Scottish aerospace firm Alba Orbital has announced the successful use of its PocketQube launchers to fire several miniature satellites into orbit.

3D printed entirely from CRP Technology’s Windform XT 2.0 composite, Alba Orbital’s low-cost AlbaPods are designed to drive the accessibility of firing small satellites into space. With this in mind, five such launchers have now been propelled into orbit by a SpaceX Falcon 9 rocket, where they’ve gone on to deploy thirteen PocketQube devices onto courses that will see them engage in various research missions.

“Congrats to Alba Orbital and to all the teams that have flown with them, for all their hard work,” said Franco Cevolini, CEO and CTO of CRP Technology. “We are very proud to be a part of this, as a supplier of materials and technology that are integration and space-proven!”

“The successful mission demonstrates once again the extreme value of Windform for high-performance, heavy duty and mission-critical applications.”

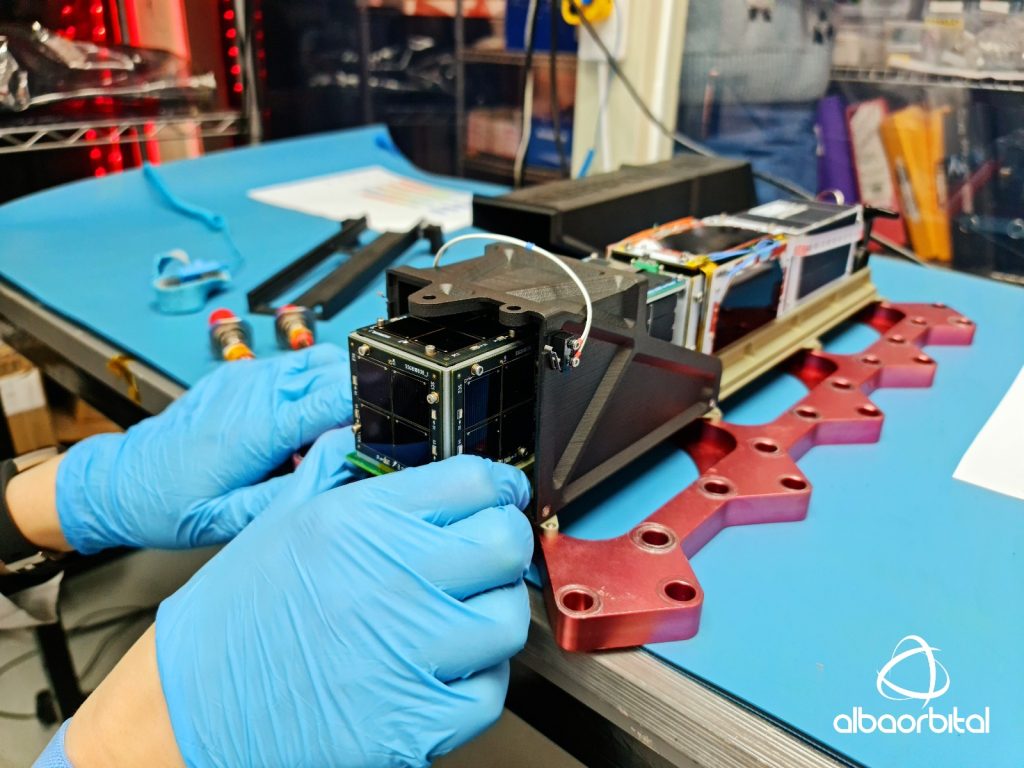

The Windform-reinforced AlbaPod

Based in Glasgow, Alba Orbital is a firm focused on becoming a UK hub for helping fledgling satellite projects get off the ground. To best achieve this, the firm doesn’t just offer its support to the innovators behind these PocketQubes, but develops and supplies its own platforms and parts to private enterprises, universities and space agencies around the world.

In addition to its own Unicorn-2 satellites, Alba Orbital markets services based around the AlbaPod as well, a deployer it says can drop devices into low earth orbit (LEO) for as little as $100,000. To keep these launchers so low-cost and accessible, while building them tough enough to withstand the rigors of space, the firm has had to refine their production process, including via the adoption of 3D printing.

One way in which the firm has integrated the technology into its deployer manufacturing workflow, is through a long-running partnership with CRP Technology. Back in 2020, the material developer and service provider revealed that Alba Orbital had begun using Windform XT 2.0 to build its AlbaPods, in a way that yielded accurate and durable prototypes, as well as functional parts.

CRP Technology’s carbon-fiber-reinforced composite is also rated ‘HB’ according to the UL 94 flammability test, meaning that it can be used close to the open flames of thrusters or boosters. As a result, it should come as no surprise that its developer has been able to work with Alba Orbital to 3D print a launcher with such reliability and accuracy, that AlbaPod is planning three more launches into LEO later in 2022.

