This edition of our 3D printing news digest Sliced asks the following questions: Is advanced manufacturing destined to destroy jobs? Will 3D printing benefit from trade wars between the US, Europe and China? How is bioprinting advancing and what are the latest career moves and opportunities across the 3D printing industry?

Also, 3D printing news from Siemens, Stratasys. ExOne, Massivit, Laser Lines, CELLINK, Formlabs and other enterprises in the additive manufacturing sector.

3D printing and trade wars

Professor Joshua M. Pearce, of the Materials Science and Engineering dept at Michigan Technological University has written an in depth analysis of how the looming trade war between the US, China, and Europe could impact the use of 3D printing.

Writing in EconTimes, Prof. Pearce discusses that barriers to trade such as tariffs could turn out to be of benefit to the proliferation of additive manufacturing. The argument runs that onshoring production due to more expensive imports may be aided by localised manufacturing, for example using 3D printing.

Past research by Prof. Pearce and his group has shown how to make money from 3D printing and also identified cost savings available to consumers.

The digital manufacturing expert concludes, “The trade war may drive manufacturing back to the United States – just not in the way [Donald Trump] predicted,” concludes Prof. Pearce.

3D Printing Industry asked experts for their perspective on how the trade war will affect 3D printing, read the responses now. Let us know your thoughts on this topic.

Fourth industrial revolution may “decimate” jobs

In a recent interview the President and CEO of Siemens Joe Kaeser, makes a gloomy prediction for the future, unless action is taken.

Calling the fourth industrial revolution “one of the single most important transformations of all time” Kaeser went on to say, “It may cause quite a dip in employment, because if you have 20-30 less value chain, then … you have 20%-30% fewer jobs. That is how it has been in the first three industrial revolutions.”

To avoid mass unemployment, Kaeser advocates for adapting and educating the current workforce. Reskilling and retraining are likely to become common features throughout an adults career. The Siemens CEO points to recent investments in advanced facilities, such as the £27m 3D printing site in the UK, as exemplars of this philosophy.

“The social and economic impact of digitalization is going to be massive. The least efficient part of the value chain, the middle man, will be cut out. Unfortunately, the least efficient part of the value chain is human beings so someone has to do something about the fallout.”

The TRIWA Humanium watch initiative

TRIWA, a Stockholm-based watch manufacturer, is collaborating with Humanium by IM, an enterprise distributing metal made from decommissioned firearms. This partnership is helping TRIWA produce a new line of watches that will promote the end of gun violence.

So far 10,000 guns have been melted down and will be processed into the new line of TRIWA Humanium metal watches, which will also use additive manufacturing processes to create its components.

“To destroy a gun, you first saw it apart and melt it down. The metal that results in about 95% iron,” said Ludvig Scheja, Co-founder of TRIWA.

Starting in September 2018, the watches will be priced from $279 and are available for preorder on TRIWA’s Kickstarter.

The first 3D printed wine vessels

QvevriXYZ, manufacturers of qvevris, an egg-shaped earthenware vessel used for making, ageing and storing wine, based in the Eastern European country, Georgia, have produced the first 3D printed qvevri.

According to QvevriXYZ, the composition of clay is vital when making a qvevri as it gradually infuses with the wine, giving it a distinctive taste. Thus, QvevriXYZ visited the Georgian village, Shrosha, known for its clayworks, to develop an automated system that produces qvevris ranging from 50 to 1000 liters.

“Primitive methods of production [means that] today, qvevri are inaccessible and of poor or inconsistent quality,” stated the QvevriXYZ team. “Using elements of the traditional qvevri-making process and modern technologies, we improved its structure and quality, yet kept its unique characteristics.”

3D printed life-size replica of an Italian car

Colorzenith, an Italy-based large format 3D printing service bureau, has 3D printed a life-size replica of the classic Italian car, Lancia B24 to be used as a set design piece in the Don Pasquale opera, performed in the La Scala opera house in Milan.

