This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

Przemek Jaworski is the founder and CEO of ZMorph, a leading manufacturer of multitool 3D printers that combine 3D printing, CNC milling, laser engraving, and thick paste extrusion within one desktop machine. Jaworski is also an architect and designer devoted to developing new tools that will enable creative professionals to fully materialize their ideas.

3D Printing The Next Five Years by Przemek Jaworski, Founder and CEO of ZMorph

5 years seems like a long time but when you look back – it often feels like some events, discoveries, or trends happened just a moment ago. 5 years ago I was still working as an architect and designer, looking for a desktop tool that would enable me to use various fabrication methods in rapid prototyping. There were none at the time, desktop 3D printing in general was a fairly new deal, and that’s when the idea to build a ZMorph machine came to my mind.

A lot has changed since then as I managed not only to build a machine for me but launched a company that makes multitool 3D printers that are now available all around the globe. Based on this experience I hope to predict a few things that we can all look forward to in the next 5 years. Especially in desktop 3D printing, which is naturally my main point of interest.

Multi-material 3D printing will become more popular

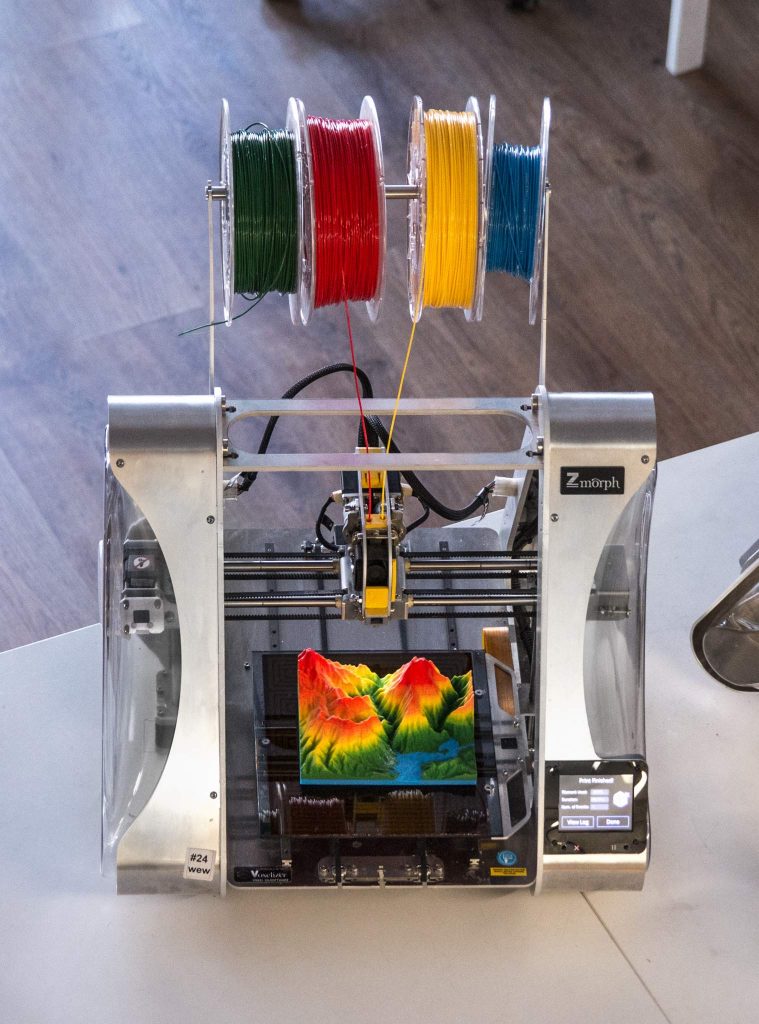

I have no doubt that multi-material 3D printing technology of Fused Filament Fabrication will continue to grow in coming years. It’s the least expensive method of 3D printing, and it offers vast material base, that keeps expanding every year. The quality it offers is not considered to be the best, in comparison to high-end resin or powder printers, but this will keep changing too. I believe many of these challenges will be won by using advanced software, which can be a game-changer, despite technological limitations.

