The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now. Make sure to tune in to the live stream of the event on our YouTube channel.

In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features business updates, new 3D printing partnerships, material launches and qualifications, rocket testing milestones, innovation projects, and fresh funding to tackle climate change.

Read on for the most recent updates from Covestro, Radtech, Farsoon, Divergent Technologies, iMakr, Alliance University, Wipro 3D, PrinterPrezz, Branch Technology, At One Ventures, Wohlers Associates, Accumold, Fiberlogy, and more.

Business updates from Ultimaker, iMakr, PrinterPrezz, Accumold, and SLM Solutions

Dutch 3D printer manufacturer Ultimaker kicks off this week’s business news with the announcement of a new promotion to celebrate its 10-year anniversary. The offer, which is running throughout Q4 2021, enables new users to unlock its entire ecosystem with a 20 percent discount, incorporating a 3D printer, professional software, materials and a one-year warranty extension. Those taking advantage of the offer will also have access to the Ultimaker Academy.

Ultimaker CEO Jürgen Von Hollen said: “Our 10-year anniversary campaign is all about celebrating these customer WOW-moments and to offer an Anniversary Value Pack to give more companies the opportunity to see for themselves how Ultimaker has cracked the code on how to take the complexity out of 3D printing at a mainstream business level.”

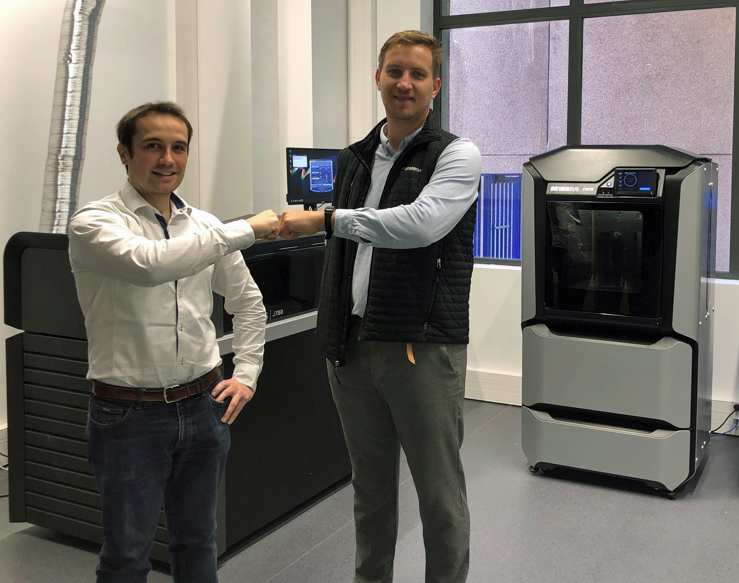

Elsewhere, global 3D printer, scanner, and services reseller iMakr has expanded into the Nordic region with the launch of iMakr Nordic in Copenhagen, Denmark. The new showroom will be headed up by CEO Jan Fischer and has been established to offer Nordic customers the opportunity to learn about and experience the firm’s technology first-hand.

Medical 3D printing bureau PrinterPrezz, meanwhile, has acquired advanced manufacturing service provider Vertex Manufacturing in order to merge the two companies’ technologies and target markets. Founded in 2020 by Morris Technologies founder Greg Morris, Vertex Manufacturing leverages 3D printing machines from the likes of VELO3D and GE’s Concept Laser.