The car needed to be lightweight for as it will descend from the ceiling to the stage with the performers inside. Using a Massivit 1800 3D Printer, Colorzenith produced the car replica in under four days. It measures at 4.23 metres in length and 1.3 metres in height(13.88ft x 4.27ft).

“Massivit 3D printing was the perfect solution to produce a lightweight replica of the car. Considering the tight production time frame, it was impossible to realize this with another technology,” said Florian Boje, Founder of GIÒ FORMA, responsible for the stage design of the Don Pasquale opera.

The car was then sanded and strengthened with an internal metal frame. Set designers also glued headlights, mudguards and door handles to the car to create a more realistic appearance.

In other news, Brett Turnage, racing fanatic and ambassador for the 3D printing community marketplace Pinshape, has released two new 3D printed RC cars of the Mazda 787B and the McLaren Mp4/6.

The WSSU occupational therapy project

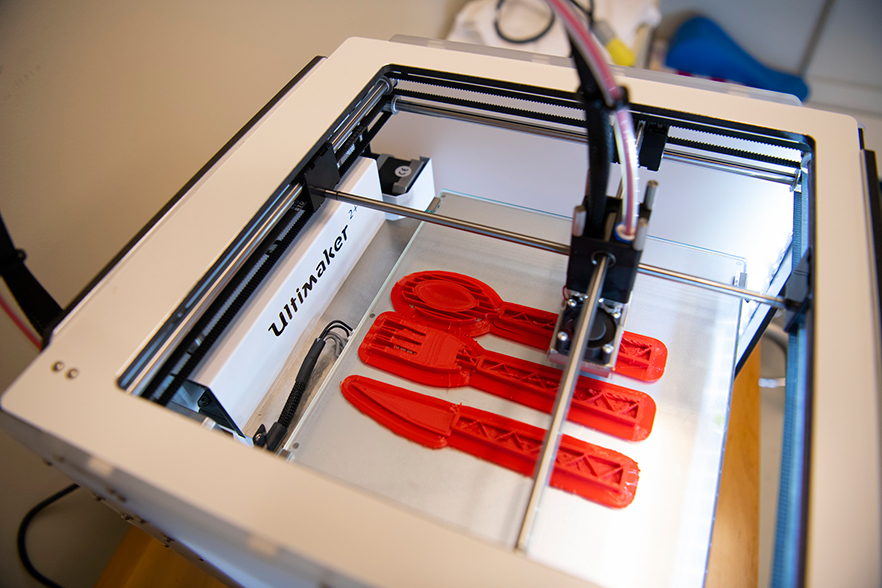

The Occupational Therapy Department at Winston-Salem State University (WSSU) is examining 3D printing through a new summer curriculum project.

“There are huge implications for the use of 3D printing technology in occupational therapy practice,” said Elizabeth Fain, Assistant Professor of Occupational Tharp at WSSU.

“This emerging technology can produce equipment, tools, and prosthetics that are customizable and at a much lower cost. Therefore, exposing the next generation of OT practitioners to its potential application is crucial and is an emerging technology that is not being offered at many OT programs.”

Thus far, Fain and Diego Herrera, a graduate student in WSSU’s occupational therapy program, have produced tools such as pill bottle openers, eating utensils, and button hooks using an Ultimaker 3D printer.

The equipment produced from this project will be given to patients at the program’s Occupational Therapy Clinic, based at the Community Care Center of Forsyth County.

The long-term goal of this project is to begin printing prosthetics that can be offered to uninsured residents.

