Reporting from AM Forum Berlin 2023, we saw how 3D printing is used in the supply chain in the automotive, mobility, and defense sectors.

This article provides insights into the railway industry supply chain from Siemens Mobility and SNCF. Plus, the question of the effectiveness of using 3D printing to solve supply chain challenges is addressed by Stratasys and CTC, an Airbus company.

The 3D Printing Industry Awards are back – nominate now.

How the railway industry is using 3D printing in the supply chain

Christian Ochs, the Head of Additive Manufacturing at Siemens Mobility GmbH, describes the elements that make the railway industry an interesting case study for 3D printing, “You also have very sophisticated standards and norms. And you have a lot of regional differences between countries.”

Ochs also underscores the importance of supplying spare parts with reliability and on time. He raises a noteworthy point: the ever-present high-cost pressure in the railway business. The need for high-quality and cost-efficient parts in a sector with varying regional norms presents a unique set of challenges for additive manufacturing. He suggests a possible solution is collaborating with customers and authorities to fast-track the process of achieving more economical use cases.

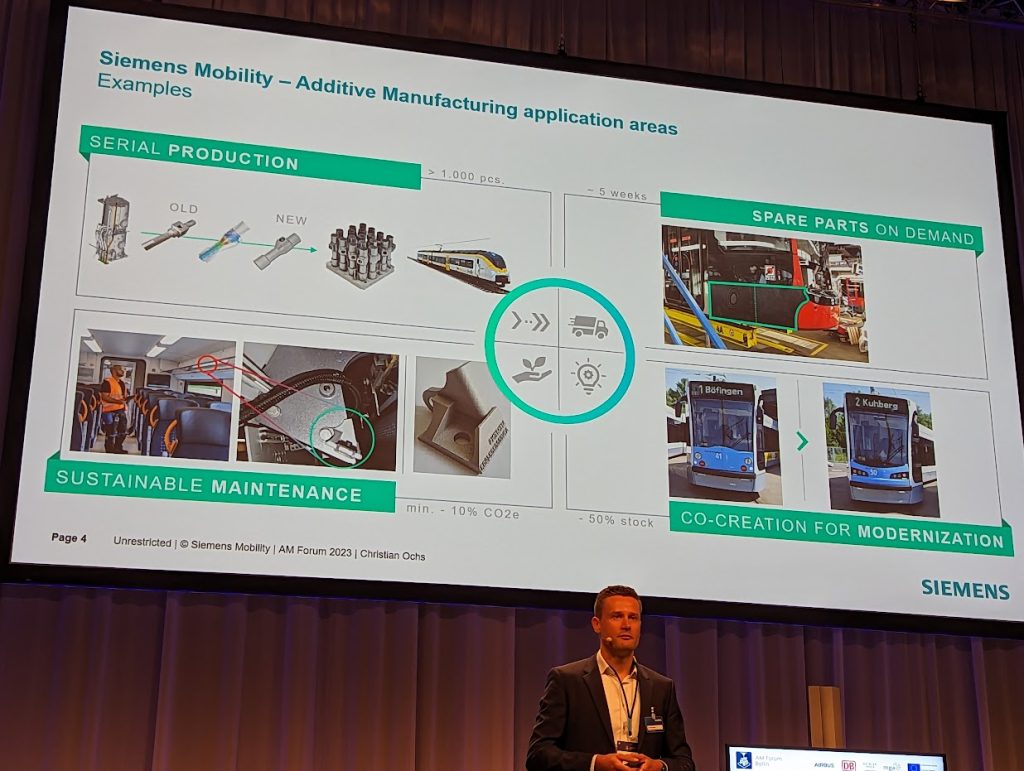

Ochs also highlighted how additive manufacturing is already modernizing railway fleets. Trains undergo a total overhaul after 16 or 18 years, often including the introduction of new monitors and air conditioning systems that are heavier than their predecessors. 3D printed parts, he noted, can be up to 50% lighter due to intelligent design, enabling upgrades without significant weight increases. This not only saves costs but also avoids the time-consuming and expensive process of obtaining new approvals.

Future fleets of vehicles may rely heavily on the promise of lifetime availability for parts that 3D printing could offer. However, Ochs stressed that additive manufacturing isn’t just a contingency plan for when traditional manufacturing methods fail. “When developing our next generation of trains, we [ask] where can we [introduce] additive parts? Right from the beginning to really use the design freedom,” Ochs said.

