Researchers from the University of North Dakota (UND) have been awarded a $750k NASA grant to develop a 3D printed spacesuit.

Working alongside staff from the Marshall, Johnson and Kennedy Space Centers, Pablo de León, Professor and chair of UND’s space studies department, will conduct a three-year R&D project into the concept’s viability. The additive garment, which is set to be nicknamed ‘NDX-3,’ will be fabricated using a combination of flexible polymers, and eventually compared to conventional spacesuits via motion capture testing.

“So far, all pressure and spacesuits have been built using traditional sewing techniques,” explained León. “They take literally thousands of hours of very skilled sewing artisans to build one spacesuit, and they are very fragile as well. It is important to rethink the way spacesuits are made, and we have potentially found that 3D printing can help with this.”

“As we venture beyond low Earth orbit, astronauts will need a reliable method to repair and adjust their suits.”

Transitioning from sewing to manufacturing

Over the past seventy years, spacesuits have largely been constructed in the same way, using traditional sewing techniques to stitch together pieces of urethane nylon, various metals, and wearable polymers. The process takes thousands of hours for a skilled sewing artisan to complete, and even the finished garments are ancient technology compared to modern aerospace standards.

What’s more, the suits aren’t good value for money, costing around $2 million each to make, and as they’re tailored to each astronaut, they usually can’t be reused either. UND began collaborating with NASA a few years ago to change the way spacesuits are made, and with the aim of designing an enhanced, more cost-effective alternative design.

Although Professor de León and his faculty have been working on the project for some time, they’ve recently opted to integrate 3D printing into the pressurized garment’s design. It was only when the prospect of deep space exploration was considered by the team, that they switched to additive manufacturing, and gained the NASA contract as a result.

“On Mars and beyond, astronauts won’t have the luxury of an army of seamstresses or seamsters in their planetary habitat to take care of their suits, and asking for the parts from Mission Control would take more than a year,” explained Professor de León.

“So, what we will try to do, is to build a pressurizable space suit using mostly 3D printing,” he added. “NASA has decided to fund our lab, since potentially this can change the way space suits will be manufactured in the future, and help to reduce “Earth-dependency,” which is one of the space agency’s goals.”

UND’s ambitious new 3D printed spacesuit

Over the course of the three year NASA contract, the UND team will assess the potential of additive manufacturing technologies in spacesuit design by developing and 3D printing a full garment. Although the researchers are still in the early stages of the design process, they have already modelled its desired appearance and conducted numerous material evaluations.

At first, the team’s design was rejected as “too green,” but they improved their techniques, printed and pressure tested parts using a range of different flexible filaments, and now NASA has requested a full prototype. As the project progresses, UND’s space department will work more closely with NASA, to pool expertise, and utilize the agency’s advanced 3D printing technologies.

“In the past, we have been very close to NASA’s centers and for this particular project, we will need their expertise, input and specialized equipment,” said León. “NASA has been a pioneer in 3D printing for decades. It has some of the most sophisticated equipment and the best experts, to help us tackle some of the problems we will find during this project.”

“We will be working with the Marshall, Johnson and Kennedy Space Centers since they have expertise in several of the areas we will use for developing the prototype, and the equipment to print it.”

Once the team has created their additive prototype, they will subject it to a series of motion capture tests, to compare its performance to that of a conventional flight suit. Given that the garment is designed to be used on Mars, the motion capture tests will simulate the conditions of outer space, allowing the researchers to accurately measure its reliability.

Factors such as the spacesuit’s flexibility, mobility, and walking kinematics are all set to be closely monitored during, to make sure that the suits are as easy to move in as possible. In the project’s later stages, body-scanning techniques will be used to create custom-fitted prototypes, that are designed to “perfectly fit” future astronauts.

“We feel that for long duration spaceflight, it is better to have a suit that fits you perfectly and has been made for you, than taking a ‘one size fits all’ approach,” concluded Professor de León. “With traditional techniques it would be costly and very difficult, but using additive manufacturing you can do just that.”

NASA’s 3D printed predecessors

NASA has commissioned a number of research projects over the years, to investigate the potential of 3D printing in creating spacesuits, and developed various prototypes along the way.

As far back as 2015, NASA announced that its Z-2 prototype spacesuit would be produced using 3D scanning and additive manufacturing technologies. The suit itself was designed to be made out of high-durability composites, in order to enable greater mobility, and protect its wearer from the harsh environments of space.

