Additive manufacturing software developer 3YOURMIND announced a partnership with Werk24, a Munich-based AI and ML company by incorporating Werk24-powered machine-read drawing technology into its software to characterize and meet the criteria of parts for on-demand manufacturing. Werk24-powered technology enables 3YOURMIND customers to analyze technical drawings in four easy steps.

The partnership demonstrates 3YOURMIND’s dedication to expanding its functionalities and assisting customers who need to produce legacy and obsolete spare parts more quickly and conveniently close to where they will be used, says 3YOURMIND.

“We are stoked to work with 3YOURMIND – a company that shares our mission of liberating engineers from reading technical drawings,” says Dr. Jochen Mattes, CEO at Werk24. “Our joint forces allow us to free the AM potential previously imprisoned in drawings.”

What does the partnership bring to the table?

The collaboration between Werk24 and 3YOURMIND demonstrates the increasing need for manufacturing industries to evaluate the existing part inventories for additive manufacturing use cases. With this feature, AM experts and engineers can spend less time performing manual part evaluations and more time on activities that require critical expertise, such as new part design. This integration can help engineers save 5 to 8 minutes per simple part and up to 45 minutes per complex part.

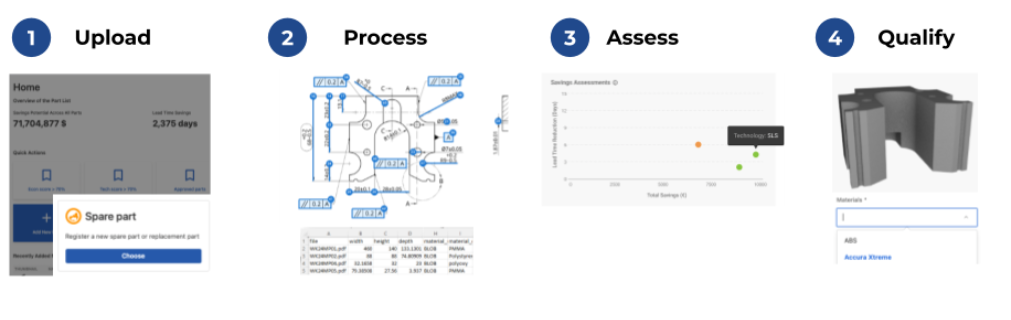

Werk24’s integration analyses 2D technical drawings for 3D printability and lessens data entry time by automatically attaching 3D-suitable parts to customers’ digital inventory. Engineers can choose the most suitable use cases to further assess part information and finalize technical assessments after they have been diagnosed and sorted by printability.

Furthermore, the new integration allows 3YOURMIND customers to analyze parts that already have 3D models. Consumers can simply compare data from technical drawings to decide whether 3D-printed parts meet or improve part performance with this capability.

“We are thrilled to accelerate part digitization for on-demand manufacturing with more AI technology developed by Werk24,” says Stephan Galozy, Senior Vice President of Product at 3YOURMIND. “With this capability, our customers will quickly develop digital inventories of qualified parts for on-demand manufacturing, enabling them to save time and money on a much larger scale.”

2D technical drawings for additive manufacturing applications

Previously, ZVerse, an engineering software provider, introduced its ‘2D to 3D’ CAD file conversion platform. The automated software works to transform outdated 2D part drawings into usable 3D files for use in digital production processes like 3D printing. It is primarily targeted at manufacturers in the maintenance, repair, and operations (MRO) sector. This 2D to 3D platform eliminates the need for time-consuming manual data transfer and is ultimately intended to streamline manufacturing projects with advantages in terms of speed, scale, and cost.

Spare parts with additive manufacturing

Turning to the bigger picture of harnessing 3D printing for spare parts, the French Defense Innovation Agency (DIA) and the University for Research in Automated Production (LURPA) of the École Normale Supérieure Paris-Saclay had joined forces on a joint research and development project with the French software start-up Spare Parts 3D (SP3D). The project, known as “RAPID,” used SP3D’s exclusive DigiPart platform to develop software that can automatically reconstruct 2D drawings into printable 3D models.

Toyota, the Japan-based automotive manufacturer, had previously started collaborating with SOLIZE to 3D print spare parts on demand. Toyota created stock parts using HP Multi Jet Fusion 3D printing as part of a project that began last year and then sold them alongside conventionally manufactured spares. Using the technology is said to enable the company to improve the short-run production capabilities and optimize the designs and lead times of newly developed parts.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows 3YOURMIND CEOs and co-founders Aleksander Ciszek and Stephan Kühr with Bas de Jong, new COO. Image via 3YOURMIND.