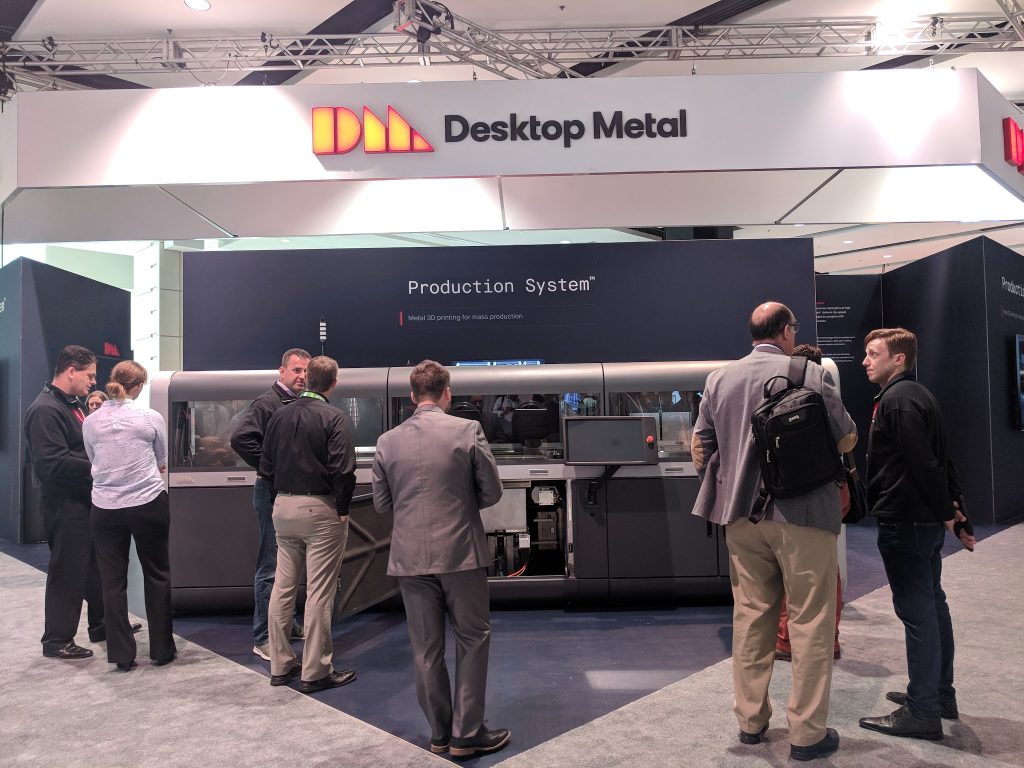

On the first day of Formnext 2018, Boston metal 3D printer provider Desktop Metal has launched an upgrade of its industrial scale Production System.

Scheduled for installation with its first customer at the start of 2019, the Production System has undergone a number of major advancements promising to deliver “the lowest cost per part with the highest capacity of any metal 3D printing system available.”

According to Ric Fulop, CEO and co-founder of Desktop Metal:

“We are excited to provide the international engineering and design community with deeper insights into the power of the Production System with updated innovations and an extensive display of metal parts to be publicly shown for the first time this week.”

In addition to new parts from the system, the company also boasts that these updates make the Production System “the fastest metal printer in the world.”

Single Pass Jetting technology

The Production System, in contrast to the company’s compact FFF-based Studio System, is a large scale machine that works using Single Pass Jetting (SPJ) technology – an inkjet and powder based method of metal 3D printing.

In this most recent upgrade, the build envelope of the Production System has reportedly been increased by 225% to a measurement of 750mm x 330mm x 250mm, as seen at IMTS 2018. Further, increasing the initial print speed by 50%, the Production System now has averages a rate of 12,000 cm3/hour, equating to more than 60 kg of metal per hour.

For complex parts, consolidation and mass serialization

As a demonstration of the Production System’s capabilities, Desktop Metal has prepared three cornerstone case studies, each addressing key challenges in industrial 3D printing.

