Just as the technology behind television was invented by different individuals around the world simultaneously, the unfolding of 3D printed sugar proves that humanity has no main characters, but, instead, blossoms organically with ideas sprouting across the collective. 3D Systems’ ChefJet, in the news for its beautifully ornate printed pieces, was originally developed by a pair of architects based in LA calling themselves the Sugar Lab. At the same time that they were working out their printing process, however, there was a man in the Netherlands who was making his very own 3D sugar printing device.

The sugar printing experiment began with Julian Sing’s love of laser cutting. Sing, a Dutch designer, had been using his laser cutter for years, creating a variety of plywood objects for gifts. After exhausting the possibilities of plywood, he moved onto laser cutting fruits and veggies, demonstrating a fondness for marrying food with technology. And it was during this experimentation that Sing realized that he could apply his laser cutter to sugar, effectively producing a selective laser sintering device for his kitchen. In a blog entry dated October 4, 2011, the inventor explains:

The process uses the heat generated in the laser beam to semi-melt the sugar crystals which are then fused together as it cools. After a single pass on the laser I lowered the Z axis of the laser cutter, threw in a bit more sugar and hit “Go” once again. I repeated this process 4 times and in the end it created this 5mm thick ring made from just sugar. And the best part I didn’t even mention yet. While the laser is melting the sugar it smells just like Fairy Floss, oh yum.

How cool is that!?

Sing elaborated on his sugar designs, getting more adventurous with each project. Eventually, he went from printing heart rings and posting about it on his Muzoo Design blog to launching a site entirely devoted to sugar printing and working on more and more elaborate prints. With plans of being able to create cake toppers, Sing posts about his successes, such as this sugar bowl printed in sugar:

And his failures, such as this thing – whatever it is:

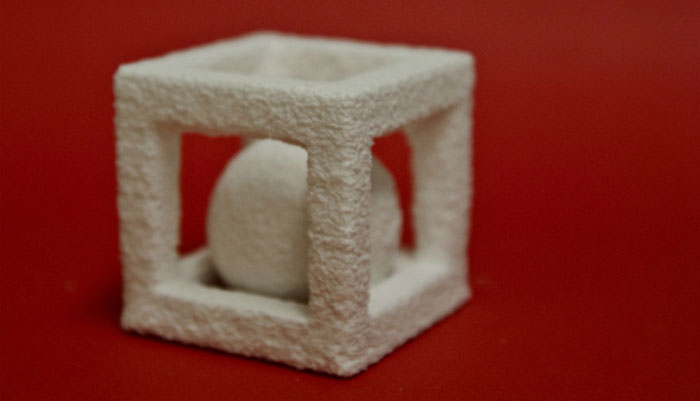

By 2014, Sing had developed his own sugar based powder and binding agent and – with the help of food scientists, chemists, and engineers – had himself a system for printing sugar objects almost as intricate as those from Sugar Labs. Calling himself the 3D Chef, one wonders how aware of the Sugar Labs/3D Systems technology he is. He even printed one of these, which I’ve seen at more than a couple 3D Systems expo booths:

Most recently, Sing posted this meshed egg, which he was able to print three times to prove his machine’s repeatability:

Now that the designer knows that he’s capable of creating cake toppers, I wonder if Sing will follow in the footsteps of Sugar Labs. You know: sell custom, 3D-printed cake toppers, get a lot of press, and then get bought out by 3D Systems.

Source: 3D Chef