Just a few days ago we told you about the Strooder and of the importance of functional filament extruders for the growth and development of the 3D printing consumer industry. For consumer 3D printing to have a beneficial effect on the world as a whole, filament recycling will be key. Recycling plastic is exactly what another filament extruder project is focusing on.

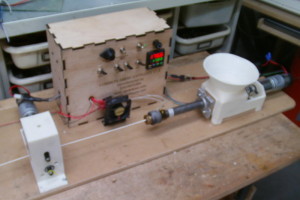

Created by Liz Havlin and soon to go live on Kickstarter, the Legacy Filament Extruder is an example of how an idea can grow, through successive steps, into something bigger and better. The original extruder concept Liz used had been developed and published on Thingiverse by Hugh Lyman, who had won a $40,000 contest with it from the Maker Education Initiative.

She then met with Northwest Center in Seattle, who provided the assembly service while creating new local jobs and developing a working business model. Ironically one of the most difficult parts was getting the 3D printed prototypes. Professional companies charged a fairly hefty price tag for a community based project to afford so the team turned to Luminar Products, a team of engineers, designers, scientists and inventors. The Idaho based company built its own 3D printer for partnering with distributors and manufacturing ventures.

Unfortunately, as nice as the idea is of using the world’s enormous amounts of waste plastic to produce new objects with 3D printing, it’s probably not a surprise that it is not at an easy task. The reality of recycling plastic is a lot more difficult than the “nice concept” because each object needs to be cleaned and separated with the same types of plastic. Extruding it into usable filament is even more complex.

Liz studied the issues and has been able to partner with local plastic companies to trade waste plastics for pellets to pass on to the Legacy Extruder Customers. The premise is that one day you might be able to bring recyclable plastic objects in to trade for credits that may be used to purchase pellets, filament and services at special collection sites throughout the US. The model could also be exported internationally through partnerships with similarly minded organizations such as The Plastic Bank, the Perpetual Plastic Project, the Ethical Filament Foundation or Protoprint. For every five extruders that are pledged, one will be shipped to India, Africa or Haiti to offer opportunities to people in impoverished areas. Recycling people’s abilities is 3D printing at its finest.