Aimed at both kids and adults alike, companies such as 3Doodler and Future Make have been trying to put the power of 3D printing in the hands of the people, developing 3D printing pens that allow users to be their own 3D printer. These 3D pens have come in many different styles with various levels of capability, but I’ve yet to see one like the 3D printing pen that was just developed by a group of students from the University of Tokyo, which was used to create a large-scale and complex architectural structure by hand.

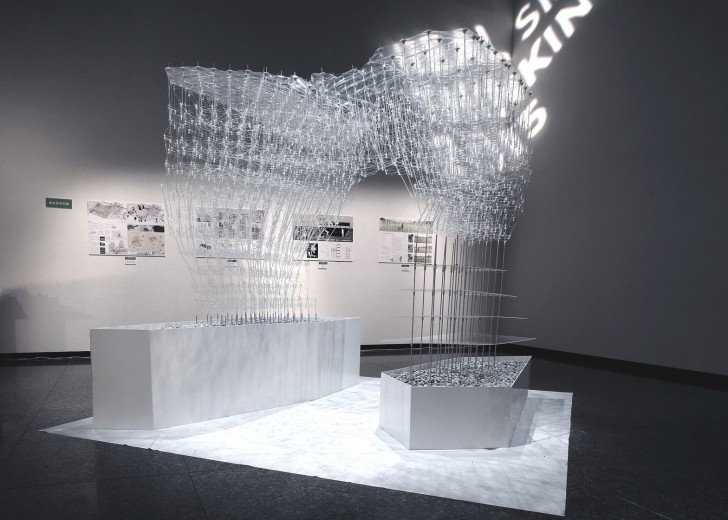

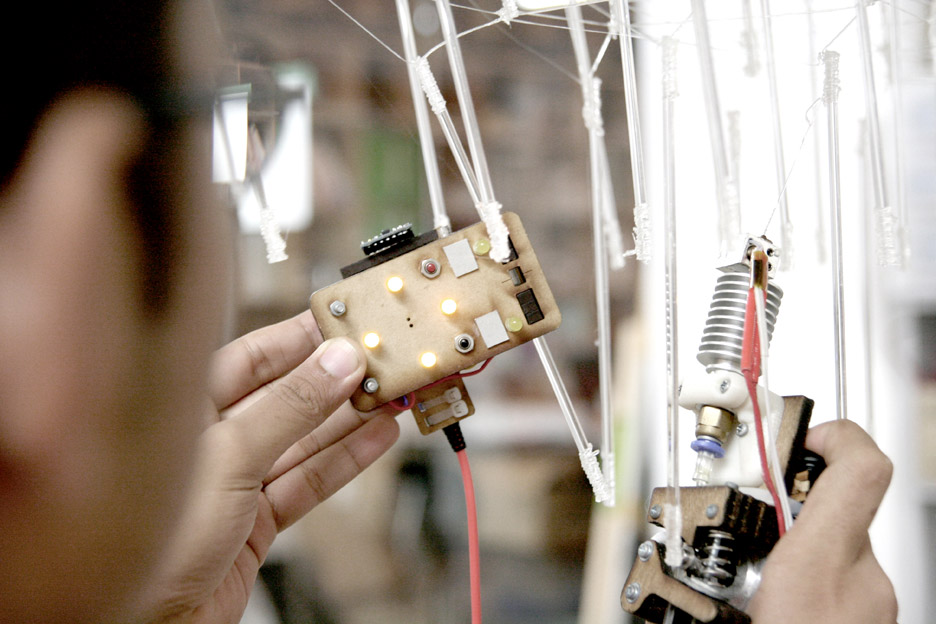

The project, which was overseen by Japanese architect and University of Tokyo professor Kengo Kuma, utilized thermoplastic filament rods that were manually extracted by the students. Though the students were in full control of the 3D printing pen, they were guided by a digital tracking system that kept the planned design intact.

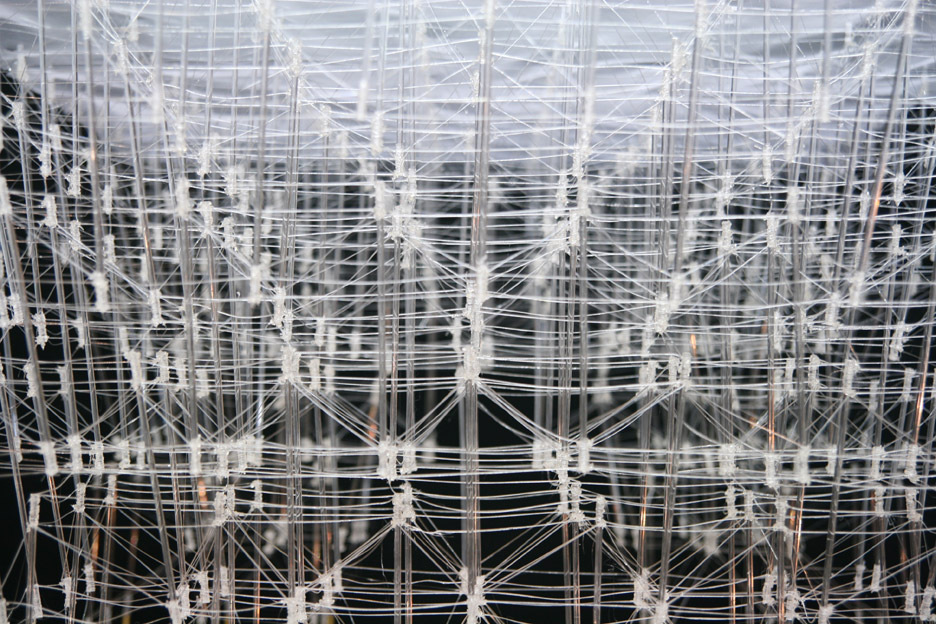

The team of students, whom are a part of the University of Tokyo’s Obuchi Laboratory, followed this digital tracking guide with the 3D printing pen, physically manifesting a digitally designed structure with their very own hands. In order to produce the proper structural stability and strength for the architectural model, the strings bond with acrylic rods, which reportedly creates a structure that is more durable and tension-proof than most traditionally 3D printed objects. What seems to excite these students the most about the 3D printing pen is that it allows for human preference and instinct, which some people, such as the student design team’s Kevin Clement, feel is a crucial part of the digital fabrication process that is missing from 3D printing technology.

“Technology has traditionally been used to automate and replace human labour. The issue with this approach is that it fails to take advantage of human intuition during fabrication,” Clement said. “We believe our approach can bridge the current dichotomy between machine and human-made production.”

This method is also a much more affordable option for large-scale manufacturing, since it doesn’t really have many boundaries as far a volume goes. Large-scale industrial printing is generally too expensive and bulky to be used in on-site construction of structures such as this one, which gives the pen another apparent advantage. These plastic strings are intended to temporarily last about nine months, but can be easily strengthened and structurally reinforced by simply adding more strings to the weaker areas of the model.

And maybe most importantly, the 3D printing pen technology can be utilized by almost anybody, which is exactly the direction the the group of students designers from the University of Tokyo are hoping to go in. The next plan is to open up this fabrication process to the public, allowing visitors to come in and modify and extend the structure themselves.