3D printing materials and services provider CRP Technology has deployed its proprietary Windform TOP-LINE range of polymers to fabricate a series of nanosatellites and PocketQubes for clients in the aerospace sector.

The company’s powder-based 3D printing materials, which have a history of being utilized in the motorsport industry, are now increasingly being leveraged by businesses with space-faring ambitions. Working with aerospace firms Alba Orbital and Mini-Cubes, CRP Technology, and its partner firm CRP USA, have recently utilized the enhanced thermal and mechanical qualities of Windform XT 2.0, to build a string of optimized pocket satellites and deployers.

Now, as Alba Orbital’s next trio of miniature devices approaches their launch date in December 2020, Franco Cevolini, VP and CTO of CRP Technology, has explained the benefits of using Windform within their production.

“Unlike many technologies that were originally developed for aerospace that are then adapted to motorsports, Windform XT 2.0 is a purely motorsports-driven material,” explained Cevolini. “Now Windform XT 2.0 and all the Windform composite materials are used in the most advanced industry sectors to manufacture complex and harsh final parts and functional prototypes.”

CRP’s Windform TOP-LINE materials

CRP was founded in 1970 as Roberto Cevolini & C, and the original company was primarily focused on producing specialist car components and CNC machining parts for Formula 1 teams. The firm went on to become CRP Meccanica, a CNC machining services provider for clients in a range of industries and established its subsidiary CRP Technology as a means of providing them with a 3D printing alternative.

As CRP Technology continued to expand across the U.S. and Europe, it maintained strong links to the motorsport industry, and its other partner company CRP USA was set up near NASCAR HQ with this in mind.

Leveraging its vast engineering experience, CRP Technology went on to develop its first Windform material in 1996, and this was succeeded by Windform XT in 2005, the first carbon fiber-reinforced composite for SLS 3D printing. The aero-optimized composite took the performance benefits of motorsport metals from the wind tunnel into a wider range of applications and featured enhanced mechanical and thermal characteristics.

The company’s current range of Windform TOP-LINE composites is built on this motorsport heritage, but now they are also used within a variety of other highly-demanding prototyping and end-use applications. At present, CRP’s lineup includes the successor to its XT composite, XT 2.0, as well as the SP, FR1, FR2, GT, LX 3.0, RL, FX BLACK, and GF 2.0 materials, and each has been custom-made with a certain use in mind.

Windform RL for instance, is an elastomer with enhanced stretchability, while Windform FR2 is a flame retardant glass-fiber-reinforced material, which is designed for use within the aerospace and automotive sectors. A wide range of different businesses have adopted Windform FR2 in recent years, on the basis of its electrical insulation, stiffness, resistance to temperature, and flame retardance, including electric motorcycle manufacturer Energica.

The company deployed CRP’s material as a means of producing cell pouch frames for its battery pack prototypes, which went on to pass a series of road tests. Elsewhere, safety specialist Joyson Safety Systems (JSS) used CRP’s Windform SP carbon fiber-filled polyamide-based composite to manufacture a functional airbag housing container prototype.

More recently, CRP Technology and CRP USA have partnered with a number of aerospace firms to use the strength resistance qualities of CRP Technology’s Windform composites, as a means of printing flight-ready satellites.

3D printing flight-ready satellites

CRP Technology’s Windform XT 2.0 material, in particular, has proven to be rugged enough to be used by Alba Orbital, Mini-Cubes, and many more to 3D print a selection of miniature satellites and deployers. The composite features substantially-improved mechanical properties compared to Windform XT, including increases of 8 percent in tensile strength, and 46 percent in elongation at break.

As a result, the material allows for the creation of accurate, reliable, and durable prototypes, and its rigidity makes it well-suited to functional end-use applications too. Windform XT 2.0 has also been rated ‘HB’ according to the UL 94 flammability test, meaning that it has the necessary retardancy to allow its use in proximity to open flames like thrusters or boosters.