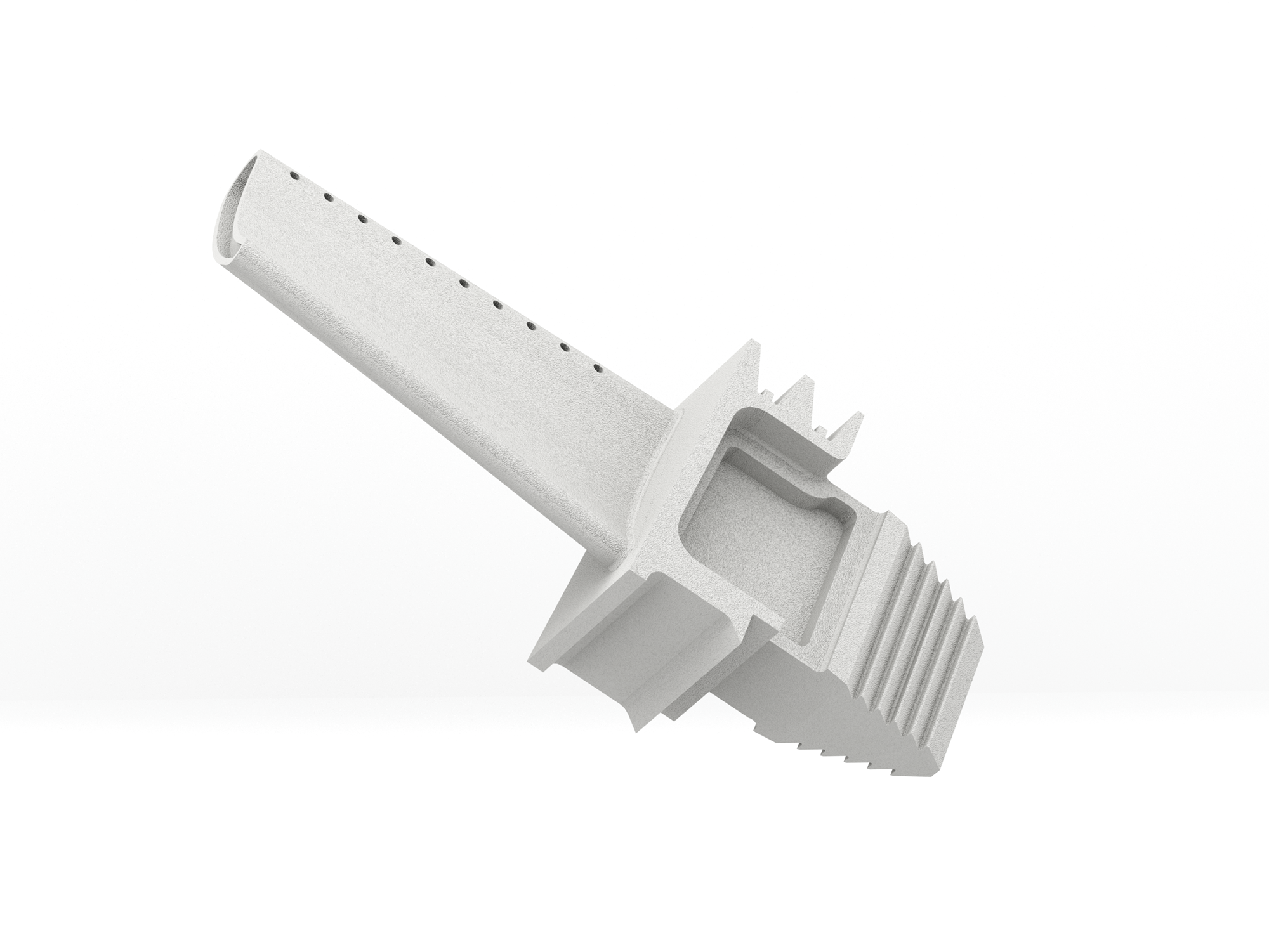

PrinterPrezz and Vertex Manufacturing first started working together in April to provide customers with multiple combined services to support the 3D printing of medical devices. Now, the companies are merging, with PrinterPrezz’s Silicon Valley facility continuing to focus on medical devices, and Vertex Manufacturing serving the medical, aerospace, defense, oil and gas, energy, and consumer sectors from its Cincinnati base in Ohio.

In other business news, micro injection molding firm Accumold has invested in a Fabrica 2.0 micro additive manufacturing machine from Fabrica Group, previously known as the Tera 250 created by Nanofabrica, before the company was acquired by Nano Dimension earlier this year.

Accumold will leverage the machine to enhance the design, functionality, and versatility of its product development services for micro parts with complex geometries. The firm also hopes to achieve significantly shorter lead times and reduced costs with the Fabrica 2.0, and sees the field of direct rapid soft tooling (DRST) presenting “huge future opportunities” thanks to the machine’s accuracy and material robustness.

“The hugely impressive technology that Fabrica Group has developed will in short order add significant possibilities for us and our customers,” said Roger Hargens, CEO and President of Accumold. “With the Fabrica 2.0 we can already cater for customers requiring low to medium size runs economically, as the same economies of scale do not exist when using AM as opposed to traditional molding technologies. We can also create micro parts with geometric complexity either impossible or prohibitively expensive using the micro molding process.”

Rounding off this week’s business updates is a move from automotive manufacturing firm Divergent Technologies that will see its Divergent Adaptive Production System (DAPS) strengthened by the addition of three NXG X11 600 3D printing systems from 3D printer manufacturer SLM Solutions. The latest installation will bring Divergent’s total number of NXG X11 600 systems to six, making the firm the largest holder of this model in the US, and will supplement its current install base of seven SLM 500 systems, three SLM 280 systems, and one SLM 125 system.

“The purchase of the SLM NXG X11 600 is the culmination of years of intensive joint development that completes the shift from prototyping to production of complex structures, when combined with the DAPS as the future of human-AI design and sustainable systems,” said Kevin Czinger, Founder and CEO of Divergent, and SLM Solutions Supervisory Board Member.