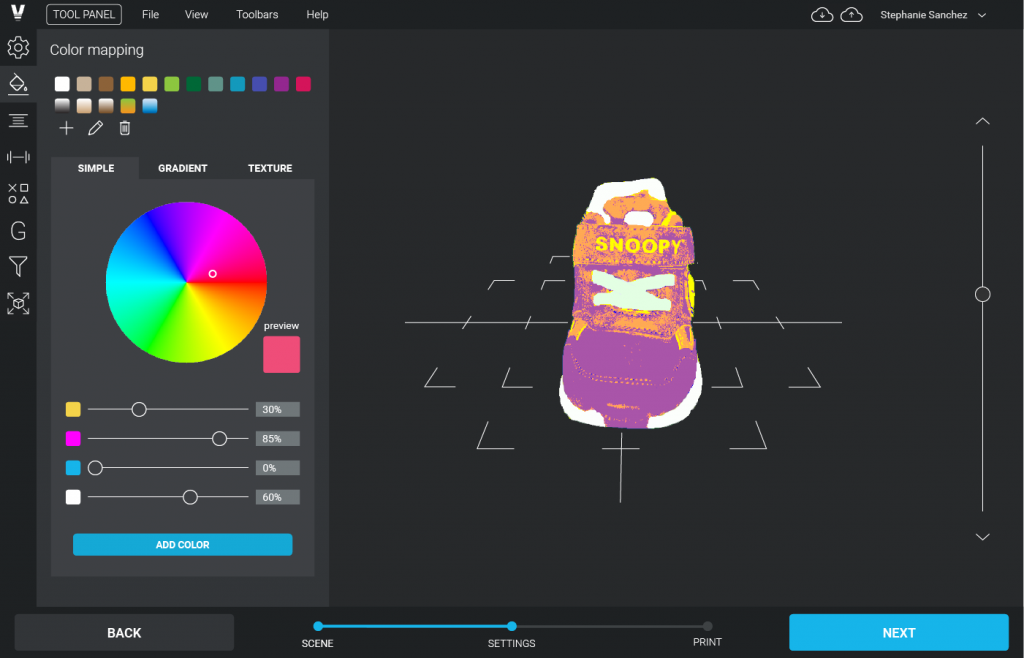

At ZMorph we’re experimenting with this a lot. Recent updates to the Voxelizer software allowed our two-material DUAL PRO extruder not only to blend filaments but also print colorful images on 3D objects, which we call Image Mapping. It gave our existing users a completely new functionality and provided a competitive advantage for attracting new clients.

Another upcoming feature is a set of special tools and 3D filters for architectural models production – totally relying on clever algorithms for no-support printing of floorplates for example.

Therefore I believe that new dedicated software is a factor that can’t be ignored – and will be crucial for pushing the limits of 3D printing, as the hardware in most machines offers similar technical capabilities and is not progressing much more.

So, in general, the greatest potential for growth in desktop 3D printing for coming years is multi-materiality. Why?

Multi-materiality, multitool, and more

First of all, multi-materiality opens new possibilities in rapid prototyping, which still is the most common application of 3D printing. Although it’s already possible to combine materials in two-material extruders or experimental four-material ones, we’re still a few steps before the quality reaches its full potential (also thanks to a dedicated software).

Multi-materiality in desktop 3D printing will thrive once it enables a truly high-quality material blending of various filaments. Creating prototypes that include hard and flexible parts within one print is possible with expensive industrial machines. As it becomes achievable with a desktop 3D printer, the technology gets more accessible and affordable to a greater number of professionals and unlocks their creative powers.

Color blending and full-color FFF / FDM desktop 3D printing will also improve and become an industry standard. This will only broaden the possibilities and enable new professional applications.

Aside from rapid prototyping, I think that desktop 3D printing in the next 5 years will find new applications in manufacturing market-ready parts and whole market-ready products. With new kinds of conductive and nonconductive materials, it will be possible for example to print working drones and robots. Multitool machine with additional toolheads could even be able to place working electronics in them!

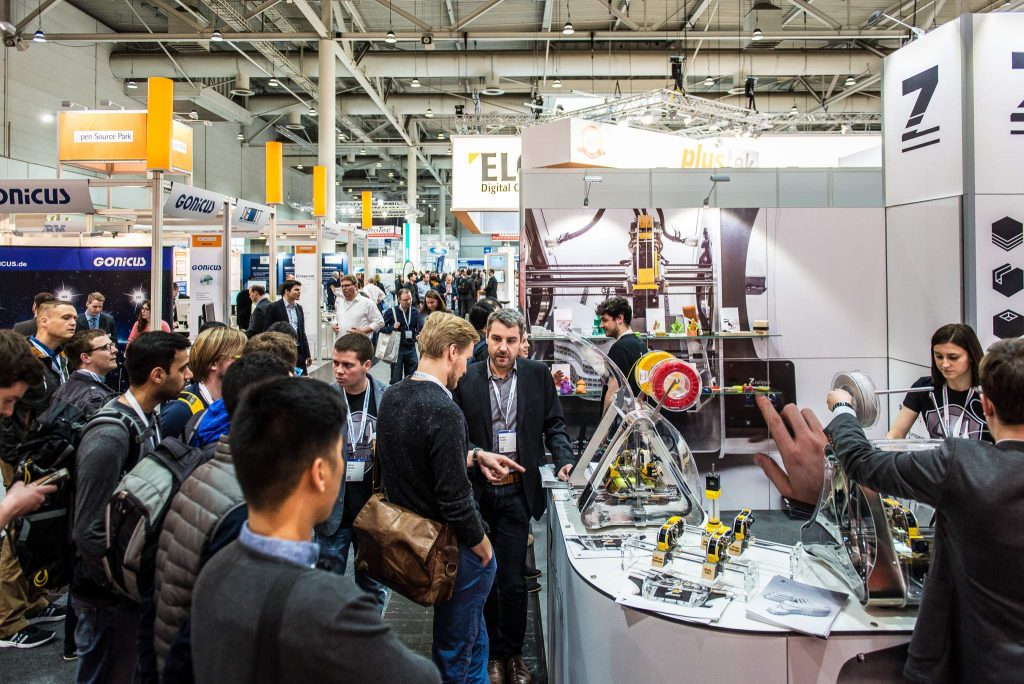

This is why the future will bring us more and more multitool solutions and interchangeable functional modules for existing machines. I’m meeting a lot of people who already have a huge experience with 3D printing and want to expand beyond that. By adding CNC or laser into their workflows, they can enhance their multi-material capabilities even further, just like I did a few years back. This opens up lots of applications in the field of robotics and production of intelligent machines.

To sum up, I’m pretty sure that in the next 5 years we will see a lot of new multifunctional desktop fabrication tools, able to make objects from many materials at once. They will be used to make other machines, robots, vehicles, drones, or maybe even functional clones of themselves. There is much more to 3D printing, and my personal goal is to make sure that ZMorph multitool 3D printer is part of the avant-garde in this process.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels.

Don’t forget that you can vote now in the 1st annual 3D Printing Industry Awards.

More information about ZMorph is available here.

#futureof3Dprinting

Featured image shows Zmorph CEO Przemek Jaworski. Photo via ZMorph.