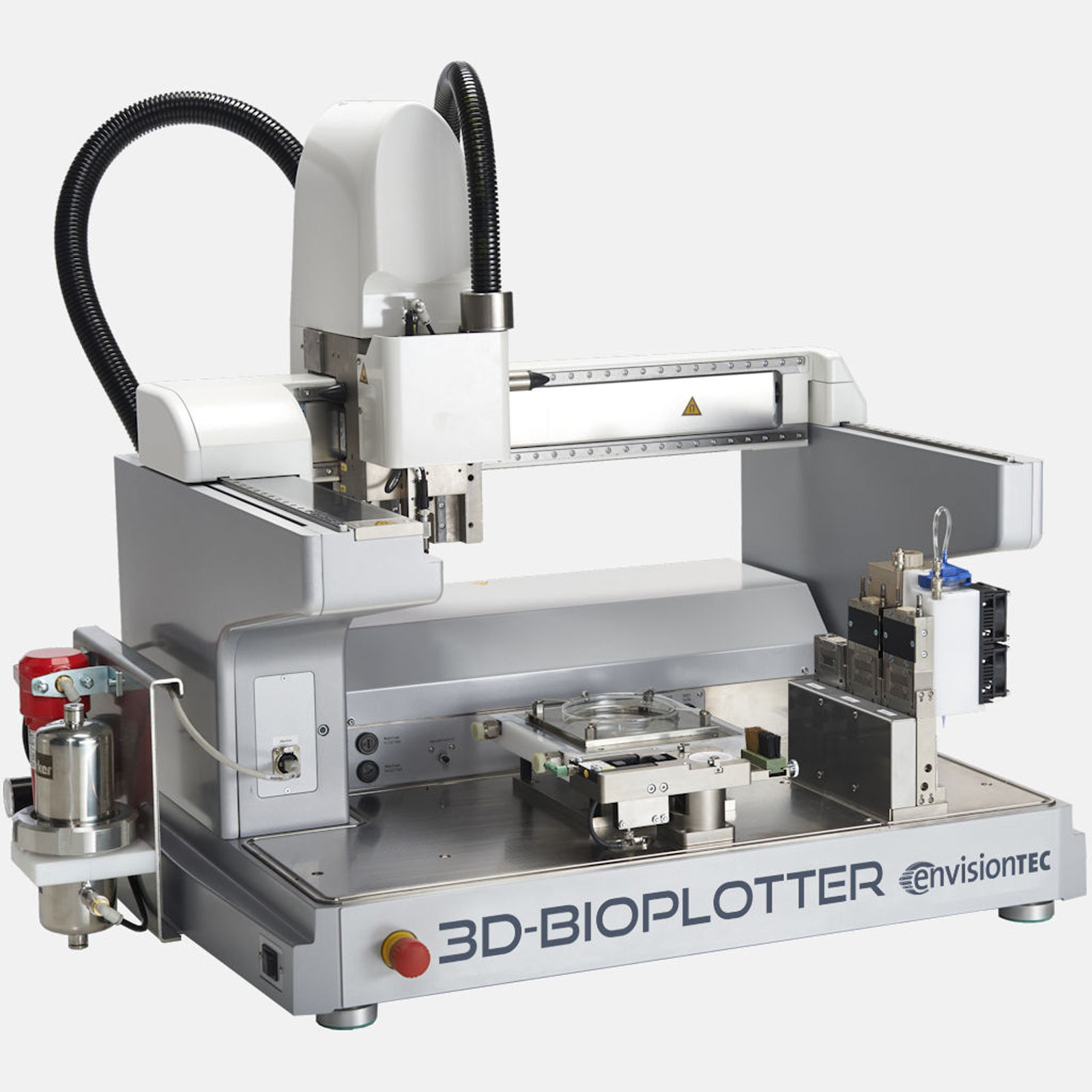

Advancing 3D bioprinting

CELLINK, a 3D bioprinting startup based in Sweden, has received an EU grant of €2.5 million for the development and commercialization of its TumorPrint project.

The TumorPrint project will offer pharmaceutical companies a screening platform including, bioinks, software, and hardware specialized for the fabrication of 3D printed human cancer tumors. This will allow them to study cell reaction within cancer tumors when exposed to different compounds.

If successful, the 29-month-long project will generate income to CELLINK through sales of Bioinks, software, and systems.