New 3D printing partnerships from Stratasys, Covestro, RadTech, Farsoon, Branch Technology and Alliance University

Moving onto partnership news now, and 3D printer manufacturer Stratasys has signed an agreement with French med-tech start-up Bone 3D to deploy its technology throughout France’s hospital network. Through Bone 3D’s Hospifactory initiative, healthcare institutions will have direct access to Stratasys’ latest FDM and PolyJet 3D printing systems to produce medical equipment, devices, and patient-specific anatomical models.

To date, Bone 3D has invested in more than 30 Stratasys 3D printers, including the J750 Digital Anatomy system, the J5 MediJet system, and F-Series FDM printer, which hospitals can sub-contract to fulfill their production needs on-site.

“The versatility of 3D printing has seen a huge demand from hospitals and medical institutions for a means to create maintenance parts, rehabilitation parts, and medical devices,” said Jérémy Adam, CEO and Founder of Bone 3D. “Our Hospifactory initiative will ensure that some of the market’s most advanced 3D printing technologies are made accessible exactly where and when they are needed by surgeons and clinicians across the French hospital network.”

Polymer 3D printing specialist Covestro, meanwhile, has expanded its distribution partnership with thermoplastic resin distributor Nexeo Plastics. As a premier distributor, Nexeo Plastics will offer direct global distribution of additional Covestro filaments and Somos resins for SLA and DLP/LCD 3D printing.

The companies have been working together since 2016 to distribute 3D printing filaments throughout Europe and North America, and will now broaden this partnership in line with material expansions and increased inventory storage locations.

Carrying on with distribution partnerships, and 3D materials distributor 3D Solutions has become a “France-exclusive” sales agent of Farsoon Europe, the German subsidiary of PBF systems manufacturer Farsoon Technologies. 3D Solutions will make its entry into the 3D printing market by supplying Farsoon’s Open Laser Sintering systems to its customers in France.

“3D solutions is very well experienced in selling machines and tools into classical manufacturing industry in France,” said Dirk Simon, Managing Director of Farsoon Europe. “The production industry in these countries will strongly benefit from combining competencies of classical with additive manufacturing.”

RadTech, the non-profit association for UV+EB photopolymer chemistry, has partnered with the National Institute of Standards and Technology (NIST) to form the Photopolymer Additive Manufacturing Alliance (PAMA). PAMA’s mission is to engage industry, academia, government, and NGOs to advance materials and systems science for 3D printing.

The new group will be introduced via a three-part virtual workshop taking place 16-18th November between 1-3 pm EDT each day. Building on the Photopolymer Additive Manufacturing Roadmap developed by RadTech and NIST in 2019, the workshop will provide an overview of the opportunities for photopolymer materials and systems characterization within 3D printing, and accelerate research and partnerships in the field.

The last of this week’s partnership updates involves Alliance University Bangalore and Bangalore-based metal 3D printing service provider Wipro 3D, who have signed a Memorandum of Understanding (MOU) to provide students with hands-on training for digital manufacturing.

The partnership will see the partners offer a 40-day course module covering the design and development of industry-aligned Internet of Things (IoT) centers, IDEA labs, online skilling, and proficiency development programs in digital manufacturing and IoT. The partners will also offer competency building and advisory programs related to additive manufacturing, and students will be given the opportunity to work on live projects upon completion of the course.

New materials from Forward AM, Fiberlogy, qualification from Desktop Metal

Onto materials news now, and Forward AM, the additive manufacturing arm of BASF, has launched its new Ultrafuse Flexible Filament portfolio. Consisting of three filaments – Ultrafuse TPU 64D, Ultrafuse TPU 95A, and Ultrafuse TPS 90A – the flexible material portfolio is engineered to enable the easy, rapid, and cost-efficient production of FFF 3D printed parts.

The new filaments were developed with demanding industrial applications in mind. The Ultrafuse TPU 64D is the hardest elastomer in the range, maintaining excellent flexibility while offering high rigidity for impact-resistant parts, while the Ultrafuse TPU 95A is well-suited for wear and tear applications due to its high abrasion resistance, durability, and flexibility.

The third new material in the portfolio, Ultrafuse TPS 90A, stands out due to its “unprecedented” soft-touch surface haptics. The material’s low moisture uptake and high layer adhesion make it suitable for the 3D printing of two-component parts and appliance grips.

Polish filament provider Fiberlogy has also launched a new flexible rubber-like filament, MattFlex 40D, which provides a matte finish to 3D printed parts. According to Fiberlogy, excellent results can be achieved when printing the material at 45 mm/s, more than double the typical recommended printing speed of flexible filaments.

MattFlex 40D’s mechanical properties make it suitable for a range of practical applications from model and robot tires, gaskets, and vibration damping pads, to clothing components and wristbands for smartwatches.

