FIT AG, the German parent company of popular 3D printing software developer netfabb, is experiencing some great growth from the recent boom in 3D printing worldwide. Today, after the latest update to their netfabb software, which has been optimized for mass manufacturing, the company announced the construction of a new €20 facility devoted to high volume 3D printing.

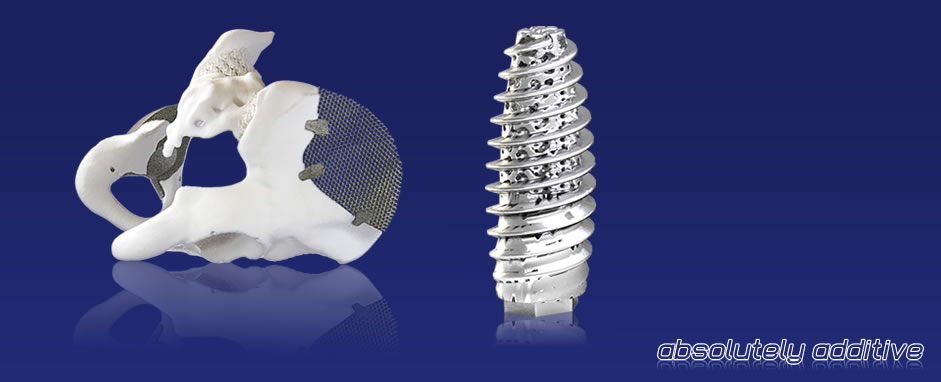

FIT Group has been in business for twenty years providing 3D printing services with systems from EOS, SLM, Arcam, Objet, Voxeljet and Sintermask for production and prototyping in a variety of industries, from aerospace to the medical field. An increase in demand has seen FIT double its production capacity in the past year. This growth has caused the company to pursue a new facility, with doors set to open in 2016, and the launch of a high-volume 3D printing service they are calling FAB@FIT.

CEO of FIT Group, Carl Fruth, says of the company’s growth, “Having bought nine laser melting systems during the last year, we are now going to order three additional big multilaser melting machines as well as two further electron beam melting machines. The more important milestone is, however, to combine these technologies in an integrated purpose built additive factory with reliable processes, minimizing the technology risks. This is what qualifies us as the industrial partner to implement new manufacturing concepts with customers worldwide.”

They also see this growth as a part of a larger industrial adoption of 3D printing. Alexander Oster, CTO of the FIT Group, adds, “We are about to enter a new era of industrial production, and with our new factory we intend to make a major contribution to this trend. The successful development of the new standard format 3MF for industrial print data by Microsoft and FIT has proved to be a good start.”

The FIT Group’s addition to the 3MF Consortium and this new facility indicate the company’s shift from being an important part of the 3D printing industry to global manufacturing as a whole. Combined with the mass 3D printing facility opened by GE, this is also an indicator that there may be more such endeavors to follow from other companies as well.