For complex part production, Desktop Metal shows the Milwaukee® Tool spauger bit. An intricate precision tool head, the spauger bit has been created on the Production System in a 4 step process, compared to a total of 14 steps needed in the traditional manufacturing process.

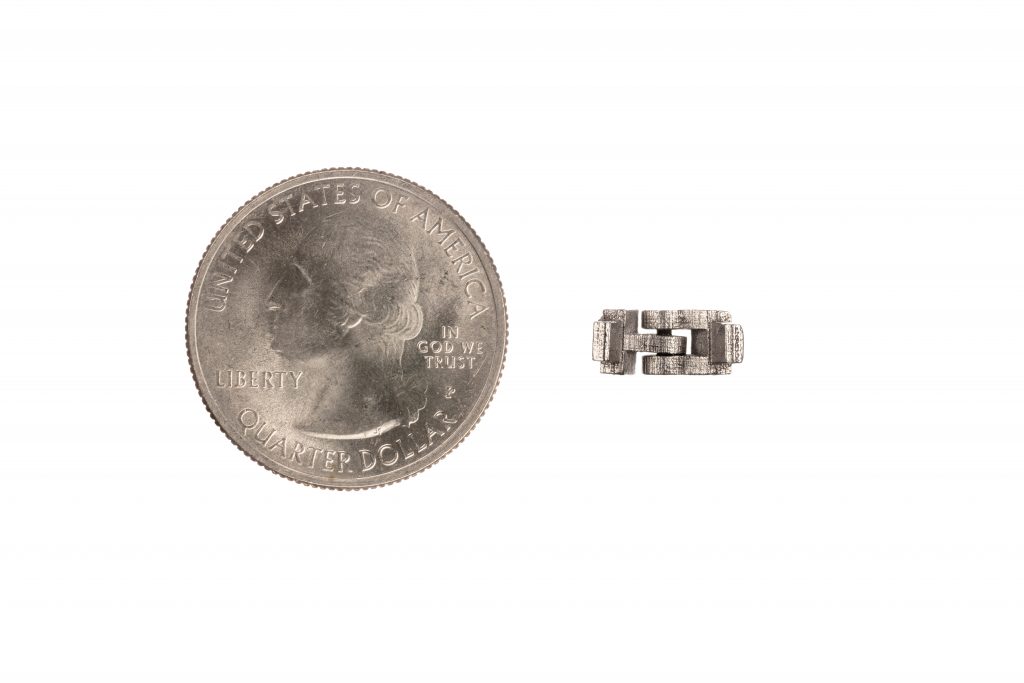

Further, part consolidation is demonstrated at high volume by a batch of print-in-place hinges, akin to the kind you use to build a metal watch strap. Measuring just 12 x 5 x 6 mm each, the Production System can print over 20,000 of these hinges in a single four-hour build.

And, for mass serialization the company demonstrated a set of gears each 3D printed with and individual ID number. Custom markings of this nature can be automatically generated when 3D printing on the Production System, cutting out the need to process each part independently.

Production System availability

The first customer of the Production System has been confirmed by Desktop Metal as “a Fortune 500 company” among the company’s early Pioneers. Throughout 2019, the company expects further customers installations of the Production System “at major automotive, heavy duty and leading metal parts manufacturers,” with widespread availability scheduled for 2020.

In closing comments, Fulop says, “As we continue to expand our list of global customers and partners, companies that are turning to the game-changing technology available with the Production System, and installations set to begin rolling out in the coming months, Desktop Metal is looking to further shift the industry beyond prototyping to now include full scale metal manufacturing.”

The first sample use cases 3D printed by the upgraded Production System are on display at Formnext 2018 – hall 3.0, booth C10.

For to-the-minute updates live from Formnext follow 3D Printing Industry on Twitter, like us on Facebook and subscribe to our daily newsletter. Seeking your next opportunity in this fast faced industry? Sign up to 3D Printing Jobs. Employers – advertise now to reach our specialist talent pool.

Featured image shows a Production System 3D printed hinge with quarter for scale. Photo via Desktop Metal