The 3D printing industry is expanding with new facilities unveiled by FIT AG, Dassault Systèmes, Airbus and GE Aviation.

FIT AG, a German additive manufacturing company, has lifted the curtain on its new €20 Million German headquarters which was announced back in 2015. While French company, Dassault Systèmes has launched a new site in the US at Wichita State University (WSU) along with Airbus. Also in the United States, GE Aviation has held the grand opening ceremony for a ‘Brilliant Factory’ in Muskegon, Michigan.

The 3DEXPERIENCE Center

Dassault Systèmes’ newest 3DEXPERIENCE Center at Wichita State University is part of an ongoing collaboration with the academic institution. The French software company announced plans during Solidworks this year, to develop another separate 3DExperience center at their Boston Headquarters.

Automated ribbon cutting, @Dassault3DS at @WichitaState pic.twitter.com/KjlF6ee2yG

— Daniel McCoy (@ICTBiz_dmccoy) April 27, 2017

Michel Tellier, VP aerospace and defense industry at Dassault Systèmes believes this partnership with WSU, “is a model for how public institutions and businesses can work together for the advancement of new technologies.” Tellier went on to say,

Our new 3DEXPERIENCE Center is going to help businesses solve today’s problems while training the workforce of tomorrow. The advanced manufacturing techniques, new materials research and 3D simulation innovations that are unveiled in this new facility will have an immediate impact on the aerospace industry, and will also be applicable to countless other industries across the world.

Airbus’ Engineering Center

Accompanying Dassault Systèmes, aviation company Airbus has also expanded to Wichita State University’s Innovation campus. Airbus will occupy a two-story 90,000 square foot building to house 300 employees. John O’Leary, vice president of Airbus Americas Engineering, explained the location was strategic as “Wichita’s talent pool of aerospace and aviation experts is among the richest in the world.” Along with Dassault Systèmes, Airbus – as partners of WSU – will have access to research labs, meeting facilities, training and education facilities as well as the opportunity for collaboration with faculty, staff and students.

At the new facility, Airbus will commence design work on aircraft including the A350 XWB which has a significant 3D printing presence.

GE Aviation’s ‘Brilliant Factory’

GE’s newest facility, the ‘Brilliant Factory’, has been unveiled in Muskegon, Michigan. According to John Bowman, general manager Supply Chain at GE Aviation, the 35,000ft2 building “is the first of several GE Brilliant Factories being built throughout the world where machine downtime has been reduced to less than 1%.”

