Desktop 3D printing is still in its infancy, meaning that this young industry has a chance to start things right. Learning from the negative effects of our manufacturing forefathers, we can get 3D printing off the ground with sustainable materials that neither deplete our limited natural resources nor pollute our surrounding ecosystem, crucial to our survival. With that in mind, numerous organizations, Makers, and startups are finding ways to combine recycling with desktop fabrication so that we can simultaneously reduce pollution and dependency on unsustainable materials. The latest to come out of the concrete jungle are TerraCycle and 3DBrooklyn who have announced the development of 3D printing filament made from recycled chip and snack bags.

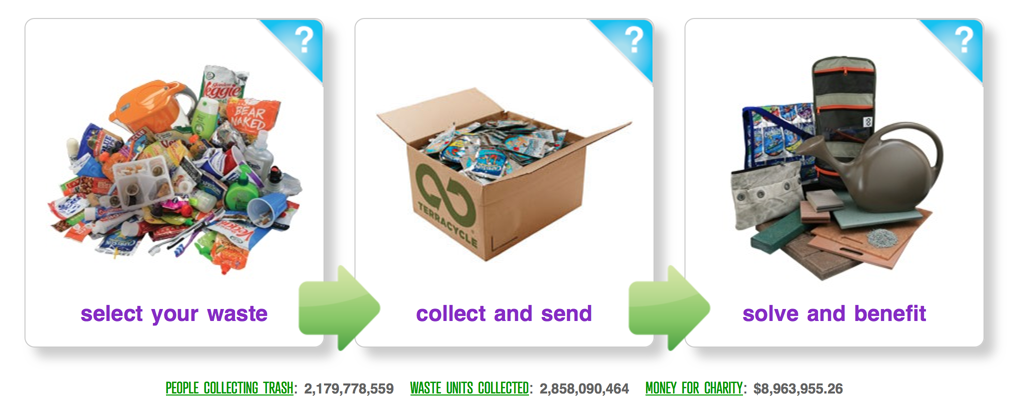

TerryCycle was founded in 2001 to become an international company devoted to recycling typically non-recyclable materials through their free national programs. In turn, the firm is able to convert waste into plastic pellets with which to create plastic products. You can see where this is going! What better use for plastic pellets than to create 3D printing filament? Hence, TerraCycle partnered with 3D Brooklyn to bring their recycling solutions to the world of desktop fabrication.

3DBrooklyn CEO, Nate Kolbeck, says of their partnership, “Using recycled materials to manufacture new products turns a big problem like trash into a solution. With the popularization of desktop manufacturing technologies like 3D printers, more and more people have access to tools that used to be locked behind factory doors. With access comes choice, so more and more people are choosing affordable machines like 3D printers and combining them with sustainable materials like recycled waste and bioplastics. It’s a natural evolution, in a sense, that is turning waste into a resource.”

To give Makers an alternative to the popular petroleum-based plastic ABS, the two firms have produced plastic filaments from post-consumer waste. The first product of their partnership is a recycled plastic filament made from chip and snack bags. Currently sold out on the 3D Brooklyn website, the Recycled Potato Chip Bag Filament represents the beta launch of the product. A polypropylene and polyethylene blend the material has the feel of durable wicker furniture.

TerraCycle CEO, Tom Szaky, adds, “3D printing is the future, and not just for big manufacturing companies, but the technology has already been adopted by schools and individuals. With the industry growing so rapidly, it’s important we provide a recycled alternative to virgin plastic filaments. TerraCycle’s ability to create a recycled plastic filament from post-consumer waste is not only exciting, it’s essential to maintaining a sustainable industry.”

I spoke with TerraCycle publicist Colleen Duncan to learn a little more about the product. Because TerraCycle has experience recycling what is considered typically non-recyclable waste, like chip bags, through national recycling programs they had no problem working with 3D Brooklyn to produce the material. Duncan told me how the process works, “In the case of making 3D filament, we used our collected post-industrial chip bags (which are a pp/pe blend), shredded them down, and extruded them into plastic pellets. We sent these plastic pellets to 3D Brooklyn, who processed the pellets through a filament extruder to create the resulting printing filament.”

Because it has already sold out, it seems promising to me that they might just restock the chip bag filament. There may even be more exciting sustainable filaments on the way. Horray!