In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features multiple 3D printing partnerships, new 3D printing powders and filaments, and a project call for material data optimization, finished off with a sweet 3D printed treat.

Read on for the most recent updates from IAM 3D HUB, Renishaw, InterPRO, Imaginarium, Nanoe, Sugar Lab, and more.

New 3D printing partnerships for GE Additive, Henkel, and IAM 3D Hub

Kicking off this week’s round-up is the announcement that India’s largest rapid prototyping and manufacturing center, Imaginarium, has joined GE Additive’s global sales partner network as an official sales partner in India. Imaginarium will resell GE’s portfolio of metal powders and metal additive manufacturing machines, equipped with GE’s Direct Metal Laser Melting (DMLM) and Electron Beam Melting (EBM) technologies.

Meanwhile, global chemical firm Henkel and additive manufacturing service bureau InterPRO are expanding their collaboration to further the adoption of 3D printing for the production of industrial parts. The firms have already worked together over the past two years to test new materials, onboard new applications, and covert production work to Digital Light Processing (DLP) technologies.

“We are delighted to announce the expansion of our collaboration with InterPRO,” said Dr. Simon Mawson, Senior Vice President and Global Head of 3D Printing at Henkel. “With decades of development experience, InterPRO has a deep knowledge in adopting additive manufacturing to reduce the time and cost to engineer, test and manufacture new products.”

Elsewhere, digital innovation center IAM 3D HUB has added the latest metal 3D printing model from global engineering technologies firm Renishaw to its facility. Equipped with four 500W high-power lasers, the RenAM 500Q will replace the AM 250 and AM 400 models to enable more precise build rates up to four times faster than possible with the previous systems.

The new equipment will be incorporated into IAM 3D HUB’s recently expanded facilities, which now span almost 800 square meters. The hub has also expanded its fleet of HP Multi Jet Fusion 3D printers.

New 3D printing materials

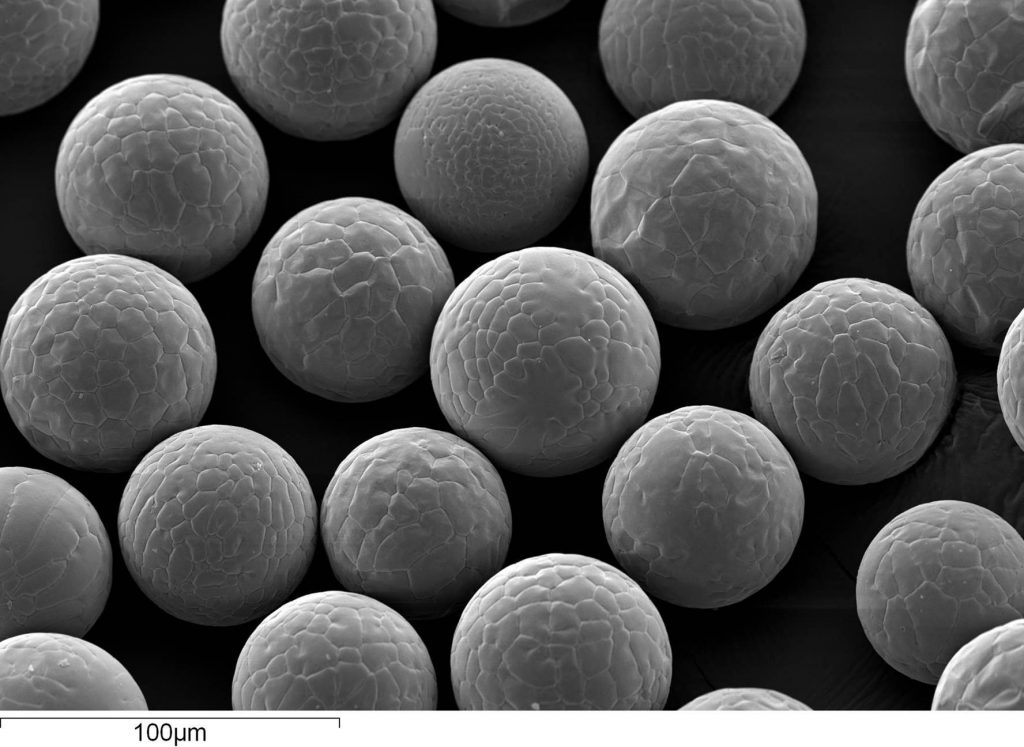

Canadian additive manufacturing powder producer Equispheres has launched three new lines of high-performance aluminum powders developed to provide enhanced strength, print precision, and print speed. The new powders are variations of Equispheres’ original atomized AlSi10Mg aluminum alloy powder and named Equispheres’ Performance, Equispheres Precision, and Equispheres Production.