More recently in January 2018, The Austrian Space Forum (OeWF), tested spacesuits as part of a month-long simulated field mission to Mars. As part of the evaluation, scientists from 25 countries around the world traveled to a barren area of Oman, to simulate the conditions of the red planet.

Elsewhere, Raul Polit-Casillas, a systems engineer at NASA’s Jet Propulsion Laboratory, outlined the potential aerospace applications of chainmail-like 3D printed materials. According to the technician, the additive fabrics could either be leveraged as spacecraft shielding or scaled down to provide protection for astronauts in the form of spacesuits.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

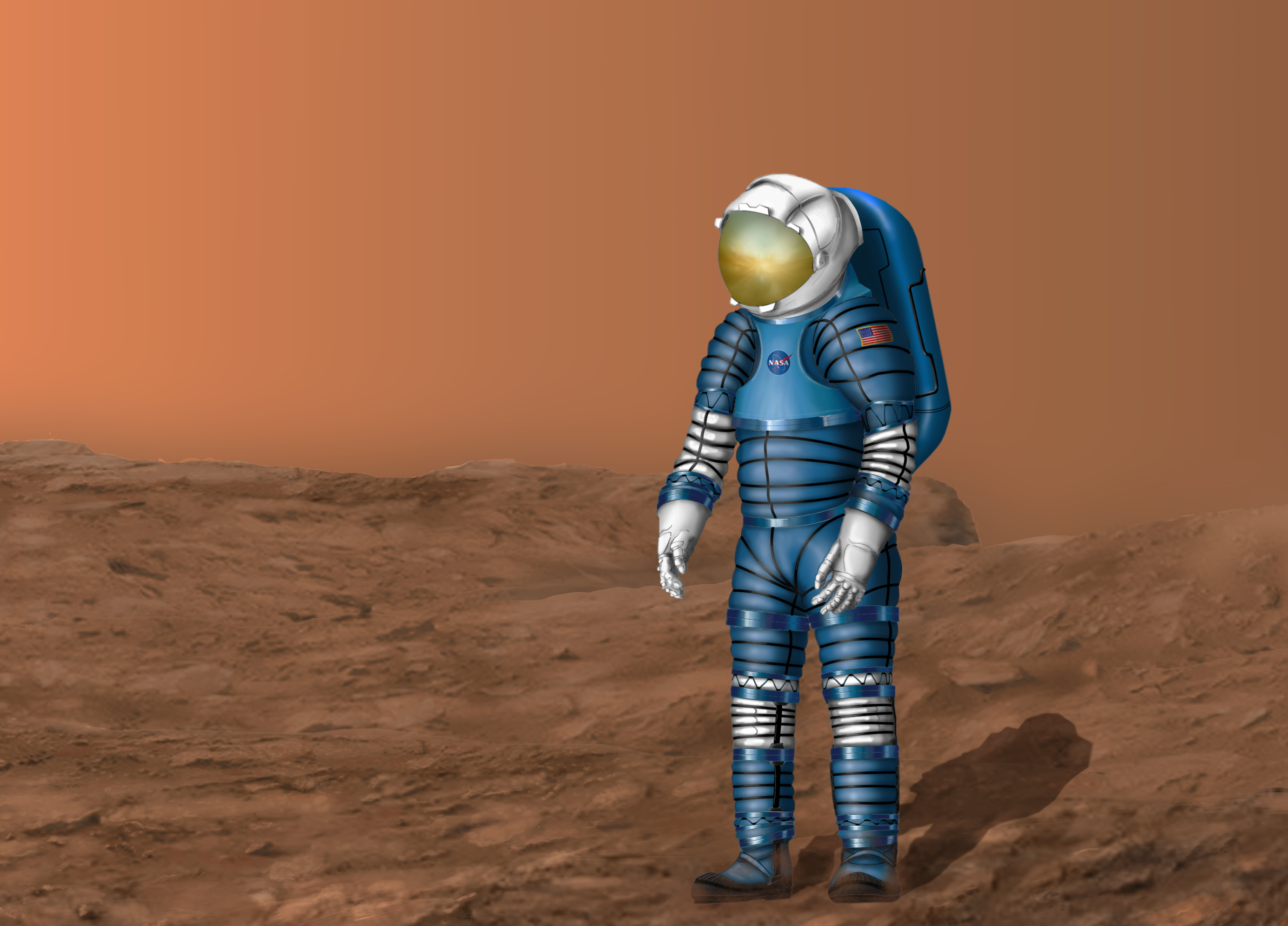

Featured image shows one of the UND team’s previous spacesuits being tested in conditions that replicate those on Mars. Photo via Pablo de León, UND.