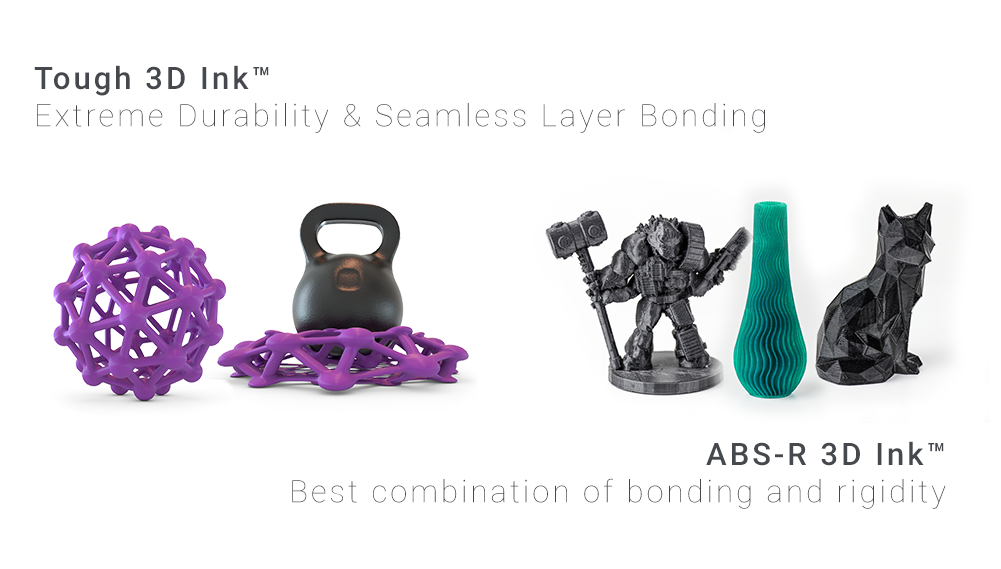

M3D has already become a huge hit with consumers through the release of its compact and affordable Micro 3D printer. Now, the company has begun introducing new filaments to the mix. Today, at CES, the company is announcing the release of its Tough 3D Ink™ and ABS-R™ filaments, which it sees as becoming a new standard for all filament 3D printers.

Tough 3D Ink™ has been engineered for strength, while combining rigid and flexible properties, for users to create practical, functional objects. Bonded at full strength, M3D suggests that this material is odorless and has near zero emissions. Additionally, they say that it doesn’t warm when printed, is capable of withstanding boiling water, and can support several hundred pounds! Tough 3D Ink™ can be print with varying flexibility or rigidity depending on the application. And, with the Micro 3D printer, M3D says that objects can be printed up to 400% faster.

ABS-R™ is meant to be an improvement to standard ABS, with M3D billing the material has having increased bonding and lower warp characteristics. The company also says that it is odorless and doesn’t require a heated bed! At the same time, it produces rigid prints that are somewhat softer in feel than PLA. Altogether, they suggest that ABS-R™ is “more accessible alternative while still offering the same capabilities of ABS.” If true, then M3D could be changing the desktop printing game with this new material, given the issues the world has found with ABS.

Michael Armani, CEO at M3D, says of the announcement, “Often hyped within the context of the digital revolution, people are buying 3D printers to explore this new technology and its creative applications, but they can run into limitations with today’s ABS and PLA as the standard printing material. Seeing all the benefits of Tough 3D Ink™ in our test groups suggests that it will be favored over traditional materials across nearly all applications, and ABS-R™ is set to become a mainstream alternative to traditional ABS filaments. That’s why we’re supporting both materials in early 2016 as our new core filaments for the Micro so that our users can find truly lasting applications.”

To see if these materials live up to expectation, head over to the M3D booth at CES, where you can get your hands on samples of the stuff. Fingers crossed that Tough 3D Ink™ and ABS-R™ perform as well as the Micro, which has received great reviews so far.