Meanwhile, industrial 3D printer manufacturer Desktop Metal has qualified nickel-chromium superalloy IN625 for its Production System platform. Characterized by its high strength, resistance to corrosion, excellent weldability, and ability to withstand extreme temperatures for parts under load, IN625 is used extensively in high-temperature aerospace, marine, power generation, and chemical processing applications.

“As Desktop Metal continues to drive our internal R&D efforts to qualify more materials for the Production System platform, we are excited to offer customers an all-inclusive binder jetting solution to print fully characterized IN625 with excellent properties,” said Jonah Myerberg, Co-founder and CTO of Desktop Metal. “We anticipate continuing the rapid expansion of our materials portfolio in the coming months as we look to accelerate the deployment of our AM 2.0 solutions to produce end-use metal parts at scale across a growing array of industries and applications.”

3D printing projects and awards from European Laser Institute and Branch Technology

The European Laser Institute (ELI) and Arbeitskreis Lasertechnik have put out an open call for applications for the 2022 Innovation Award Laser Technology, a European research, and technology prize for successful and innovative projects related to laser technology. A total prize money of €10,000 is on offer for the winner, who can be an individual researcher or an entire project group.

Examples of potential successful projects include developing new laser beam sources and systems for use in laser materials processing, and the qualification of innovative laser manufacturing processes for industrial production environments. The closing date for proposals is 17th January, 2022, and the official presentation of the award will take place in Aachen at the International Laser Technology Congress on 4th May, 2022.

Those interested in applying for the 2022 Innovation Award Laser technology can do so here.

Elsewhere, construction 3D printing firm Branch Technology recently won the NASA 3D printed Habitat Challenge. Partnering for the project with Stanford University and Foster + Partners, the company won a cooperative agreement from NASA to investigate in-situ derived materials for freeform 3D printing and cellular fabrication (C-Fab) on the moon.

The project is set to take several years, with the ultimate goal to prove the possibility of 3D printing habitats on the moon using Branch Technology’s C-Fab technology and robotics. In other news from the company, Branch Technology has also used its C-Fab 3D printing technology to build and install a 16-foot sculpture at the Chattanooga Metropolitan Airport. Made of six separate parts, the sculpture totals 300 square feet and is 3D printed in a carbon-fiber reinforced polymer.

Wohlers Associates publishes post-processing report

Colorado-based additive manufacturing consultancy firm Wohlers Associates has released a special report that delves into the various time-consuming and often expensive steps in the post-processing of 3D printed parts. The report, titled Post-Processing of AM and 3D-Printed Parts, saw input from 124 service providers in 27 countries.

According to the publication, nearly 27 percent of the cost of producing AM parts comes from post-processing. As well as detailing the current drawbacks of post-processing methods, the report describes various methods and techniques to reduce the trial-and-error approach that many organizations currently use. Further information on the report can be found here.

At One Ventures raises $150 million to “destroy the industries that destroy nature”

Planet-positive venture capital firm At One Ventures has closed $150 million in capital for its first fund, which it will use to grow early-stage companies looking to improve the future of the planet. Launched by Google X co-founder Tom Chi, At One Ventures plans to invest over $1 billion in innovators looking to upend traditional industries that are the largest contributors to climate change.

One technology At One Ventures is keen on investing in is 3D printing construction, having already invested in Boston-based construction firm Apis Cor which recently completed a $750,000 robotic 3D printed “Impreza” house.

“At One Ventures’ work stems from a passion for rebuilding our current economic infrastructure to empower humanity to repair our ecosystems and climate,” said Chi. “We should also presume that the vast majority of current industries (built on unsustainable premises) will need to shut down far faster than we have projected. A willingness to face the magnitude of the planetary citation must prevail.

“By enabling old industries to persist without radical changes, we may protect 1,000 jobs, but at the cost of 10,000 lives. Our mission is to care about life on this planet first, and reform the outdated industries with this new foundational understanding.”

In other news, American professional golfer Rickie Fowler was spotted with a unique 3D printed putter in his bag at the recent Shriners Children’s Open competition. The putter was a Cobra prototype that featured a 3D printed Sport-45 head in 316 Stainless Steel, and was reportedly designed to offer more consistent roll and put distance.

Relativity Space makes history with 3D printed rocket testing

3D printed rocket manufacturer Relativity Space has hit new milestones in the testing of its fully 3D printed Terran 1 rocket, slated for launch early next year. Having placed Stage 1 of the rocket onto its test stand, the team successfully completed hydro proof testing, cryogenic proof testing, and flight pressure testing of the Terran 1, which it claims is the largest and tallest 3D print to undergo such tests.

Relativity Space has also released a timelapse of the building of the nose cone for its Terran 1 rocket, and is the first time the company has created the shape using 3D printing and zero fixed tooling.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a render of Relativity Space’s Terran 1 rocket with the Sliced logo.