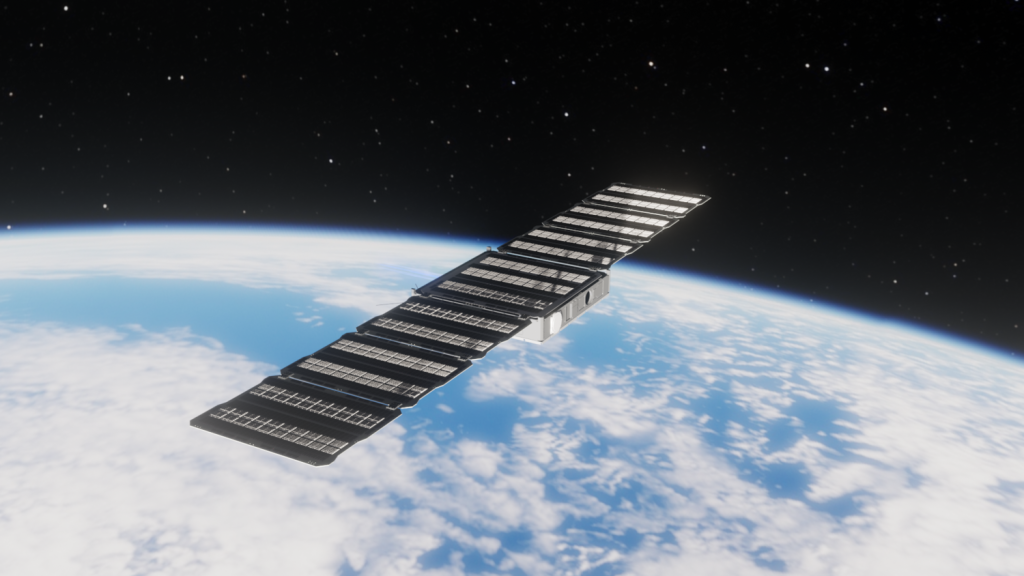

Alba Orbital’s SpaceX launch

Launched on January 13, 2022, Alba Orbital’s ‘Alba Cluster 3 & 4’ mission may have been the third of its kind to be facilitated by SpaceX’s rideshare program, a service in which the firm offers to fire payloads of up to 200kg into orbit for $1 million, but it was the first to fly via the Falcon 9 Transporter-3, and also saw the largest AlbaPod cluster deployed to date.

During the mission, the Transporter-3 fired a total of 105 commercial and government micro and nano-satellites from a launchpad in Cape Canaveral, before deploying them 326 miles above Florida’s east coast. Once they’d reached a polar sun-synchronous orbit, a cluster of 5 AlbaPods helped propel a select 13 of the PocketQubes into position, with four of these breaking new ground in research.

One of those trailblazers, the ‘TARTAN-ARTIBEUS -1,’ was developed as part of an open-source project at Carnegie Mellon University, with the aim of introducing the first battery-less, intermittent, orbital-edge computing nanosatellite. The launch of PocketQube ‘GRIZU-263a’ and pico-satellite ‘PION-BR1,’ meanwhile, marked both Turkey’s and Brazilian start-up PION Labs’ first of their kind to enter orbit.

Notably, among the other launches, ‘UNICORNs 2A, 2D & 2E’ marked Alba Orbital’s first launch of an Earth observation satellite designed to capture images of the planet at night, while teams from the likes of TU Delft, Ariel University, AMSAT-EA, Hydra Space, Innova Space and the European Space Agency, also got their projects off the ground.

Since launch, CRP Technology says that these satellites have begun transmitting their findings back to Earth, making the rideshare mission a success. More broadly, the mission also marked SpaceX’s second of 2022, and it has since fired a further two Starlink payloads into orbit, a launch rate that Jonathan Hofeller, the firm’s VP of Starlink and Commercial Sales, can only see accelerating in future.

“We have well over 100,000 subscribers, both on the consumer and enterprise sides,” Hofeller reportedly said in a panel discussion at Euroconsult’s annual World Satellite Business Week event in Paris. “And we’re not slowing down. We’re just getting warmed up.”

3D printing flight-ready satellites

Of course, 3D printing isn’t just used to create launchers or thrusters, but in the manufacture of satellites themselves, often as a means of improving their signal-relaying capabilities. Late last year, Fleet Space unveiled plans to launch its ‘Alpha’ 3D printed satellites, devices said to feature the beamforming technology and patented antennas needed, to unlock greater connectivity for IoT applications.

In 2021, Airbus also revealed that it had made progress with its integration of 3D printed parts into Eutelsat’s relay satellites, having fitted more than 500 switch assembly networks and multi-waveguide blocks to-date. At the time, the firm hailed the lead time and cost benefits of adopting 3D printing within their assembly, and said the resulting satellites would boost broadcast services around the globe.

Looking further back, the likes of Thales Alenia Space have previously deployed additive manufacturing in series satellite production as well. When used within the construction of the company’s Spacebus NEO platform to manufacture custom reaction wheel brackets, the technology is said to have enabled them to be consolidated into a single part, while reducing their weight by as much as 30%.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed AlbaPod 2.0 on a vibration table going through pre-flight certification. Photo via Alba Orbital.