There are plenty of case studies that point to a marriage of convenience between 3D printing and the discipline of architecture — both for modelling and construction. However the breadth and depth of the continued evolution of 3D printing technologies also continues to open up new application possibilities within the architectuaral arena. This is highlighted by the work of architect Philippe Morel from Studio EZCT Architecture & Design Research in Paris, who is using 3D printed sand moulds produced by voxeljet for his research with ultra high-strength concrete.

Ultra-high performance concrete or more usually the acronym UHPC is generating a revolution in architecture by all accounts. . UHPC is concrete that has been reinforced with specific fibres that make it six to eight times stronger than conventional concrete while also making it much lighter and denser in structure. And, as if that weren’t advantage enough, UPC also provides excellent material quality without pores and micro tears.

Quite unsurprising, then, that architects are keen to experiment with this material. The research activities of the EZCT focuses on UHPC and the search for lighter and filigree concrete structures that will provide a completely new level of design freedom in architecture for the future. Philippe says of the research: “We needed a quicker and more cost-effective process for manufacturing moulds for UHPC casting. At this time, the only economic alternative for our research work is to print sand moulds on the fast voxeljet machines using 3D printing.”

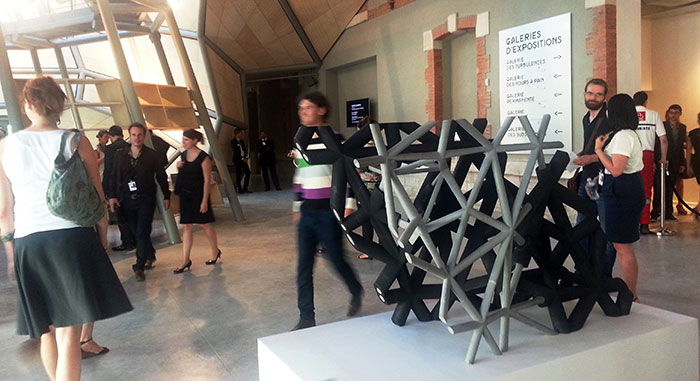

The research is ongoing but one spectacular example of the EZCT’s work with UHPC can be found at the architecture trade fair in the FRAC Centre in Orléans until the end of March. For this project, voxeljet printed a total of 130 sand mould halves for the concrete cast. After printing, the inside and outside of the various halves were infiltrated with epoxy resin and were subsequently glued together in order to achieve a very fine concrete structure. This process was followed by casting using UHPC, and the assembly of the individual parts.

Philippe subsequently only partially removed the sand moulds from the part to demonstrate how the complex UHPC structure was created. Morel believes that the direct 3D printing of parts made of UHPC and bypassing the use of sand moulds altogether will be the actual production method of the future. To turn this vision into reality, voxeljet’s development departments has already been studying the 3D printing of concrete materials.

Can’t wait to see how that turns out!

Image Credit. All images courtesey of EZCT ©.