I’ll never forget the time when, at the invincible age of 13, I was playing tag with some neighborhood friends and, suddenly – BAM – I tripped and broke my hand in three places. I remember the adrenaline and shock took care of most of the immediate pain, but what was really a struggle was wearing the unbearable plaster cast for eight months, the itching, the immobility, the horror. One group of graduates from the National Autonomous University of Mexico (UNAM), who joined together to start Mediprint, are focusing on alleviating this issue by 3D printing personalized casts with less complications then the conventional plaster style that has been used for decades.

“The project started when my mom had an accident at work and broke his left hand. They put her plaster cast wrong, and they had to fracture her hand again surgically to place it right. However, they again placed the splint wrong; and then they diagnosed her with 50 percent disability in that hand,” said Zaid Badwan, a UNAM graduate and founding partner of Mediprint.

Their patented product, which the team calls NovaCast, utilizes 3D printing technology to create a cast that is 10 times lighter than plaster casts, and are also easily removable, more visually appealing, and personalized to the patient. Even more importantly, the 3D printed Nova Cast greatly reduces the chance of accumulating bacteria and ulcers under the casted area, while also reducing the chance that the cast is misplaced, causing the bone to not heal correctly. All-in-all, the NovaCast takes about three-and-a-half hours to print and tailor to a patient. But still, even with these adequate times and ability to produce high quality medical devices, Mediprint remains focused on improving their process even more.

“We are doing research and development to reduce that time to one hour,” Badwan said. “The next steps are bringing this technology to hospitals and increase the number of 3D printers.”

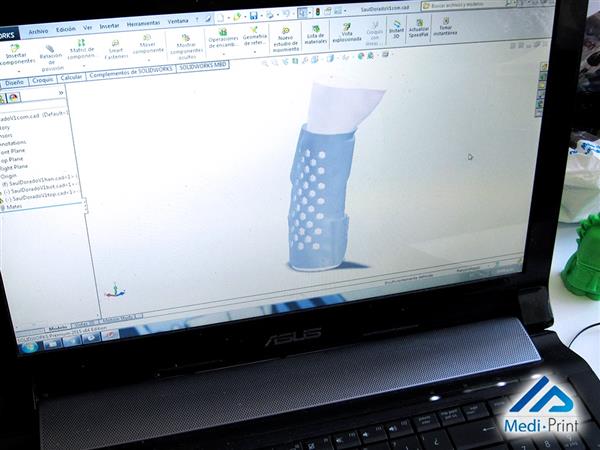

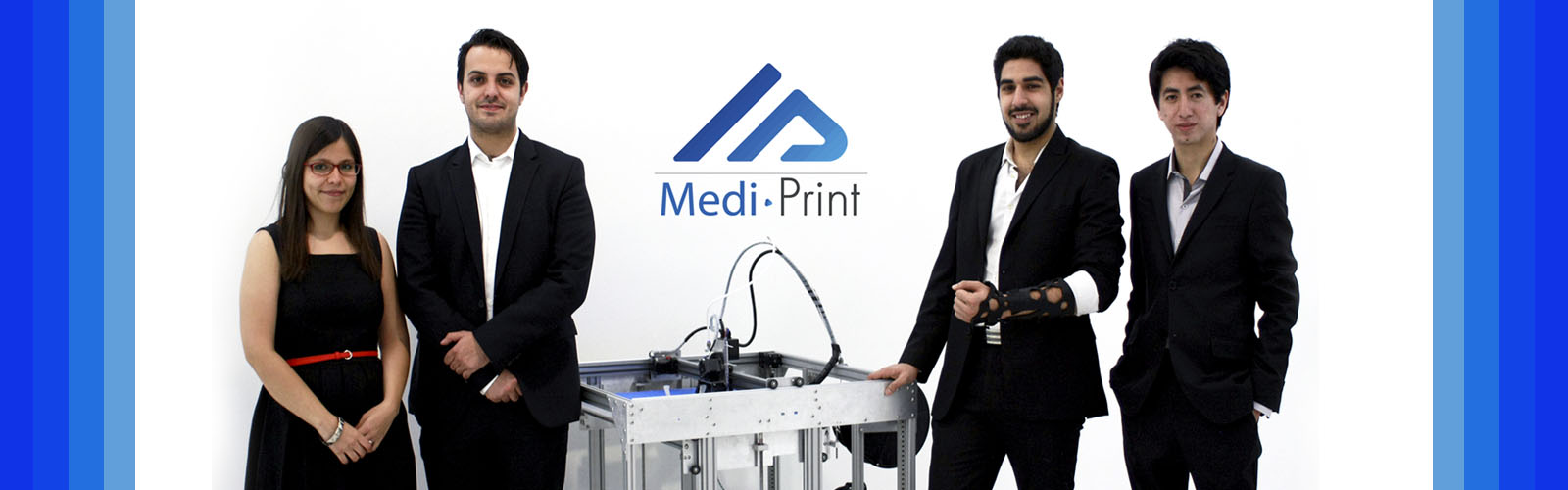

In order to make the process more convenient and faster for doctors, Badwan designed specialized software that allows the precise measurements of the device to be defined without the need of a 3D scan. The doctor simply inputs data about the patient, and the software automatically generates the optimal geometry for the 3D printed cast. Thus far, Mediprint is still in their early stages of development, and have recently raised over $8,000 on the Mexican crowdfunding platform fondeadora.mx, and have also won more funding through UNAM-based competitions. According to the MediPrint team, all of this funding will go towards increasing the 3D printing capacity for their NovaCast. Along with the rest of the Mediprint team, which includes Andrés Souza, Carlos Hansen, Ulises Martinez and Nahme Pineda, the young startup is on an innovative path towards forever changing the way we treat and heal our broken bones.