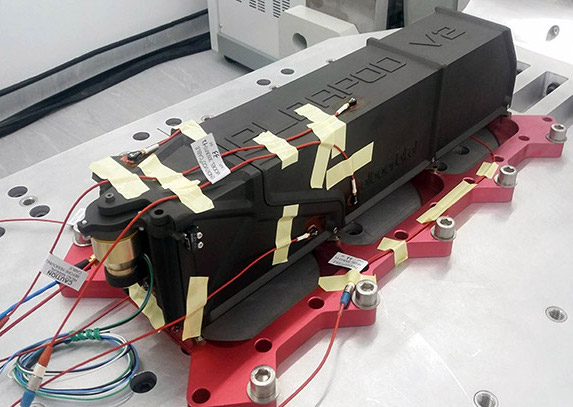

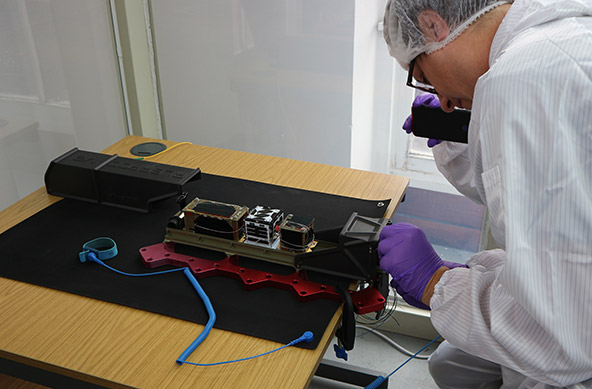

As part of a collaboration with Mini-Cubes, CRP USA 3D printed three flight-ready picosatellites named ‘Discovery.’ The satellites were manufactured using Windform XT 2.0 and the SLS 3D printing process, and according to Joe Latrell, CEO of Mini-Cubes, the material proved to be ideal for the job.

“The combination of strength and ease of use made the material a natural choice for us,” explained Latrell. “We knew that we wanted to use additive manufacturing for Discovery, but understood that it would be hard to find something that would work in the harsh environment of space. When we discovered Windform XT 2.0 and after looking at its properties, it was a simple choice.”

CRP’s Windform-based satellites, ready for lift-off?

Since CRP USA produced the first PocketQubes, Mini-Cubes’ devices have already passed a number of safety tests. The satellites have undergone a 20kg load test, a NASA GEVS-7000 specification vibration evaluation, and proven capable of surviving temperatures ranging between 50°C and -40°C.

The final, and most important test for the Discovery will come in Q2 2021 when it’s sent into orbit for the first time, but all signs suggest that the launch will be successful.

