Today’s edition of our 3D printing news digest Sliced, asks the following: How do you redirect sound with 3D printing? Will 3D printers ever find a place in mechanics’ shops? Are 3D printed hypersonic warheads viable? All this and more from Duke University, PostNord, GKN Powder Metallurgy and the 3MF consortium.

Metamaterials, soluble supports and more

Researchers at Duke University, Carolina, have used 3D printing to create a device that can control and redirect soundwaves almost perfectly. The device is made from a kind of metamaterial, which controls and redirects sound through its structure, rather than through their chemical composition. Researchers say the device has applications for sonar technology.

“Systematic design and experimental demonstration of bianisotropic metasurfaces for scattering-free manipulation of acoustic wavefronts” is available to read in the Nature Communications journal.

Researchers at Nanyang Technological University have enhanced the strength and ductility of 316L stainless steel, by using selective laser melting. They achieved improvements by in-process engineering of the steel’s crystallographic texture. The paper titled “Simultaneously enhanced strength and ductility for 3D-printed stainless steel 316L by selective laser melting” is published in the NPG Asia Materials journal.

Airwolf 3D’s patent-pending HydroFill Water-Soluble Support has been reformulated to improve the quality and performance of the material.

PostNord partners with 3YOURMIND

PostNord Strålfors, a communications solutions provider in Denmark, which recently added an on-demand 3D printing delivery service, has partnered with 3YOURMIND to use their software platforms to optimize the new service.

Scanning arteries with light

Researchers at Aalto University, Finland, are using super-hydrophobic interfaces to create hollow structures in bacterial cellulose. The technique has been outlined in a paper published in the Materials Horizons journal.

Proslab, a dental laboratory in Australia, has digitized the manufacture of cobalt chrome removable partial dentures, using Renishaw metal 3D printers. Designed in CAD, the dentures were printed in resin before being produced in cobalt chrome with traditional lost-wax casting.

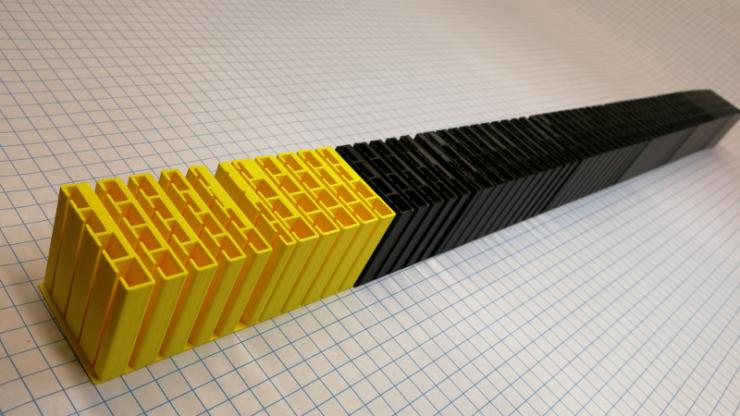

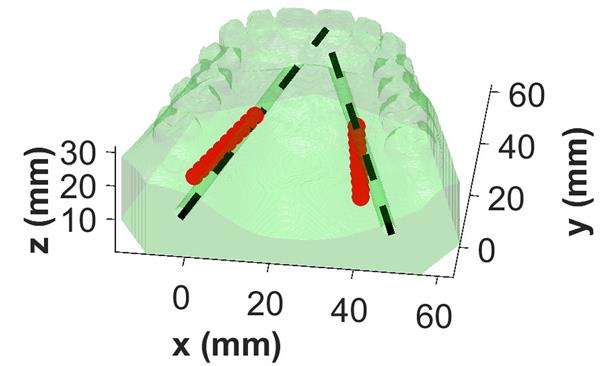

Starfish Engineering LLC, a startup associated with Purdue University, Indiana, U.S., has built a medical imaging device that uses light to create a detailed picture of arteries in the roof of the mouth. Starfish Engineering has used 3D printing to build replicas of patients’ mouths with accurately placed arteries.

Hypersonic warheads and the future of the local mechanics’ shop

A partially 3D printed warhead for hypersonic weapons, which travel five times faster than sound, is being tested in a facility in Burnet, Texas. Created by Orbital ATK for the U.S. Department of Defense, three out of five major components have been fabricated on 3D printers.

Orbital ATK Program manager, Richard Truitt said,

“We are really happy to do this test with additive manufactured parts because it’s going to tell us, does that actually function the way a normal component would.”

Markus Josten, Global Sales Director at GKN Powder Metallurgy, a producer of sintered components and metal powders for 3D printing, has speculated that in the next 10 to 20 years, 3D printing will be a common sight in local mechanics’ shops. In a GKN Sinter Metals Blog post, Josten has outlined his vision for the growing role of 3D printing in the automotive aftermarket industry.

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) is looking for 3D printers to assist with Data61. Data61 is a data innovation group based in Australia. Data61 is specifically seeking a high-end, multi-material 3D printer to assist with the organisation’s burgeoning soft robotics capabilities.

3MF releases new extension for lattice-type geometry

The 3MF Consortium, has released its new Beam Lattice Specification Extension. The extension provides an entirely new way of storing and transferring lattice-type geometry information. The extension, now available for download, has all the features of the 3MF Core Specification, meaning materials, colors, build information and much more can be found in one compact file.

Keep abreast of the latest 3D printing news. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Advance your career in 3D printing, or post a job. The 3D Printing Jobs board is live.

Vote in the 2018 3D Printing Industry Awards, before it closes.

Featured image shows the testing of a partially 3D printed hypersonic warhead. Photo via Orbital ATK.