In a design-heavy week for the industry, today’s Sliced 3D printing digest covers stories from: Adi Meyer Architects, Jack Elliott, Dinara Kasko, TU Eindhoven, BAM Infrastructure, Jiangnan University, the Irish Science Foundation, Luleå University of Technology, the University of Tromsø, the University of Oulu, MakePrintable, ANSYS, Stratasys, Lockheed Martin, PADT, EOS, LPW Technology and Additive Industries.

Intuitive face masks, impossible cakes and the Netherlands’ bicycle bridge

Using Harvard’s Soft Robotics Toolkit, Adi Meyer Architects have 3D printed a conceptual face mask that reacts to a person’s emotions.

Artist Jack Elliott makes a statement about the forestry industry by scanning, and replicating the base of deforested maple tree, now on display at Cornell University.

Former architect Dinara Kasko has turned a keen eye for design into making molds for geometric, and structurally impressive cakes. The molds are made using a 3D printer, and are capable of creating “impossible” bubble, and origami inspired treats.

Eindhoven University of Technology (TU Eindhoven) and BAM Infrastructure’s 3D printed concrete bicycle bridge is now under installation in Gemert, The Netherlands. Once in place, the bridge will span 8 meters x 3.5 meters (L x W) across a narrow stream.

Development of 3D printing research excellence in China, North America, Ireland and the Nordics

Lemon and potato extracts combine in the latest 3D printer materials research from a collaboration between Jiangnan University, China, the University of Queensland, Australia and Guangdong Galore Food Co. The supporting paper has been published online in the journal LWT – Food Science and Technology.

Adding to an existing partnership with Lockheed Martin and Phoenix Analysis & Design Technologies (PADT), Stratasys are launching a defence-oriented Additive Manufacturing Laboratory at Metropolitan State University, Denver.

With a €74m investment from the government and further €40m from industry partners, Taoiseach Leo Varadkar and Tánaiste Frances Fitzgerald are launching four new scientific research centers in Ireland. The centers, under development over the next six years are part of the nation’s Science Foundation, focusing on excellence in cutting edge technologies such as robotics and 3D printing.

In a more specific project in the Nordics, Luleå University of Technology, Sweden, the University of Tromsø, Norway and the University of Oulu, Finland, are teaming up with 15 industrial partners to develop a new method of metal 3D printing.

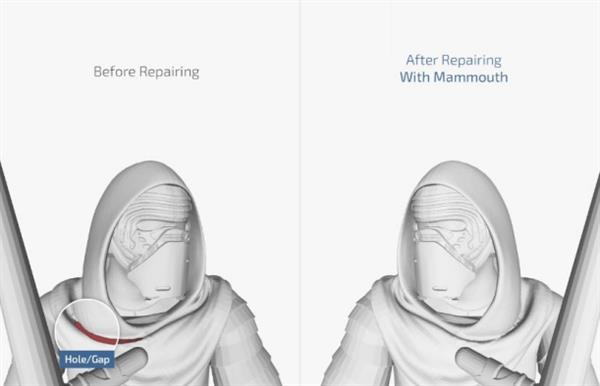

Mammoth software updates

Teased in March 2017, cloud-based model fixing software MakePrintable has launched its Mammoth technology for high-speed .stl mesh repair.

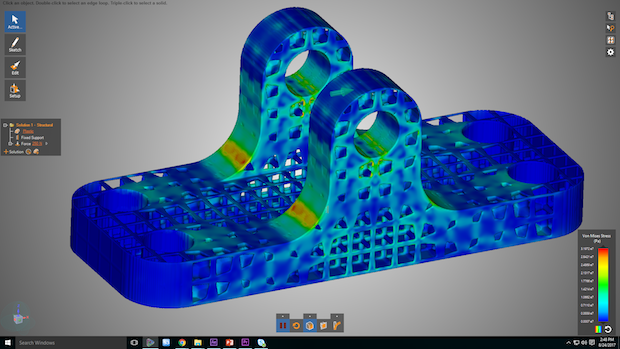

Simulation and CAD specialist ANSYS has launched the Discovery Live feature, giving users the ability to instantly visualize complex 3D component designs. Mark Hindsbo, vice president and general manager at ANSYS comments, “Discovery Live’s breakthrough technology places real-time simulation in the hands of every engineer. Coupled with an equal step change in ease of use, it enables true digital experimentation.”

“This will fundamentally change product development, inverting the traditional process by bringing simulation upfront and enabling millions of engineers to benefit from the power of simulation.”

EOS, LPW and Additive Industries

Industrial 3D printing solutions provider EOS has released a new stainless steel powder for its M 290 system. As with the forthcoming P 500 polymer system, the development contributes to the firm’s serial scalability plans.

Dr. Tobias Abeln, EOS CTO, comments, “Planning security and reliability are top priorities for customers who are engaged in serial manufacturing. For its StainlessSteel 17-4PH IndustryLine, EOS provides reliable and statistically proven data for the most important material properties of finished parts.”

“This significantly raises quality standards in Additive Manufacturing. The customer can use the data 1:1 to qualify the technology for large-scale production and therefore minimize the time required as well as cut the cost of in-house material and process qualification.”

Implant manufacturer Exactech has announced that it will be using LPW Technology’s PowderSolve quality control technology to verify metal 3D printed bone replacements.

Dr. Mark Beard, a materials scientist and graduate of the University of Exeter in the UK has joined Netherlands-based Additive Industries as the new head Process & Application Development. The firm’s proprietary MetalFAB1 system will also be on display at the IAA automotive show in Frankfurt, 12 -17 September 2017.

Never miss a story – sign up to the free 3D Printing Industry newsletter, and check out more news on Facebook and Twitter.

Register your research expertise on our 3D printing jobs site here.

Featured image: Sliced logo over a cake made using Dinara Kasko’s 3D printed cake molds. Original photo by Dinara Kasko