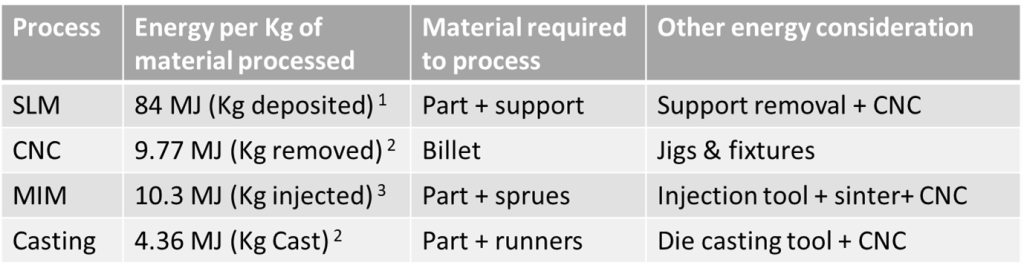

Underscoring the complexities, Reeves makes it clear that 3D printing processes, while versatile and innovative, are not necessarily more energy efficient than traditional methods. While subtractive process CNC machining requires 9.77 megajoules of energy to remove one kilo of material, additive process selective laser melting (SLM) consumes ten times more energy at 84 MJ per kilo deposited. This reframes the narrative of 3D printing as a sustainable alternative to traditional manufacturing methods at this lifecycle stage.

Picking up on the implications for material consumption, Reeves highlights that while working with powder can limit the amount of material used, creating the powder itself is energy-intensive. The paradox continues: in this scenario, the traditional casting method still uses the least amount of material with the least amount of embodied energy, making it more efficient from an energy consumption standpoint than metal additive manufacturing.

Diving further into specifics, he mentions that some materials lend themselves more efficiently to additive manufacturing, noting “certain materials make sense to use in additive manufacturing because the ratio of turning billet into powder is really low.” Reeves gives the example of steel, whereby the process involves extracting ore from the ground, then melting it, then creating an alloy, “That doesn’t use a lot of energy, but then you’re using a large proportion of energy to turn it into powder.” On the contrary, using metals like titanium and aluminum requires a much higher amount of energy due to the electrolysis process involved in extracting them, but proportionally a lower amount of energy to convert into powder.

Reeves also addressed the notion of localized manufacturing, clarifying that not all local manufacturing is sustainable. Giving the example of Norway, which uses 99% renewable energy, making its manufacturing processes less impactful on the environment. On the other hand, countries like India, which relies heavily on fossil fuels, lose around 63% of all the power generated before it reaches the factory or home due to infrastructure inefficiencies.

Putting it in perspective, he states, “If we put our SLM machine in Norway, we really have no impact on the environment. If we put it in India, we emit almost six kilos of CO2 by locally making”. Thus, while 3D printing offers the advantage of producing items near where they’re needed, the sustainability of this approach greatly depends on the energy sources and efficiency of the location.

Concluding the segment, Reeves highlighted the environmental impact of transporting goods, saying, “For every tonne of cargo that you move every kilometer, a very large container vessel emits about three grams of CO2. If you take that to air freight, to do the same thing to one tonne of cargo, one kilometer, it’s almost half a kilo.” Hence, when considering the overall carbon footprint of manufacturing processes, both energy consumption and transportation methods need to be considered.

Sustainability: Beware of blanket claims and a vital consideration

In his concluding segment of the presentation, Reeves conveyed the core message that the sustainability of 3D printing isn’t as black and white as it seems. He argued that “the blanket claims that we’re starting to see made about 3D printing are not entirely accurate.” The sustainability of 3D printing hinges on myriad factors, including part design, manufacturing location, distribution distances, and end-use applications.

To further illustrate his point, Reeves provided an example involving an aerospace component, presented as a hypothetical ‘widget.’ The widget, he explained, “is a 1.58 kg part, requiring 12.5 kg of aluminum to make.” He further outlined that manufacturing the widget with 3D printing was significantly more efficient than traditional CNC machining, particularly when factoring in the recycling potential of aluminum, which sits at an impressive 76% globally.

But the most crucial consideration, according to Reeves, is not manufacturing or distribution but the usage phase of the widget’s lifecycle. He detailed, “The usage phase contributes 98% to the environmental impact for an aerospace part.” Reducing weight through optimized designs can lead to significant CO2 emissions reductions, especially for short-haul aircraft, where weight is closely linked to fuel consumption.

For example, Reeves stated, “Our one component, where we used additive manufacturing to reduce 20% of its weight, had the same impact on the environment as taking a pickup truck off the road.” However, he cautioned such significant benefits are not universal and highly depend on the specific application and product lifecycle.

Reeves was also quick to debunk the commonly held belief that localized manufacturing is a silver bullet for sustainable production, stating, “Don’t use localized manufacturing as a metric when you’re talking about sustainability… it has such a tiny impact on the overall environmental footprint of the product.”

Finally, he emphasized the need to balance sustainability with economic viability. “Good sustainable practice has to tie to economics,” he urged. Innovative approaches, such as charging customers a portion of the fuel savings made possible by lighter parts, can help turn sustainable manufacturing into profitable manufacturing.

In conclusion, Reeves believes that 3D printing or additive manufacturing indeed plays a crucial role in sustainable manufacturing. However, he urges a holistic, science-based approach rather than leaning on perception or hype, underscoring that “you have to look at the lifecycle benefit.” The promise of 3D printing for sustainability lies in its power to optimize design, material use, and lifecycle impacts in ways traditional manufacturing can’t. It’s not a silver bullet but another tool in our arsenal as we strive for a more sustainable future.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Dr. Phil Reeves at TCT 3Sixty 2023. Photo by Michael Petch.