In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a suite of new scanning software, several distribution deals, some novel automotive parts, a new additive competition with a €185,000 prize and a rather fetching 3D printed casing for a perfume bottle.

Read on for the most recent updates from Forward AM, Solukon, M.Holland, Evatronix, ProtoTech, EIT Manufacturing, Infinite, Hawk Ridge and more.

PostProcess, AMT and Solukon sign distribution deals

Beginning this week with distribution agreements, post-processing specialist AMT has announced that service bureau Additive3D Asia will become the first in the region to offer its PostPro3D system. According to the firm’s Co-Founder Jason Joo, the machine will now allow its clients to fabricate end-use parts that address a wider range of industries.

“The current market perception of 3D printed parts or products is that they are mainly for prototyping or R&D purposes,” said Joo. “Current challenges with 3D printed items, including surface finishing and part strength, are now answered with the automated Chemical Vapor Smoothing process from PostPro3D.”

Elsewhere, post-processing system manufacturer PostProcess has signed distribution deals with 3D printing service providers Excelencia-Tech and 3D Bonum. While Excelencia will market the PostProcess’ products to Spanish prototyping and production clients, 3D Bonum is set to sell the machines in Lithuania, Latvia and Estonia.

“Both 3D Bonum and Excelencia-Tech hold visions that align with our dedication to innovation for the additive industry,” said Bruno Bourguet, Managing Director of PostProcess. “We look forward to leveraging these new comprehensive networks to bring cutting-edge technology and transformative end-to-end digital connectivity to more additive workflows.”

Post-processing system manufacturer Solukon has also formed a distribution partnership, but with HASMAK-T, one of the biggest resellers in Turkey. HASMAK-T also serves as a tech consultant for its clients, and in its new role as distributor, it will now try to help its customers explore the benefits of adopting Solukon’s Smart Powder Recuperation technology.

“The demand for repeatable and reliable cleaning results has grown a lot in the last year all over the world,” said Michael Sattler, Global Sales Director at Solukon. “By establishing HASMAK-T as our trusted partner for the Turkish market, we take the next step to ensure our position as Best-in-the-Industry of depowdering solutions.”

Material news from Infinite, Henkel and M.Holland

On the filament front, material supplier Infinite Material Solutions has entered into a distribution partnership with research firm Controllo Qualità. The deal has seen Controllo qualify a number of Infinite’s AquaSys thermoplastics in its labs, and it will now become the first authorized reseller of the materials in the Italian market.

“Controllo Qualità is the true definition of an early adopter and trusted partner” said Larry Doerr, COO of Infinite. “They are focused on determining the boundaries of performance, collaborating to understand best practice printing parameters, helping get the word out, and achieving success with the AquaSys materials.”

3D printing equipment manufacturer Asiga has announced a development in its long-running partnership with global chemical firm Henkel. Essentially, Asiga has now validated Henkel’s Loctite industrial resins, including its new flame-retardent 3955 FST material, for use with its dental-oriented Pro4K system.

Asiga´s German reseller Litholabs has also worked with Swiss electronics firm ERNI to 3D print functional connectors out of the new polymer. By utilizing the Asiga system and 3955 FST together, ERNI has managed to reduce the lead times of its PCBs, and develop prototypes more quickly than with conventional metal tooling.

“As a reseller of Asiga 3D printers, we acquire a lot of experiences working with customers from various industrial backgrounds,” said Axel Schwan, Founder of Litholabs. “The innovative Loctite 3955 resin from Henkel arrived just in time to meet the demand for highly functional and technical 3D printing solutions.”

Finally, in terms of material news, U.S-based resin distributor M.Holland has launched a brand new e-commerce website for 3D printing materials. The web-optimized platform is designed to streamline the ordering process, by providing clients with easy access to the firm’s resins, as well as its suite of consultation, engineering and training services.

“Our primary focus is furthering the adoption of 3D printing by providing effective education, offering quality products and showing clients how to maximize their return on investment,” said Haleyanne Freedman, M. Holland’s 3D Printing Market Manager. “If we can help people find and understand which materials are best for their applications, we are supporting the industry as a whole.”

Thor3D, Evatronix and Hawk Ridge provide software updates

3D scanner manufacturer Thor3D has and advanced tech firm ProtoTech Solutions have partnered to offer their Calibry device and 3D Measure Up software as a bundle. Once combined, the products allow users to rapidly and precisely obtain body scan data, something that could be of interest to clients in the apparel, medical or sports industries.

“We are glad to partner with Calibry who are leaders in handheld scanners,” said Rajesh Bhartiya, Founder and CEO of ProtoTech. “Our technologies complement each other very well and can help companies, small businesses, and individuals have quick access to ‘contactless measurements’ at a very reasonable price.”

3D design and manufacturing solutions provider Hawk Ridge Systems has formed a ‘strategic partnership’ with the developers of the SolidProfessor engineering design software. The deal allows Hawk Ridge to offer its clients exclusive access to online training, including courses that range from the basics to the much more advanced.

According to Dale Ford, President and CEO of Hawk Ridge, the COVID-19 pandemic has caused a shift in demand from in-person learning to on-demand training options. “Our customers have been asking us for more online training options, as employee training has evolved from a nice-to-have, to essential,” said Ford.

