Alba Orbital, a Scotland-based PocketQube satellite manufacturer, has successfully completed its second launch mission of 2022 with the help of its 3D printed nanosatellite deployers.

Hitching a ride on Rocket Lab’s Electron rocket, the firm launched four of its PocketQube satellites (Alba Cluster X) from Rocket Lab Launch Complex 1’s Pad A, located on New Zealand’s Mahia Peninsula. The cluster was launched in early May under Rocket Lab’s ‘There And Back Again’ mission, which involved a total of 34 satellites being taken into sun-synchronous orbit.

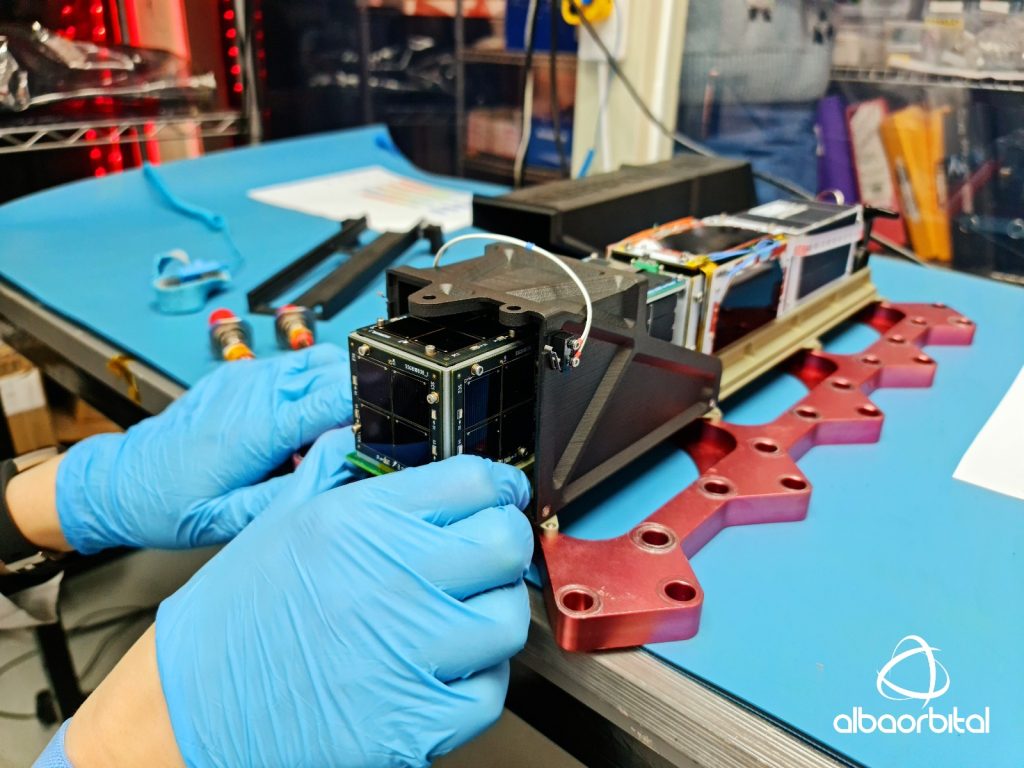

To distribute the four PocketQubes in space, Alba leveraged its entirely 3D printed AlbaPod v2 satellite deployer. The system was produced by CRP Technology and is made of the firm’s own Windform XT 2.0 material, a carbon fiber-reinforced composite.

“We’re delighted to be Alba Orbital’s mission partner once again,” said Peter Beck, Founder and CEO of Rocket Lab. “The Alba Orbital team have proven that incredibly small satellites can be highly capable and deliver tangible insights and services back down to Earth at a fraction of traditional satellite costs. Making it faster, easier and more affordable to access space is a mission we share, so we’re excited to make it possible with Electron.”

Windform XT 2.0 and the AlbaPod v2

Designed for use in laser powder bed fusion, Windform XT 2.0 is a part of CRP Technology’s Windform TOP-LINE range of composites. The material is based on the original Windform XT offering but features improved mechanical properties such as an 8% increase in tensile strength and a 46% increase in elongation at break.

Thanks to its carbon fiber reinforcements, Windform XT 2.0 can be used to 3D print durable prototypes as well as functional end-use parts. CRP Technology has rated the material ‘HB’ according to the UL 94 flammability test, which means it provides the heat resistance and flame retardancy characteristics necessary for many high-temperature aerospace applications. This includes parts in close proximity to the open flames of thrusters and boosters.

In 2020, Alba Orbital started using Windform XT 2.0 to 3D print its AlbaPod v2 deployers, owing to the material’s excellent blend of mechanical and thermal properties. The shell, ejection mechanism, door assembly, and other components of the deployer were redesigned for 3D printing. The company then managed to integrate nine of its PocketQube satellites into the AlbaPod v2 ahead of the launch of the Cluster 3 mission in December 2020.

More recently in 2022, Alba launched five of its AlbaPods into orbit as part of SpaceX’s rideshare program. The systems deployed thirteen PocketQube satellites in space, where they’ll be used for a variety of research missions.

Other composites in the Windform materials lineup include Windform RS and Windform SP, which was recently used to 3D print an athletics track shoe. Named Pleko, the shoes were designed by CRP Technology with help from Venetian middle-distance runner Miro Buroni.

Tracking night lights data

The latest set of Alba Cluster X satellites included one of Alba’s own Unicorn-2 PocketQubes, as well as three additional PocketQubes for Alba’s customer: weather app developer ACME AtronOmatic. Each of the four satellites is currently deployed in its own unique orbit around 500km from the Earth’s surface.

The Unicorn-2, specifically, is carrying an optical night-time imaging system capable of monitoring light pollution levels across the world. This night lights data is expected to provide insights into various human activities such as armed conflicts, disasters, urbanization, fishing, energy use, and greenhouse gas emissions. The nanosatellite has already phoned home on its first pass.

Additionally, this launch was the first time Rocket Lab was able to capture the first stage of its Electron launcher in mid-air using parachutes and a helicopter. The firm hopes to one day see the Electron become the first reusable orbital small sat launcher.

“It’s a pleasure to be working with Rocket Lab again on this exciting mission,” said Tom Walkinshaw, CEO and Founder of Alba Orbital. “We are thrilled to launch the first of our imaging constellation dedicated to imaging the earth at night on board the Electron rocket. From day one, Alba Orbital’s mission has always been to democratise access to space, and Rocket Lab has demonstrated that they are whole-heartedly committed to the same vision.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Alba Orbital’s 3D printed AlbaPod deployer being attached to the kick stage of Rocket Lab’s Electron rocket. Photo via Alba Orbital.