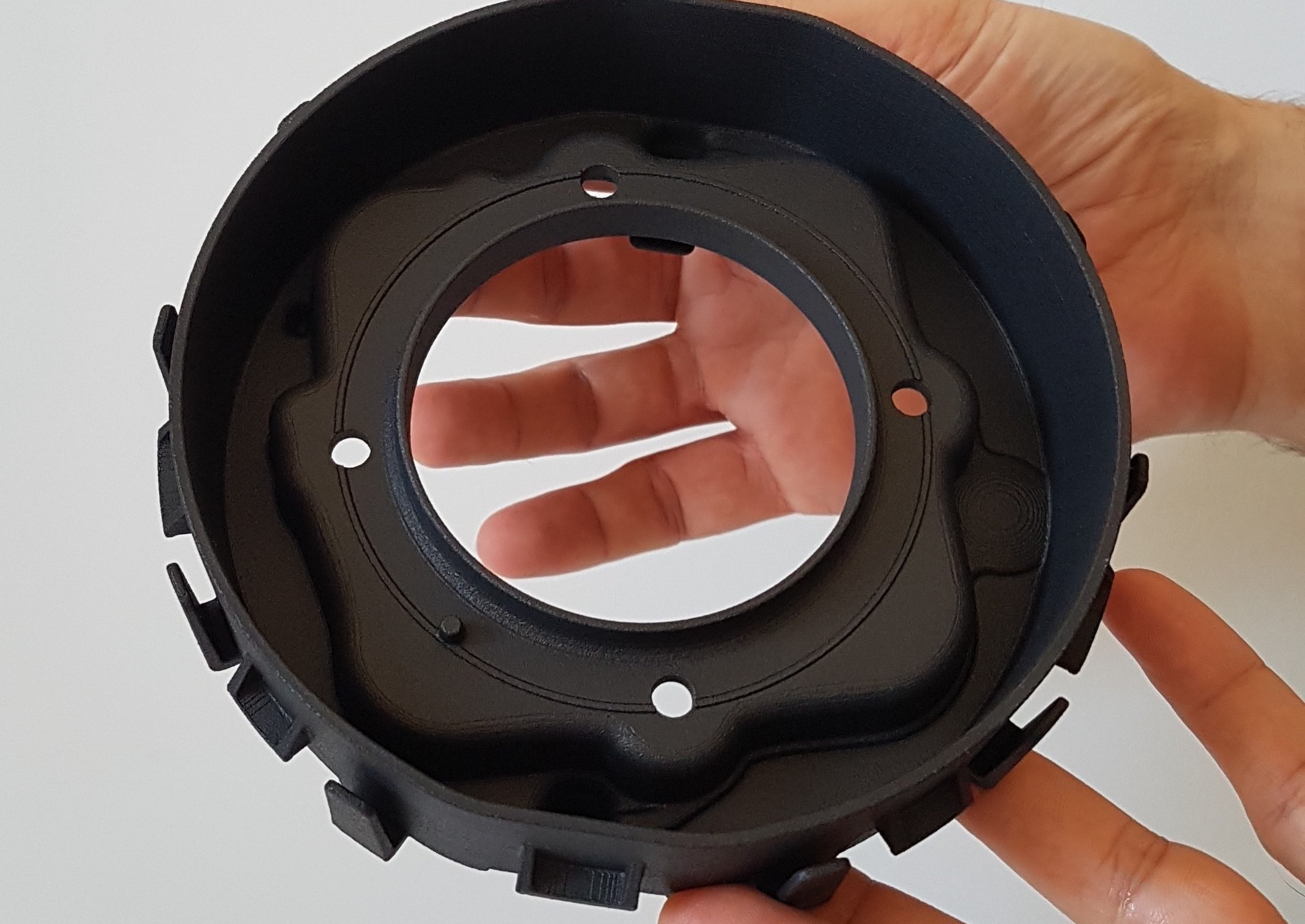

CRP Technology’s client, Alba Orbital, found similar performance gains could be found in the production of its ‘Alba 2’ line of PocketQube deployers. The lightweight nature of Windform XT 2.0 enabled the company to reduce the weight of the device by 60 percent compared to that of its original version.

What’s more, CRP Technology’s material allowed the Alba Orbital team to produce a complex design that would have been impossible using traditional processes, while doing so in a fraction of the time. The company has since used the 3D printed AlbaPod v2, manufactured by CRP Technology, to launch six nanosatellites into orbit, where they remained for a total of 100 days.

Now Alba Orbital is working with Momentus to deliver another ten of the devices into space, by hitching a ride on the plaza deck of SpaceX’s Falcon 9 launch vehicle. The spacecraft will take off from the Kennedy Space Center in December 2020, and all going well, the companies aim to collaborate in the future, propelling more commercial devices into space.

According to the Alba Orbital team, CRP Technology’s material has been vital to the success of its pocket-sized satellite deployer. “The most innovative aspect of the project was the sheer number of components we switched over to Windform XT 2.0,” commented the team.

“Not only was the shell redesigned in the material, but also the moving ejection mechanism and door assembly. Some parts are structurally critical to the assembly as a whole,” they added.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a PocketQube satellite that was 3D printed by CRP USA. Photo via CRP USA.