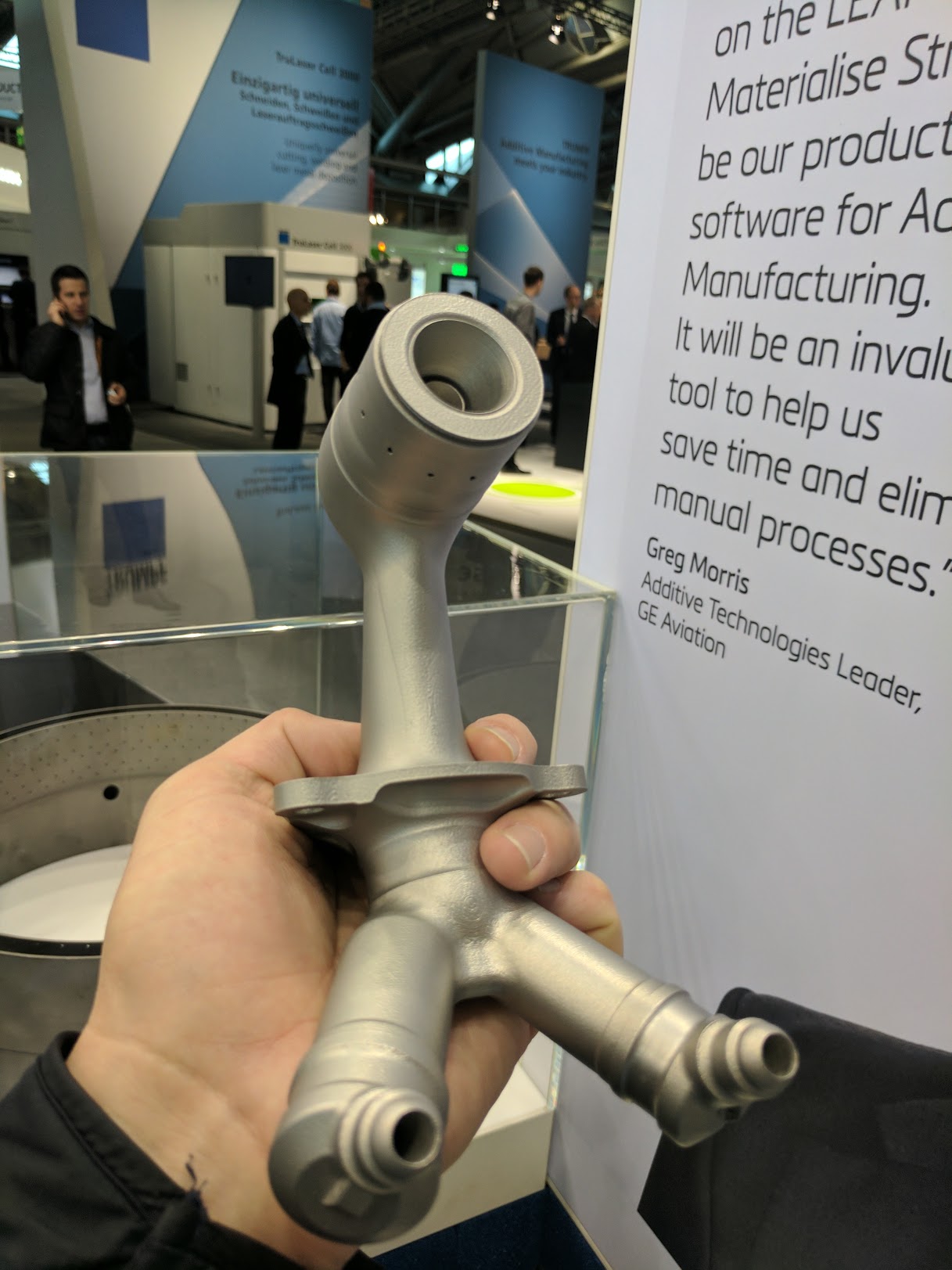

The $14.5 million factory will produce parts for the GE90 engine which will be utilized by Boeing’s 777 aircraft. GE Aviation has turned to additive manufacturing for the development of its aircraft engines and more recently acquired two major metal 3D printing companies. GE is testing 3D printed components in its GE9X engine and has received FDA approval for the 3D printed LEAP engine nozzle.

Speaking at the unveiling of the Muskegon facility, Bowman also said,

GE’s brilliant factories combine the newest technologies, from advanced analytics to 3D printing to collaborative robots that work side-by-side with people. The facility represents an investment in advanced manufacturing – our workforce is constantly adapting and updating their skills for the jobs of tomorrow.

FIT AG’s German headquarters

According to FIT AG, the opening of its new site now gives the company the “highest capacity for the additive manufacturing of metal parts in the world.” The site was unveiled as part of the company’s Technology Day.

Carl Fruth, founder and CEO of FIT AG spoke at the event,

We firmly believe that AM should be a mainstream tool in industrial manufacturing. Our goal is to create a digitized scalable factory and to develop standards for higher volume series metal AM. To get there, processes still have to be more stable, automated and cost-effective. That’s where we are putting all our energy and ambition every day.

Technology Day

At the opening event, FIT AG showcased its additive manufacturing capabilities which includes working with plastics. While the ground floor of the new facility will be concerned with metal additive manufacturing, the floor above will be used for plastic prototyping and injection molding. Producing prototype parts for the automotive industry is a key area of application for FIT AG and the company also announced a collaboration with construction company Caterpillar recently.

Make sure to cast your votes in this month’s 3D Printing Industry Awards.

For the latest 3D printing news, sign up to our newsletter and follow us on twitter.

Featured image shows the atrium of FIT AG’s new facility. Photo via FIT AG.