Furthermore, the Carl R. Woese Institute for Genomic Biology (IGB) at the University of Illinois Urbana has purchased an EnvisionTEC 3D-Bioplotter, an open-source biomaterials 3D printer, to conduct regenerative biology and tissue engineering research.

Strategic leadership shifts & a new Formlabs distributor

Star Rapid, a Hong Kong 3D printing bureau, has announced, David Hunter, a Business Transformation Specialist as its new CEO.

ExOne, a U.S. based industrial 3D printer manufacturer, has announced Brian W. Smith as its new Senior Vice President and Douglas D. Zemba as Chief Financial Officer and Treasurer.

Formlabs, desktop SLA 3D printer manufacturers based in Massachusetts, has announced its new distributor, Laser Lines, a 3D printer reseller from Banbury, UK.

Looking to hire additive manufacturing experts or a new position in the 3D printing industry? Join our free 3D printer jobs service now.

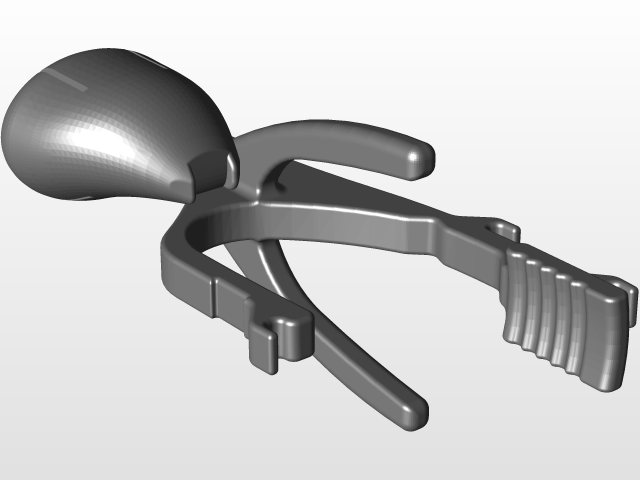

Students create 3D printed device to help Veteran play video games

SME and Stratasys have announced the winners of the SkillsUSA annual additive manufacturing student competition, in Louisville, Kentucky.

44 teams of secondary and tertiary level students faced the task of designing and producing a 3D printed adaptive device for a veteran who endured a thumb amputation on his left hand. This device was designed to allow the veteran use of a PlayStation 3 controller, as gaming is his favorite pastime.

Students from the Central Community College-Hastings, Nebraska and Martin Luther King High School, California received gold medals for their devices which allowed the veteran to comfortably use a PlayStation 3 controller, without his current silicone prosthetic.

“The SkillsUSA Additive Manufacturing Competition allows students to explore and apply promising emerging additive technologies that are increasingly used in manufacturing operations,” said Jeff Krause, Executive Director and CEO of SME.

“SME and Stratasys have built a competition that is inspiring and attracting tomorrow’s manufacturing workforce.”

Furthermore, the Saudi International Petrochemical Company (Sipchem) has launched the Sipchem Innovation Club which will teach children aged 8-12 about new technologies. This includes artificial intelligence (AI), programming, 3D printing, and robotics.

Techniplas’ Sharebot Deployment & funding for 3DomFuel

Techniplas, a Wisconsin-based manufacturing provider of automotive products and services, has completed the deployment of Sharebot 3D printers within its 14 manufacturing facilities.

This integration follows a tooling production partnership between Techniplas and Sharebot which sought to reduce Techniplas’ cost of production and development time for parts used on vehicle assembly lines.

“Based on our experience with Sharebot printers thus far, we expect to significantly reduce our development time and annual assembly line tooling costs in each manufacturing facility over time,” said Manfred Kwade, Chief Operating Officer of Techniplas.

Finally, a funding program within the North Dakota Department of Commerce has awarded capital for 11 primary-sector businesses totaling $1,469,000. This includes 3DomFuel, a filament manufacturer based in Fargo, North Dakota.

Stay ahead and read the latest 3D printing news. Subscribe to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows Sliced logo over 3D printed qvevris. Photo via QvevriXYZ.