The Performance powder is designed to increase printed part strength and performance across a variety of applications, while the Precision powder has been crafted to support applications requiring fine features and detail. The production powder has been developed to reduce the cost per manufactured part and facilitate rapid printing without compromising mechanical performance.

“Equispheres’ unique proprietary atomization process is carefully controlled and can be managed with precision,” said Dr. Conlon, CTO at Equispheres. “Powder features such as PSD (particle size distribution), morphology, and chemistry can be optimized to achieve specific behavior in the laser melting process and to meet defined application requirements.”

Another new arrival on the 3D printing materials scene is the latest filament from French industrial composite firm Nanoe, H13 Zetamix filament. H13 is a high-temperature resistant steel known for its favorable ductility, thermal and electrical conductivity, and resistance to corrosion. Combined with Zetamix technology, the filament is designed for the production of on-demand tools or complex steel parts.

The H13 Zetamix filament is compatible with all FFF 3D printers and requires a thermal post-process in a tubular furnace to achieve a density of more than 90 percent.

America Makes launches new project call focusing on materials data

US national accelerator America Makes has announced two new Rapid Innovation Calls (RICs) to optimize additive manufacturing materials data and further qualification and certification efforts within the supply chain. The RICs are worth $100,000 in funding from the Air Force Research Laboratory (AFRL), the Materials and Manufacturing Directorate, and the Manufacturing and Industrial Base Technology Division, and will seek to develop a searchable and scalable materials database capable of compiling data from more than 75 America Makes projects.

“Both of today’s RIC topics address distinct areas focused on leveraging data to facilitate a more expansive and broader understanding of AM materials, processes, and qualification, which will lead to the creation of critical reference standards for AM products,” said Brandon Ribic, America Makes Technology Director.

To be eligible for the RIC participants must be America Makes members, and the submission deadline is 5pm EDT on February 8th. The project awards announcement will be made on February 22nd, and an informational webinar on the RICs will take place on January 27th at 2pm EDT.

Sintavia broadens rocket manufacturing capabilities with M4K-4 printer additions

Metal 3D printing service Sintavia has incorporated two M4K-4 3D printers from EOS Group company AMCM to help expand its rocket thrust chamber design and manufacturing activities for the commercial space sector. A stretched version of EOS’ M400-4 3D printer, the M4K-4 uses four 1kW lasers to print single-unit components with 45x45x100cm dimensions, and can print an entire thrust chamber assembly as a single unit. The printers will be delivered in June and July this year.

“Since the acquisition of our first M400-4 three years ago, Sintavia has devoted tremendous resources to developing successful and repeatable operating procedures for the quad laser printing of extremely thin walls, such as those found in the thrust chamber of a rocket,” said Brian Neff, Sintavia’s CEO. “We now have eight M400-4 quad laser printers, and we expect that the successful strategies employed on the M400-4 will likewise work on these new MK-4 units.

“We are pleased that we will be the first rocket printer in North America to offer the expanded footprint of the M4K-4 to our commercial space customers.”

Ending on something sweet

3D confectionary start-up Sugar Lab has announced a new line of 3D printed chocolate truffles and bonbons in time for Valentine’s Day. The firm worked with Chef Melissa Walnock of the Culinary Institute of America to develop the chocolate ganache recipes which are then enveloped in 3D printed chocolate shells. Sugar Lab’s 3D printed Valentine line also offers sweets, cupcake decor, cocktail garnishes, and pastry shells that can be filled with mousse or ice cream by customers.

“3D printing brings so much flexibility to the table for our customers,” said Sugar Lab Co-founder and CEO Kyle von Hasseln. “We can create complex and beautiful foods that really have to be seen to be believed. Equally significant, 3D printing allows for fast design iteration without the need for molds. This means we can quickly brand and personalize existing designs with something unique for each customer.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sugar Lab’s new line of 3D printed chocolate truffles and bonbons with the SLICED logo.