The Siemens Mobility Head of Additive Manufacturing also revealed how his firm was changing the landscape of vehicle repairs with additive manufacturing.

Ochs explained, “We did an additive redesign; we segmented [the vehicle] into parts, which has the benefit that just one part can be exchanged.” This method, he noted, was particularly useful in case of accidents, which can happen between tramcars and vehicles. “We modernized it, and we did this in a co-creation together with a customer,” he elaborated. “And the benefit is stock levels are reduced.”

The process also had positive implications for internal operations. Siemens created a small repair unit via Selective Laser Melting (a type of 3D printing that uses a high-powered laser to melt and fuse fine metallic powders), saving materials and energy. “We created a new smallest repair unit via selective laser melting, which now can withstand 2.5 times the load and brought into the vehicle benefits 95% less material consumption and of course less energy consumption as well,” Ochs stated.

Not limited to bespoke parts, Siemens has also embarked on serial production of 3D printed components. “The example here is a nozzle which has five times the performance a conventional part could reach and is 70% lighter,” said Ochs. To date, Siemens has used laser powder bed fusion to produce over 100,000 pieces.

Despite these advances, the journey to additive manufacturing of spare parts has not been without challenges. “Of course, we scan our inventories to see if there are parts that fit better to be produced additively…all these parts in the past were designed for conventional manufacturing,” Ochs noted. The costs of 3D printing can often be higher, he warned, hence the need to factor in additional benefits such as inventory reduction and avoidance of penalties due to vehicle downtime.

Industrialisation of additive manufacturing at SNCF

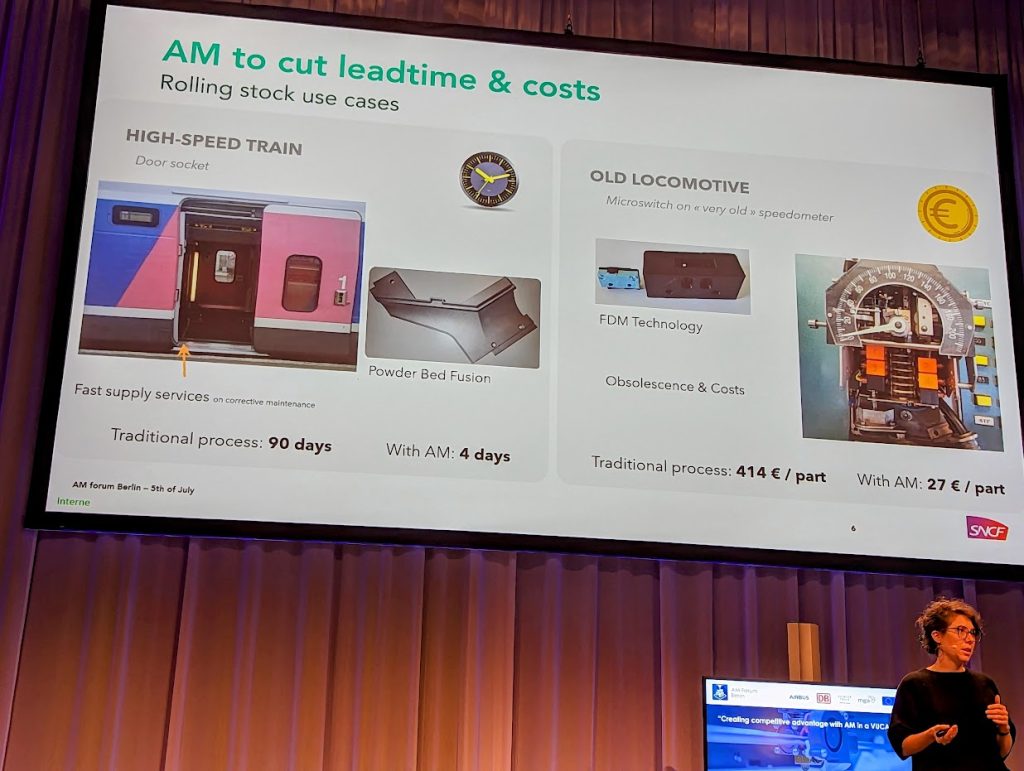

France’s national state-owned railway company, SNCF, is also looking at an innovative approach to improving performance and efficiency. Hélène Sapardanis, project manager of innovative materials and processes at SNCF, gave an overview of the ongoing projects that aim to integrate 3D printing into railway operations. “We are really pushing for the industrialization of additive processes in the railway sector,” she explained.