“SolidProfessor is the absolute best online training platform there is – and dominant in the engineering design software training space,” he added. “The fact that we have a long history together with shared customers made for a very compelling strategic partnership on so many levels.”

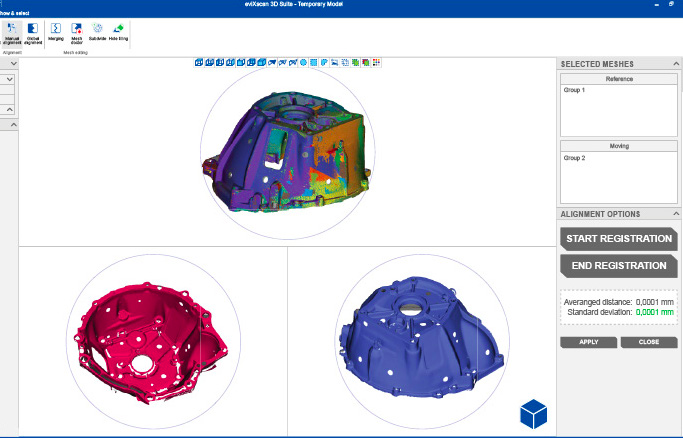

Elsewhere, another 3D scanner producer, Evatronix, has launched an update for its front-end eviXscan software. Version 2.7 introduces an ‘autoexposure’ feature, that automatically estimates the optimal level of scanner brightness for users, as well as a new tool for defining the variable steps of a system’s rotary table.

The update also upgrades the program’s graphics engine, improves its point cloud generator and allows users to use a mesh triangle overlay as a means of better analysing surface topology. Clients that choose to purchase the new software will gain access to each update introduced over the next 12 months as well.

“The newly-issued software package offers new functionalities which help and facilitate the 3D scanning process,” said Szymon Ścibik, Software Lead Developer at Evatronix. “We listen to our customers’ and partners’ opinions, which give us directions for further software development, and we adjust eviXscan 3D Suite to their needs.”

New 3D printing applications from Farsoon and L’Oréal

Chinese 3D printer manufacturer Farsoon has released a case study showing that its FS271M system can be used to fabricate car seat safety buckles. One of its clients, the Ruixiang Mould Co, deployed the machine as an alternative to CNC machining, and found that it not only improved throughput, but the part quality as well.

“The adoption of Farsoon additive technology has proved to be successful for series production,” said Mr. Zhang, GM of Ruixiang Mould. “Our safety seat buckle was able to cut the production cycle by 28%, and achieve a great improvement to production volume and part quality, which has brought a positive impact to our clients.”

In another very different application, L’Oréal perfume brand Viktor&Rolf has revealed that using 3D printing, it has shortened the time to market for its new products. As of last year, 100% of the firm’s design centers included 3D printers for prototyping, and it’s now leveraging the technology to create luxury casings for its Flowerbomb fragrances.

“As part of our digital transformation, we have been using additive manufacturing to prototype our packaging in-house,” explained Cristina Monnoyeur, Global Digital Transformation for Operations at L’Oréal. “This decision has reduced the time from design to prototype from several days to about 12 hours.”

Industry partnership updates from EIT, AM-Austria and more

The European Institute of Innovation and Technology (EIT) Manufacturing has partnered with the 3D printing non-profit AM-Austria to advance the technology’s adoption across Europe. Together, the organizations intend to pool their resources and establish joint initiatives, that help to meet global challenges and strengthen the additive industry as a whole.

“EIT Manufacturing aims to create dynamic partnerships to realise our vision and mission along the knowledge triangle – innovation, business creation, and education,” said Hannes Hunschofsky, Managing Director of EIT. “The cooperation with AM-Austria strengthens and enriches our extensive network and helps us serve the Austrian ecosystem.”

Similarly, Insurance and specialty technology provider HSB is working with the Connecticut Center for Advanced Technology (CCAT) to identify new industrial 3D printing applications. As part of a multi-year deal, HSB will now be granted access to CCAT’s R&D center in Connecticut, where it will attempt to find novel methods of de-risking additive adoption.

“Additive manufacturing is driving innovation in the way our customers make and use parts and products,” said John Riggs, Senior VP of HSB Applied Technology Solutions. “We are excited to be working with a leading technology organization such as CCAT, to help advance the adoption of technology in the marketplace as we develop ways to reduce risk throughout the value chain of manufacturing.”

Forward AM launches new additive award

Concluding this week’s round-up with competition news, BASF subsidiary Forward AM has launched a new contest that’s designed to reward start-ups involved in novel 3D printing applications. Called the ‘Forward AM Innovation Award,’ the competition, which is now open, is searching for entries that are innovative, scalable and focused on sustainability.

Once the contest concludes on March 28th 2021, the selected winner is set to receive €185,000 worth of products and services from the award’s sponsors. The victor will also get the opportunity to meet venture capitalists from AM Ventures, as well as those from BASF Venture Capital, as part of a dedicated session.

Additionally, alongside the main prize, applicants will be entered for the ‘Deloitte Sustainability Award,’ and the start-up with the best sustainability strategy will be awarded €10,000. One participant is also set to be rewarded with the ‘People’s Choice Award’ at the finals in June, as well as €15,000 in goods and services.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our Facebook page.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of a Viktor&Rolf Flowerbomb bottle. Photo via L’Oréal.