The project Sapardanis works on is entitled ‘Additive4Rail’, largely aimed at transforming maintenance processes in the railway industry. SNCF’s commitment to maintenance is demonstrated by the fact that it accounts for 30% of production cost for rail service. Primarily, the focus is on the rolling stock (locomotives, carriages, wagons, etc.). From repairing key components, transforming trains, upgrading and overhauling to modifying trains, the scope is immense.

With a considerable 200,000 spare parts references for infrastructure and rolling stock, the potential for additive manufacturing is substantial. “About 10% of this can be transformed through additive manufacturing,” Sapardanis reveals. She highlights how 3D printing can help reduce operational downtime by expediting the production of necessary parts, even recalling a time when a missing cap for a toilet held up a high-speed train.

The technology also offers solutions to obsolescence issues. For older trains where the original supplier may no longer be in operation, creating the required components becomes a challenge. Here, additive manufacturing could step in to fill the void, keeping these machines in operation.

There are hurdles to be overcome for the full integration of additive manufacturing in the railway sector. For instance, most of SNCF’s spare parts designs are in 2D, a format not directly compatible with 3D printers. Additionally, from a regulatory perspective, there’s a scarcity of material and process data from a user point of view, coupled with stringent flame retardant requirements. Additive manufacturing costs also remain prohibitive, particularly for larger parts. And perhaps most crucially, adopting additive manufacturing means an entire rethink of the supply chain, from engineering to purchasing.

SNCF and its partners aim to develop new materials, increase the use of existing materials, and reduce the cost of components. Specifically, the project has set a goal to expand the flame-retardant material portfolio in the railway sector. Currently, only one suitable material exists on the market, which is expensive, prompting the need for alternatives, according to the project manager.

As Sapardanis notes, the initiative includes a plan for certification right from the project’s inception. It’s not an afterthought, for as she says, it’s important not to get to the end of a project and wonder, “what are we going to do with this part?”

The project has already seen tangible results, with an additive manufacturing cell at a maintenance center in Saintes, near Bordeaux. They’ve managed to produce parts in-house, offering a glimpse of the future direction of railway maintenance. One particular achievement is the production of two shafts, each weighing around 60kg. While the exact application is still to be determined, the success of this production hints at the promising potential of additive manufacturing in the railway industry.

Will 3D printing solve all supply chain issues?

Does using 3D printing to solve supply chain challenges make sense for everyone? Andreas Langfeld, President EMEA at Stratasys, sees a need for less hype around additive manufacturing and more focus on current possible use cases rather than fantasizing about printing millions of parts in a day. “We need to provide a full workflow solution,” Langfeld said, underscoring the importance of offering not just a 3D printer but also software, necessary materials, and certification proofs. He argued against companies aiming to produce a large percentage of parts through additive manufacturing as a starting point. Instead, a single part with a rapid return on investment could yield significant savings and open the way for further additive manufacturing.

Similarly, Marc Fette, CEO of Composite Technology Center (CTC), an Airbus company, pointed to the complexity of integrating additive manufacturing into the aerospace sector. Despite having “100 parts which are thermoplastic now,” Fette said, “It’s a little number at the moment. It’s a niche, and it’s not wired into manufacturing.” A crucial challenge lies in the certification and qualification processes necessary for materials, methods, and designs in industries like aerospace, similar to railway and shipbuilding.

So, how to advance? Sascha Hartig, Coordinator of Additive Manufacturing for the German Navy, revealed that there is indeed a plan to introduce 3D printers to every navy ship. He emphasized that this wouldn’t be a one-time implementation of multiple machines but rather a carefully executed, iterative process involving training crew members on using these printers.

The discussions at the AM Forum Berlin 2023 reflect the burgeoning interest and potential of 3D printing across industries, including the mobility sector. While the technology offers transformative solutions, especially in sectors with intricate standards and needs, its integration is challenging. Industry leaders call for a pragmatic approach, prioritizing real-world applications, workflow solutions, and addressing regulatory hurdles. The journey to harness the full potential of additive manufacturing is ongoing, with stakeholders continuously exploring avenues to optimize its benefits.

Tell us who is leading the industry. Nominations are open for the 3D Printing Industry Awards.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter, follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.